47 competition glider quick setup instructions, Glider model function descriptions – HITEC Eclipse 7 Pro User Manual

Page 49

47

Competition Glider Quick Setup Instructions

edge should raise no more than 1/16” (1.5 mm), or you’ll

gain more drag than penetration ability.

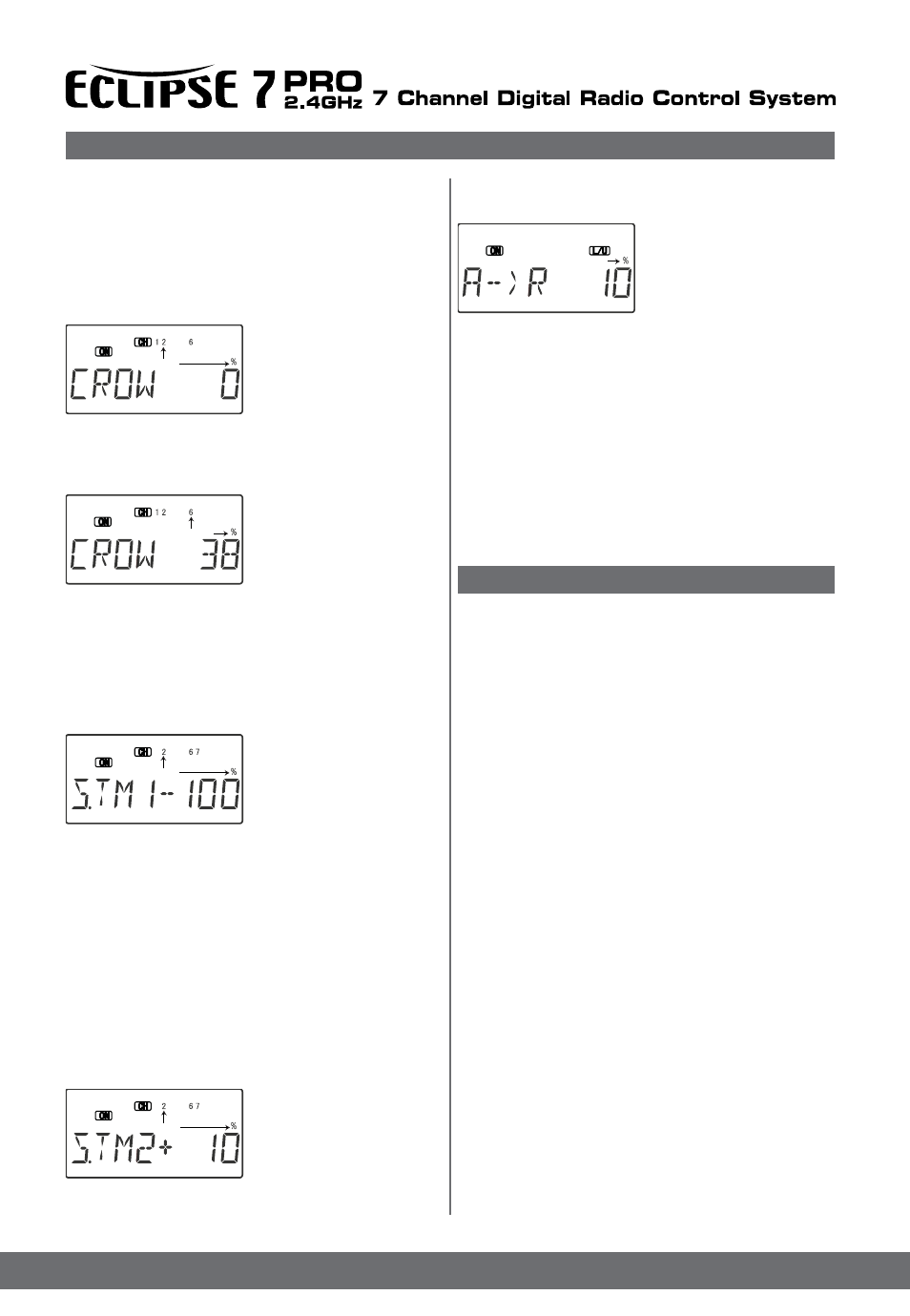

31. If desired, add aileron rud-

der coupling (A->R) for

coordinated turns. This setting is

highly dependent on the model

configuration.

