Application example 2, Application example 2 -8 – IDEC MicroSmart Pentra User Manual

Page 129

A

PPLICATION

E

XAMPLES

7-8

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

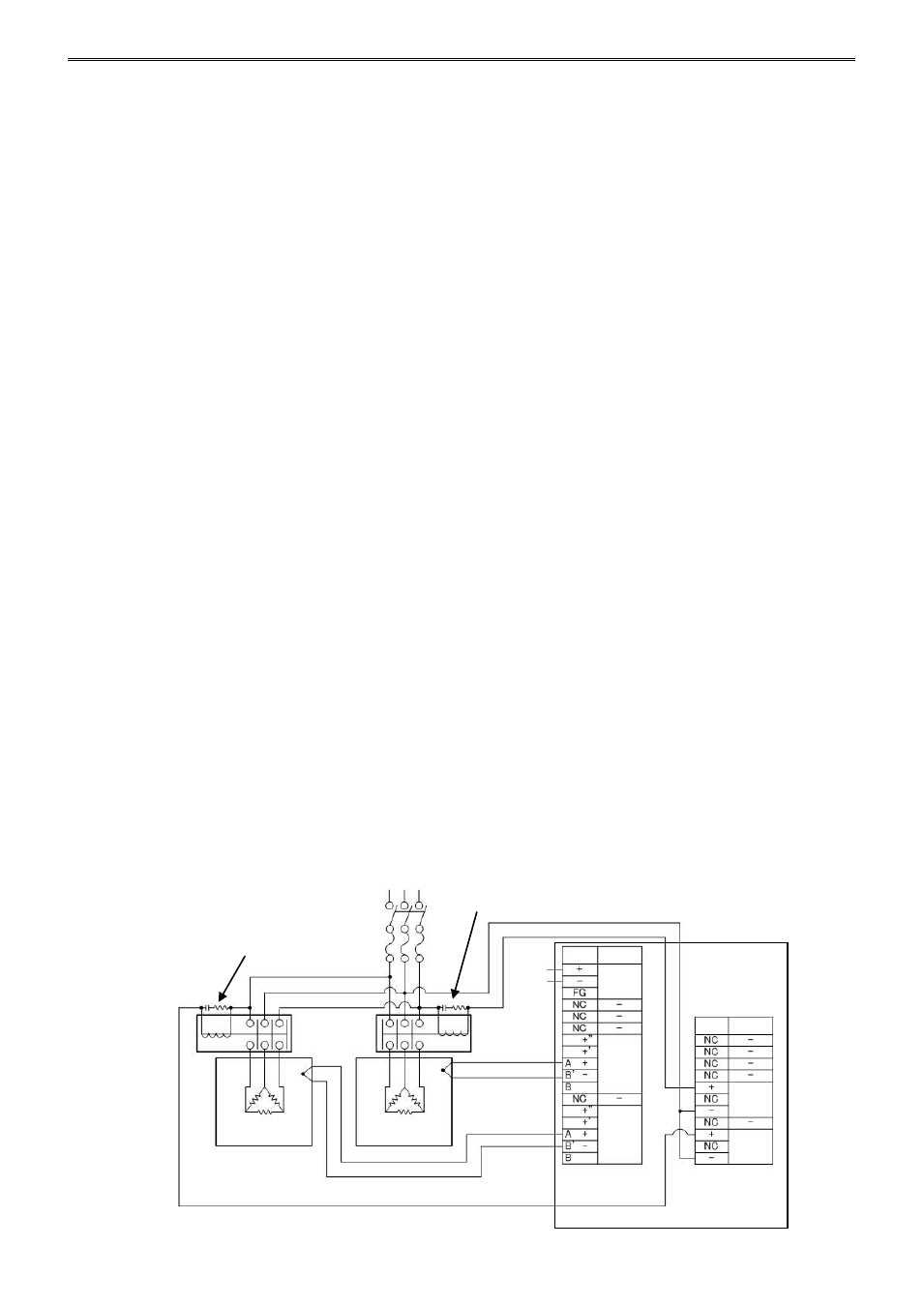

Application Example 2

This application example demonstrates the program control for a system using two electric furnaces for

ceramic industries.

• The PID module controls electric furnace 1 with CH0 control and electric furnace 2 with CH1 control using

program control.

• PID control is performed based on the temperature input to the PID module and the program pattern below.

The control output is turned on or off in accordance with the output manipulated variable (MV).

• The program pattern for the program control consists of the following 4 steps.

[Step 0]: Preheat process

Step 0 is the process to gradually raise the set point (SP) to the preheat temperature (100°C) in

60 minutes to evaporate water in the specimen and electric furnace interior. When the elapsed

time in step 0 is 60 minutes, if the process variable (PV) is less than 90°C, the PID module waits

until the temperature reaches 90°C. When the temperature reaches 90°C, the PID module

proceeds to the next step.

[Step 1]: Preheat process

Step 1 is the process to keep the preheat temperature (100°C) constant for 60 minutes.

[Step 2]: Firing process

Step 2 is the process to gradually raise the set point (SP) to the firing temperature (800°C) in 5

hours to prevent the specimen from being damaged by a rapid temperature rise. When the

elapsed time in step 2 is 5 hours, if the process variable is less than 790°C, the PID module waits

until the temperature reaches 790°C. When the temperature reaches 790°C, the PID module

proceeds to the next step.

[Step 3]: Firing process

Step 3 is the process to keep the firing temperature (800°C) constant for 30 minutes.

• PID parameters (proportional band/proportional gain, integral time, derivative time, and ARW) of each step

are automatically calculated using auto-tuning (AT).

• In CH0 control, if the process variable (PV) in step 1 becomes 110°C or higher or if the process variable (PV)

in step 3 becomes 810°C or higher, the upper limit alarm output (Q0) is turned on and the control is disabled.

• In CH1 control, if the process variable (PV) in step 1 becomes 110°C or higher or if the process variable (PV)

in step 3 becomes 810°C or higher, the upper limit alarm output (Q1) is turned on and the control is disabled.

System Configuration and Wiring

Wiring Example of the FC5A-F2MR2 [Relay output type]

Surge Absorber

Surge Absorber

3-phase

Power Supply

Electromagnetic

Switch

Electric

Furnace 2

CH0 Thermocouple

CH1 Thermocouple

+

-

+

-

Power

Supply

PID Module (FC5A-F2MR2)

Electric

Furnace 1

OUT0

OUT1

IN1

IN0

24V DC

Channel

Terminal

No.

Terminal

No.

Channel