50 glider model function descriptions – HITEC Eclipse 7 Pro User Manual

Page 52

50

Glider Model Function Descriptions

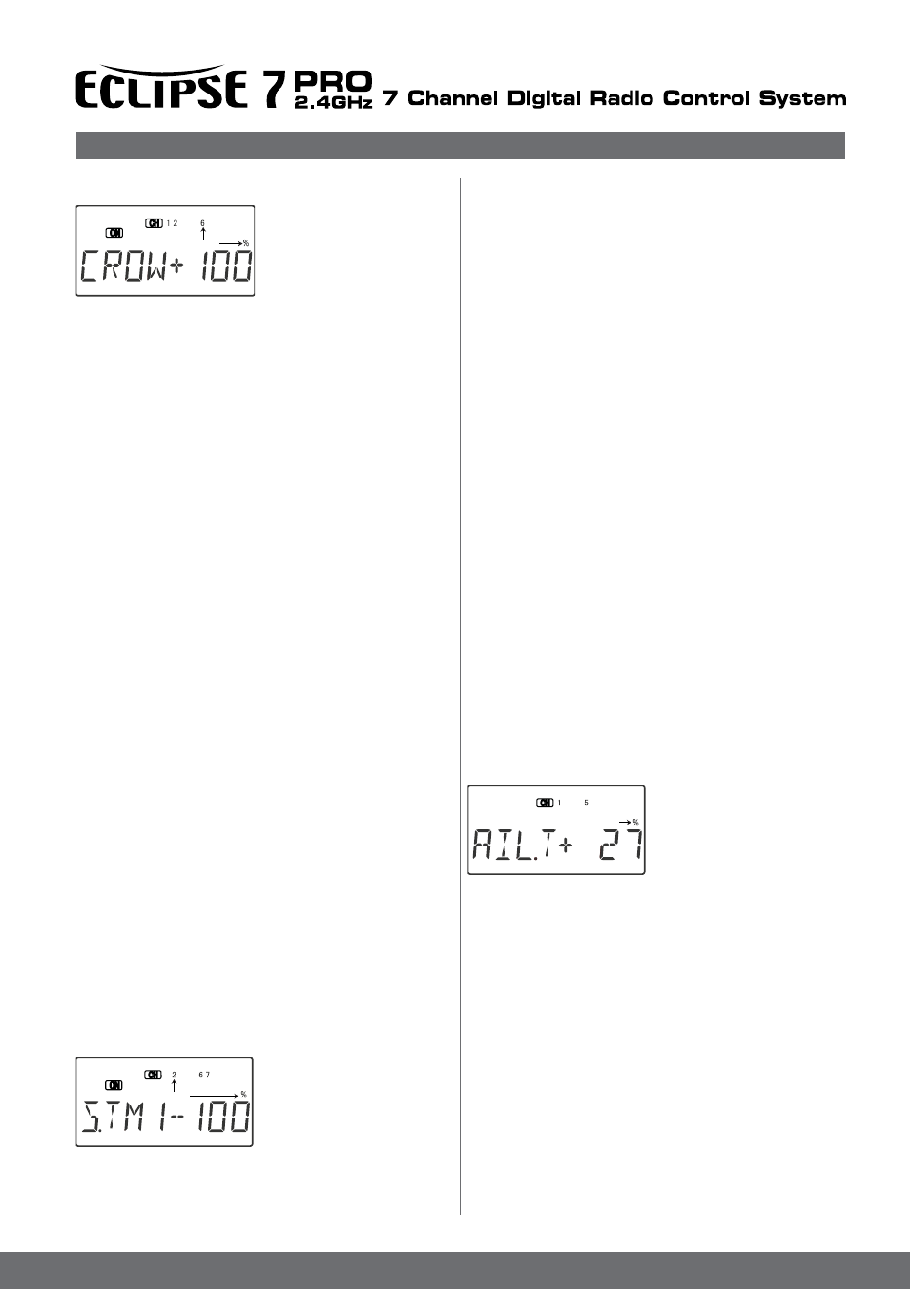

2. First, you’ll set the elevator (CH2) function offset

amount. Make sure S.TM1 is ON by moving the Flt.

Mode switch fully back. Verify it’s on by looking at the

flashing On indicator. Hit the Cursor Right key one time,

and a small arrow will appear over the numeral 2.

3. Next, set up the elevator (CH2) motion. Press the Data

+Increase or -Decrease keys to adjust the amount of

elevator offset. Use a small amount at first, as the

elevator is very effective.

4. Now set up the throws for the CH6 flap. Hit the Cursor

Right key one time, and the numeral 6 and percentage sign

will be flashing. Now use the Data +Increase or

-Decrease keys to adjust the amount of CH6 flap offset.