Usually only a small amount of

rudder is needed,

especially if a large amount of differential is present, so

start out with 10-15%.

Carefully observe the direction of the fuselage relative to

the thermal turn the model is making. If the nose points

towards the inside of the circle, the coupling is too high,

and if it points towards the outside of the circle, you need

more coupling. When everything is set properly, the

fuselage will be tangent to the thermal turn circle (see

page ?? for more details). While you are flying, watch

for trim changes during launch and crow control actions

and set the compensations to cancel them out. You may

wish to refer to the sailplane trimming chart presented

earlier.

EPA - End point adjust

See ACRO instructions on page 27

D/R - Dual Rates

See ACRO instructions on page 27

EXP - Exponential

See ACRO instructions on page 30

FLT.C - Flight Conditions

See ACRO instructions on page 31. There are three

FLT.C settings available in the GLID menus. Note that

in addition to the FLT.C features described there, you can

also use the STM.1 and STM.2 subtrim offset functions

to program different controls move to new positions.

Together, these can be used to set up launch and speed

control positions and offsets for sailplanes. The trim lever

for the flap stick controls the neutral position of both flaps

if 4WNG is on. In the GLID menus with the 4WNG

option on, the flight condition menus allow you to offset

the trim positions inputted by the trim levers for channels

1, 2, 4, and 6. The Speed Flap Trim offset functions

allow you to also offset the position of the elevator servo

(CH2) and the dual flap servos (CH6 and CH7). Speed

Flap Trim offset functions are described later.

STRM – Subtrim

See ACRO instructions on page 31.

REV - Servo Reversing

See ACRO instructions on page 32.

PMX1 to PMX5 - Programmable Mixing Functions

See ACRO instructions on page 32.

26. Now you may set up the throw for the elevator, but

it usually doesn’t take much, and too much will be

uncontrollable. We suggest you set this amount after

you’ve flown and know how much elevator motion is

needed to trim. Press the Cursor Right key once to get

to the elevator setting menu (the Numeral 2 and percentage

sign will be flashing). Set the desired number with the

Data +Increase or -Decrease keys. For starters, use

zero or very little elevator

compensation until you fly

and determine what is

needed: if the model pitches

up with crow, add down

elevator compensation and if it

pitches down wards, add

some up compensation. Make only small changes in

compensation because it has a big effect on trim. Refer to

the sailplane trimming chart for more details.

27. (4WNG only) Now set

up the throws for the flaps

as desired. Press the

Cursor Right key once

to get to the flap setting

menu (the Numeral 6 and per-

centage sign will be flashing).

Set the desired number with the Data +Increase or

-Decrease keys. Move the throttle stick and be sure the

flaps go DOWN with crow. If they don’t, change the sign

(this may depend on servo orientation). You’ll probably

want as much flap motion as possible - 90 is great if you

can get it. Like the ailerons, you set both flap offsets at

the same time.

28. (4WNG only) Then, using

Subtrims, fine tune to get

neutral flaps on both sides. Use

EPAs to get 90 flap

travel (or the amount of travel

that you’d like) at full crow.

It may be helpful to use long

servo arms on the flap servos to increase their effective throw.

29. (4WNG only) You can use the S.TM1 (launch)

preset for high launches.

You can set the two flaps (CH6 and CH7) to drop

for more lift, and trim with elevator (CH2). Increase the

up- elevator preset in small increments until the plane

launches as steeply as you like, or add down elevator if

the model weaves back and forth or is hard to control

(remember to use the rudder stick, or rudder coupling,

during the launch). A well-trimmed model may actually

have some down elevator mixed in for launching.

Remember that to get the S.TM1 function to turn on, you

have to flip the Flt. Mode switch Back.

30. (4WNG only) You may

also set up the speed mode

presets (S.TM2) for high speed

cruise between

thermals. Reflex the entire

trailing edge a very small

amount -10% or even less all

the way across is recommended for starters. The trailing

Glider Model Function Descriptions

Flashing

Flashing

Flashing

Flashing

Flashing