Advanced troubleshooting, Adult supervision recommended) – Elenco Snap Circuits® Deluxe Sound & Light Combo User Manual

Page 24

-23-

Advanced Troubleshooting

(Adult supervision recommended)

ELENCO

®

is not responsible for parts

damaged due to incorrect wiring.

If you suspect you have damaged parts,

you can follow this procedure to

systematically determine which ones need

replacing:

(Note: Some of these tests connect an LED directly

across the batteries without another component to

limit the current. Normally this might damage the

LED, however Snap Circuits

®

LEDs have internal

resistors added to protect them from incorrect

wiring, and will not be damaged.)

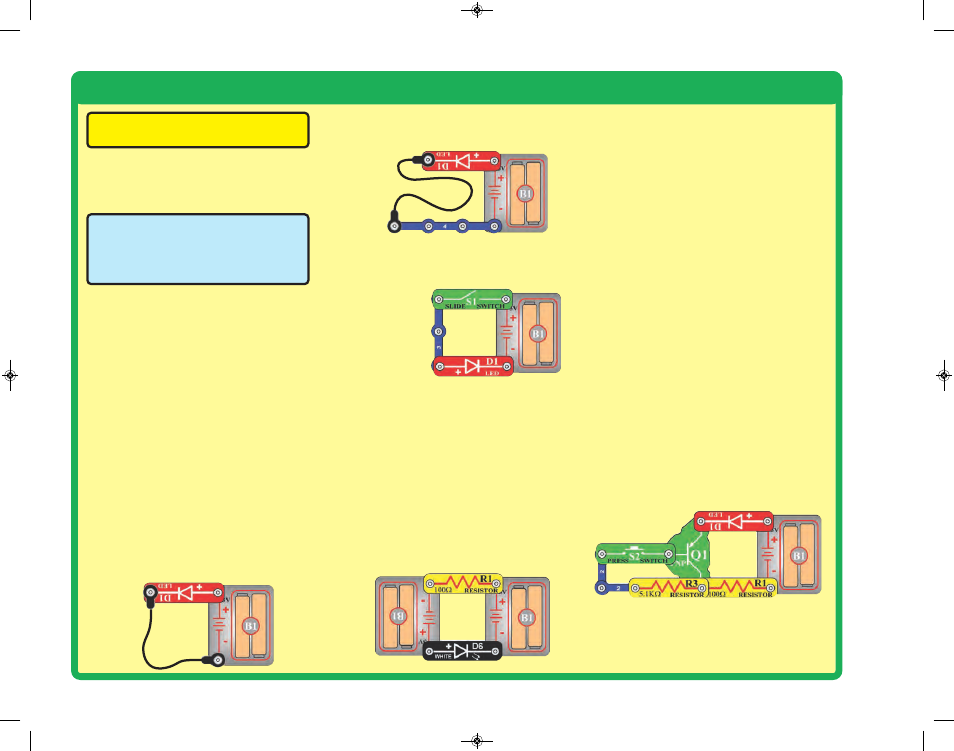

1.

Red LED (D1), motor (M1), speaker

(SP2), and battery holder (B1):

Place

batteries in holder. Place the red LED

directly across the battery holder (LED + to

battery +), it should light. Do the same for

the motor, it should spin. “Tap” the speaker

across the battery holder contacts, you

should hear static as it touches. If none

work, then replace your batteries and

repeat. If still bad, then the battery holder

is damaged.

If the motor spins but does not balance the

fan, check the black plastic piece with three

prongs on the motor shaft, and replace it if

it is damaged (this kit includes a spare). To

replace, pry the broken one off the motor

shaft using a screwdriver, then push the

new one on.

2.

Red & black jumper wires:

Use this mini-

circuit to test each jumper wire, the LED

should light.

3.

Snap wires:

Use this mini-circuit to test

each of the snap wires, one at a time. The

LED should light.

4.

Slide switch (S1) and Press switch (S2):

Use this mini-circuit; if the LED doesn’t light

then the slide switch is bad. Replace the

slide switch

with the press

switch to test it.

5.

100W (R1) and 5.1kW (R3) resistors:

Use

the mini-circuit from test 4 but replace the

switch with the 100W resistor (R1); the LED

will be bright if the resistor is good. Next

use the 5.1kW resistor in place of the 100W

resistor; the LED should be much dimmer

but still light.

6.

White LED (D6) and color LED (D8):

Use

this mini circuit; if the white LED doesn’t

light then D6 is bad. Replace the white LED

with the color LED; it should change colors

in a repetitive pattern, otherwise D8 is bad.

7.

500kW adjustable resistor (RV3),

Microphone (X1), Photoresistor (RP),

and Phototransistor (Q4):

Use the mini-

circuit from test 6 but replace the 100W

resistor with RV3. Turning RV3’s knob all

the way to the left (counter-clockwise)

should make the LED dim or off; otherwise

RV3 is bad. Next, replace RV3 with the

microphone (+ on right); if blowing into the

microphone does not change the LED

brightness then X1 is bad. Next, replace

the microphone with the photoresistor (RP)

or phototransistor (Q4, + on right). Waving

your hand over the RP/Q4 (changing the

light that shines on it) should change the

brightness of the LED or that part (RP or

Q4) is bad.

8.

Adjustable resistor (RV):

Build project

160, but use the red LED (D1) in place of

the color LED (D8). Move the resistor

control lever to both sides. When set to

each side, one LED should be bright and

the other off (or very dim); otherwise RV is

bad.

9.

PNP transistor (Q1):

Build the mini-circuit

shown here. The red LED (D1) should only

be on if the press switch (S2) is pressed. If

otherwise, then Q1 is damaged.

SCC-350_Manual_Part_A.qxp 7/25/14 2:39 PM Page 24