Pid m – IDEC MicroSmart Pentra User Manual

Page 105

C

ONFIGURING

PID M

ODULE USING

W

IND

LDR

6-40

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

(20) Control Register+48: Cooling Proportional Band

The cooling proportional band can be configured when the heating/cooling control is enabled. The cooling

proportional band is the multiplication of the heating proportional band.

Example:

When the heating proportional band is 10°C and the cooling proportional band is 2.0, the cooling proportional

band will be 20°C. If cooling proportional band value is 0.5, the cooling proportional band will be 5°C.

If the cooling proportional band is 0, the cooling side control will be ON/OFF control action. If the heating

proportional band is 0, both heating and cooling side controls will be ON/OFF control action.

(21) Control Register+98: Cooling Output ON/OFF Hysteresis

Output on/off hysteresis for cooling output can be configured. When cooling control action turns from on to off

and vice versa, the span between on and off positions of the cooling output is called cooling output on/off

hysteresis.

If the cooling output on/off hysteresis is narrowed, the cooling control output switches to on or off even by a

slight variation of temperature at around the set point (SP). This frequent on/off shortens the output relay life

and may negatively affect the connected equipment. To prevent that harmful effect, the hysteresis is provided

for on/off control action.

Cooling output on/off hysteresis can be configured only when cooling control action is in ON/OFF control

(when cooling proportional band is 0).

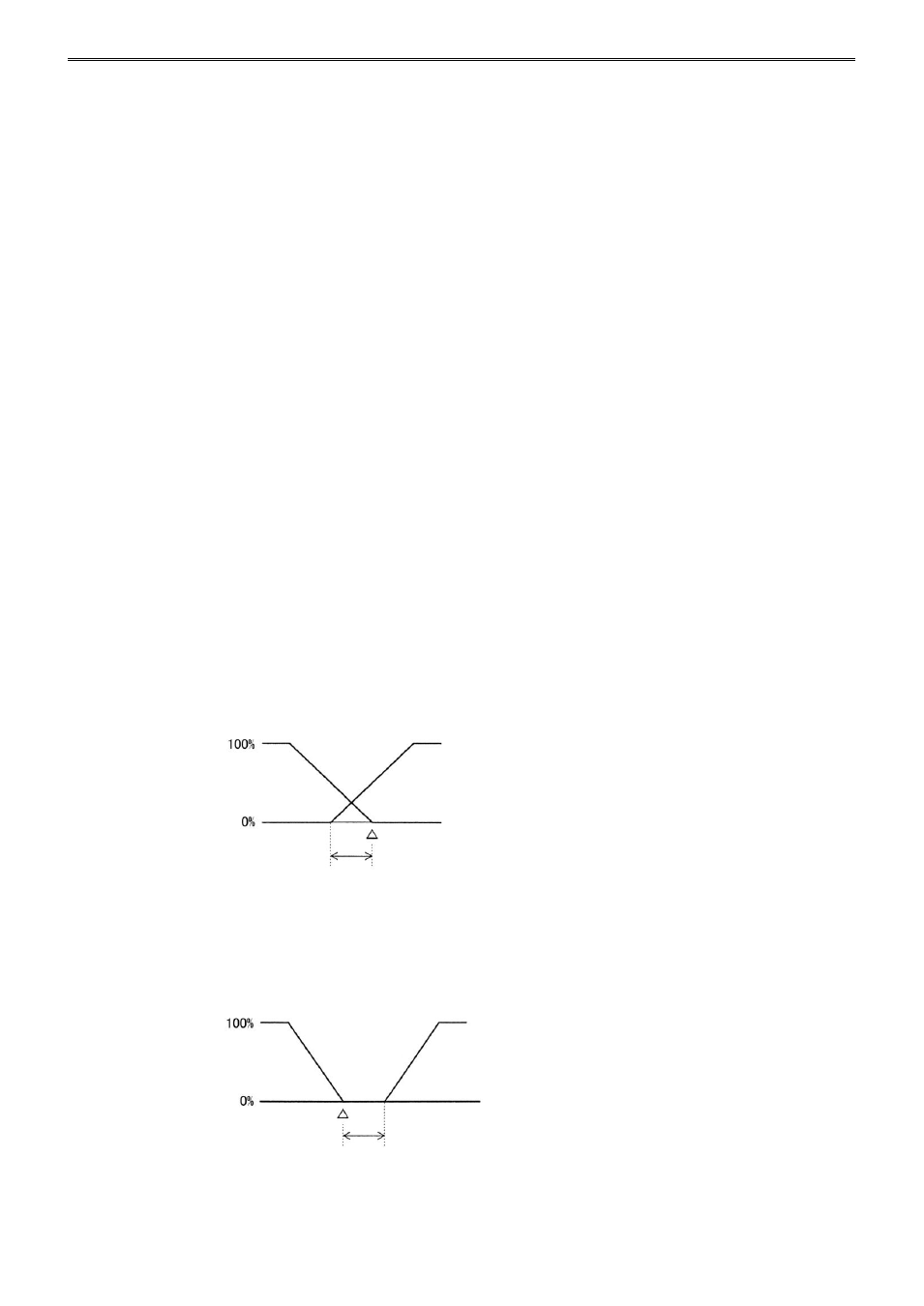

(22) Control Register+50: Overlap/Dead Band

The overlap/dead band of the heating and cooling outputs can be configured when heating/cooling control is

enabled. When the configured value is bigger than 0, the value is used as the dead band. When the configured

value is less than 0, the value is used as overlap band.

When the overlap band is configured, the area in which both heating and cooling control outputs are turned on

is generated, and the energy loss is caused. However, the overlap helps enhance the control accuracy and

accelerate the response.

When the dead band is configured, the area in which neither heating nor cooling control outputs are turned on

is generated. In the dead band, the control accuracy and responsiveness is lowered; however, the energy loss

can be suppressed.

Output manipulated

variable (MV)

Overlap Band Action

Output manipulated

variable (MV)

Dead Band Action

Heating

Output

Overlap Band

Cooling

Output

Set Point

(SP)

Temperature

Set Point

(SP)

Cooling

Output

Heating

Output

Dead Band

Temperature