5. Next set up the throws for the CH7 flap. Hit the Cursor

Right key once, and the small arrow will move over the

numeral 7. Use the Data +Increase or -Decrease keys

to adjust the amount of CH7 flap offset.

6. Locate the S.TM2 menu by pressing the Up Edit key,

and then press the Active/Inhibit (Clear) key to turn it on.

Either the ‘Off’ or the ‘On’ display will be flashing,

depending on the position of the Flt. Mode switch.

7. Repeat the previous instructions for the second set of

inputs for elevator, CH6, and CH7.

AIL.T - Aileron trim

either two or four wing servos. It provides a simple way

to adjust the position of the outboard wing controls (CH1

and CH5) without resorting to the Speed Flap Trim menu.

When you adjust the Aileron Trim setting, you move the

two outboard wing controls together - they go upwards or

downwards together. In models with four wing servos,

you can use Aileron Trim together with the Dual Flap Trim

function (see below) to set any position of the wing

controls without using subtrims.

Using Aileron Trim

1. Turn on Dual Aileron

Trim by locating the AIL.T

menu with the Up Down

Edit keys.

2. Adjust the percentage to

neutralize them relative to each

other with the DATA keys

A->F - Aileron Flap mixing (4WNG only)

To roll a sailplane, we must increase the lift on one wing

and reduce lift on the other. The model will of course roll

towards the wing with reduced lift. For minimum drag

when turning, we want to have the way the lifting is done

vary smoothly along the span (i.e. zero at the root and

maximum at the tips). Unfortunately, to do this requires

a control surface that tapers from zero at the root to

maximum at the tip. Since this is impractical, we mix

from the ailerons to the flaps as shown below, so the

inner ailerons don’t move as far as the outer ones. This

is an approximation of the ideal lift for rolling, and will

reduce the drag created while banking the wings.

It’s more efficient to use both inboard and outboard wing

controls to make a turn. For a left turn, the left ailerons

go up, the right ones go down. The length of the arrows

is proportional to the control movement (notice that

to the sailplane trimming chart on page 51 for more

details.

6. Now press the Right key

to get to the flap setting

menu (the numeral 6 and per-

centage sign will be flashing

in the display). Press the

Data +Increase or -Decrease keys to set up the throws

for the flaps as desired. Move the throttle stick and be

sure the flaps go down with crow. If they don’t go down,

but go up instead, press the Clear Active/Inhibit key and

then press the other Data key to achieve the desired

down flap travel (this may depend on servo orientation).

You’ll probably want as much flap motion as possible -

90 is great if you can get it. Like the ailerons, you set

both flap offsets at the same time.

7. If you can’t get enough travel, go to the EPA menu and

be sure CH6 and CH7 are set as high as possible to get

90 flap travel. Of course, you can reduce them to get

the amount of travel that you’d like at full crow, but this is

better done in the Crow menu as given in the previous

step. It may be helpful to use long servo arms on the flap

servos to increase their effective throw.

Remember to try your crow setup out at higher altitudes

to verify that the trim doesn’t change rapidly. If you want

to steepen the descent, increase the flap downward

deflection while increasing the up aileron movement.

Caution: when setting up crow, do not call for too much

aileron “up” travel, or you’ll lose roll authority, and this

occurs at a crucial time, when your model is flying

relatively slowly on a landing approach. Always make

changes in small increments, don’t try to do it “all at once.”

S.TM1, 2 - Speed Flap Trim offsets (Camber mix) 1, 2 (4WNG

only)

Speed Flap Trim Offsets, together with flight conditions,

are a way to set up gliders with four wing servos(4WNG).

They do not appear in the two wing servo (2WNG) menu.

Speed Flap Trim offsets are used to offset the positions of

the elevator servo (CH2) and the inboard flaps (CH6 and

CH7) by flipping the Flt. Mode switch.

Together with the Flight Condition menus (FLT.C), you

can command any position of the inboard flaps, ailerons,

and elevator by flipping the Flt. Mode switch, and without

using Speed Flap Trims. Speed Flap Trim offset #1 is On

when the Flt. Mode switch is fully back, and is commonly

used for the “speed” mode, where the trailing edge is

reflexed. Speed Flap Trim offset #2 is On when the Flt.

Mode switch is fully forwards, and is commonly used for

setting up offsets needed for good launches.

Setting Up Speed Flap Trim Offsets

1. Start by locating the

S.TM1 menu with the Up

Down Edit keys, then

pressing the Active/Inhibit

(Clear) key. Either the ‘Off’

or the ‘On’ display will be flash-

ing, depending on the

position of the Flt. Mode switch. Also, the indicators for

CH2, CH6, and CH7 will appear at the top of the display.

Flashing

Flashing

Flashing