Auto-tuning (at)/auto-reset, Auto-tuning (at)/auto-reset -6, Caution – IDEC MicroSmart Pentra User Manual

Page 29: Pid m

PID M

ODULE

M

AIN

F

UNCTIONS

4-6

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

(1)

(2)

(3)

SP

AT

SP+20

(4)

(4)

Time

Temperature

C

SP-20 C

SP-20

SP

AT

(1)

(2)

(3)

(4)

Temperature

Time

C

Auto-Tuning (AT)/Auto-Reset

The optimal temperature control parameters differ depending on the characteristics of the process to control.

For PID control action, the proportional band, integral time, derivative time, and ARW are automatically

configured by performing auto-tuning (AT). For P control or PD control action, the reset value is automatically

configured by performing auto-reset.

Caution

• Perform auto-tuning (AT)/auto-reset during the trial run.

• If the auto-tuning (AT) is performed near the ambient temperature, sufficient

fluctuations cannot be given to the process, and auto-tuning (AT) may fail. In

such case, configure the P, I, D, and ARW values manually.

• Perform auto-reset when the process variable (PV) is stabilized within the

proportional band.

• Once auto-tuning (AT)/auto-reset is performed, it is unnecessary to perform

auto-tuning (AT)/auto-reset again as long as the process is unchanged.

• When voltage or current input is selected and the auto-tuning (AT) is performed,

fluctuations are given to the process at the set point (SP) regardless of AT bias.

• During program control, fluctuations are given to the process as soon as

auto-tuning (AT) is started.

Auto-tuning (AT)

In order to configure P (proportional band), I (integral time), D (derivative time), and ARW (Anti-Reset

Windup) automatically with optimal values, the auto-tuning (AT) can be performed. The auto-tuning (AT)

gives temperature fluctuation to the process to calculate those parameters. To perform an optimal

auto-tuning (AT), temperature fluctuation is given to the process when the process variable (PV) reaches

near the set point (SP). By setting the AT bias, the temperature to start giving fluctuation can be configured.

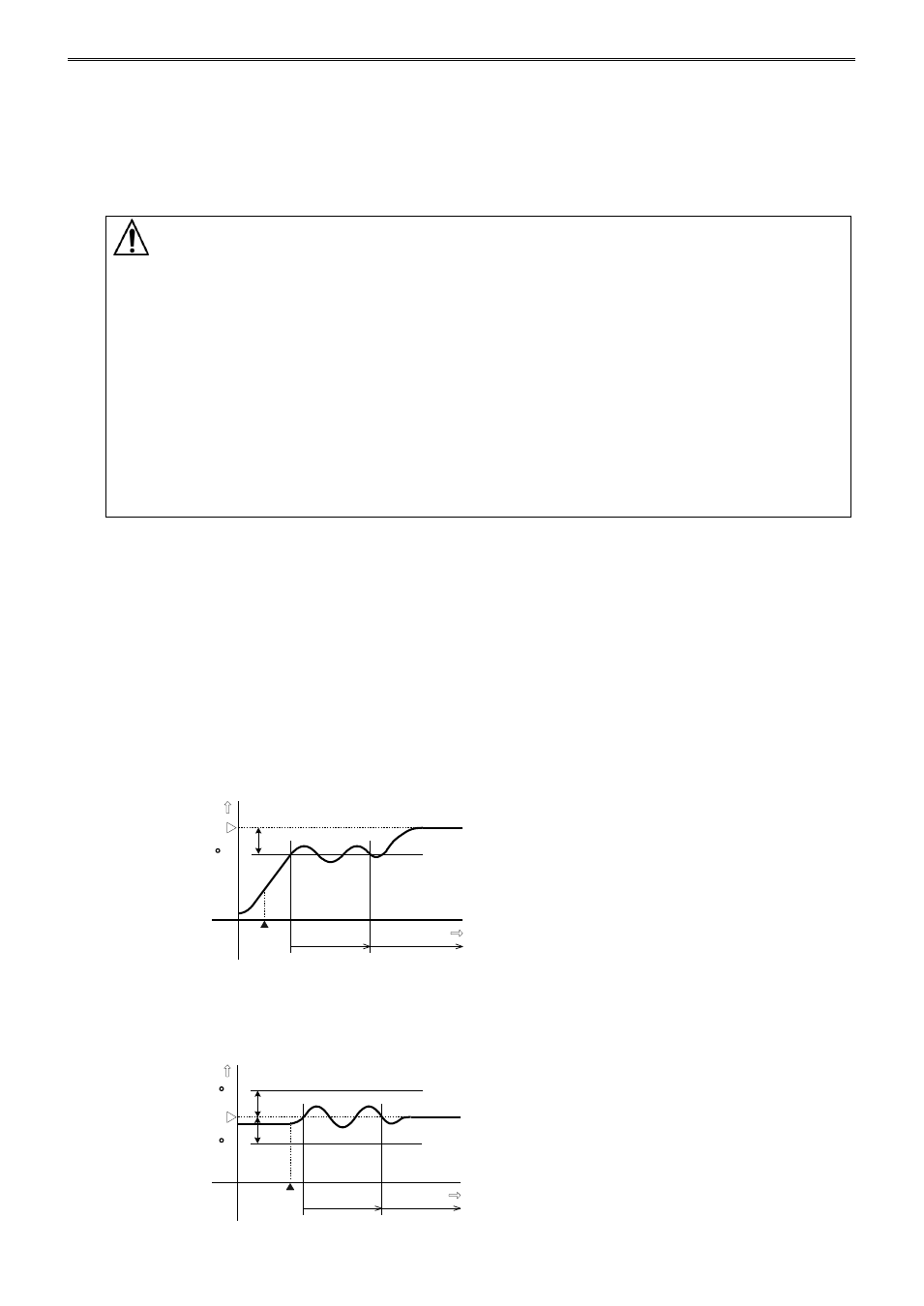

The relation between the set point (SP), AT bias, auto-tuning (AT) starting point, and fluctuation starting point

are shown below.

[Process variable (PV)

≤ Set point (SP) - AT bias value]

When AT bias is set to 20°C, the PID module starts giving the temperature fluctuation to the process at the

temperature 20°C lower from the set point (SP).

(1) Fluctuation period. PID parameters are

measured.

(2) PID parameters are calculated and auto

tuning (AT) is finished.

(3) Temperature is controlled with the PID

parameters configured with auto-tuning (AT).

(4) AT bias value (20°C)

▲ AT: Auto-tuning (AT) perform bit is turned on

[Set point (SP) - AT bias value < Process variable (PV) < Set point (SP) + AT bias value]

The PID module starts giving the temperature fluctuation to the process when the process variable (PV)

reaches the set point (SP).

(1) Fluctuation period. PID parameters are

measured.

(2) PID parameters are calculated and auto

tuning (AT) is finished.

(3) Temperature is controlled with the PID

parameters configured with auto-tuning (AT).

(4) AT bias value (20°C)

▲ AT: Auto-tuning (AT) perform bit is turned on