Section 7.2- electronic governor, General, Lirj – Generac 86640 User Manual

Page 77: Governor actuator relay, Description, Testing, Governor actuator adjustment, Electronic governor setup

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 7.2- ELECTRONIC GOVERNOR

General

Some industrial mobile (IM) series generators may be

equipped with an electronic engine governor system. The

system consists of the following major components:

n A 12 volts DC Governor Actuator Relay (GAR).

■ n An Electronic Governor Actuator (EGA),

n An Electronic Governmor Control circuit board (EGC).

n A Magnetic Pickup assembly (MPU).

n Interconnecting wiring.

Figure 4 is an operating diagram of the electronic gover

nor system. Operation may be briefly described as follows:

1. During engine startup and running, an Engine Control

circuit board delivers 12 volts DC to a GOVERNOR ACTUA

TOR RELAY (GAR) via Wire No. 14. The Relay energizes

and its normally-open contacts close.

2. When the Relay contacts close, 12 volts DC is delivered to

the ELECTRONIC GOVERNOR CONTROL (EGC) circuit

board, to turn the governor system on.

3. Engine speed information is delivered to the ELECTRONIC

GOVERNOR CONTROL (EGC) circuit board from a MAG

NETIC PICKUP (MPU). This “actual* speed is electronically

compared to a "reference” speed that has been preset on the

circuit board.

4. If any difference exists between “actual" and "reference"

speed, the ELECTRONIC GOVERNOR CONTROL (EGC)

board sends speed correction signals to an ELECTRONIC

GOVERNOR ACTUATOR (EGA).

5. The ELECTRONIC GOVERNOR ACTUATOR (EGA) is

mechanically linked to the carburetor throttle valve.

Figure 4. Governor System Schematic

GOVERNOR

CIRCUIT

BOARD

1_ 5

4

3

2

1 _|

169

?

- 0 - n

166

79

I O-

LirJ

GOVERNOR

168 RELAY

-15

+12 VDC

rh

1-169

-TO GOVERNOR ACTUATOR

-79 —

FROM RPM SENSOR

Governor Actuator Relay

DESCRIPTION;

See Figure 5. The Relay is housed in the generator

control console. The Relay coil is energized when 12 volts

DC is applied at its Terminal A and the circuit is completed

through the coil to Terminal B and to ground.

TESTING:

To test the Relay, apply +12 volts DC to Relay Terminal

A and -12 volts DC to Terminal B. The Relay coil should

energize and normally-open Relay contacts 4 and 7 should

actuate closed.

With the Relay coil energized, a VOM connected across

Relay Terminals 4 and 7 should read “continuity“.

With the Relay coil de-energized, a VOM connected

across Relay Terminals 4 and 7 should read "infinity".

Figure 5. Governor Actuator Relay

COIL

NORMALLY-OPEN

CONTACTS

NORMALLY-CLOSED.

CONTACTS

A. Schematic

ysj

-nr

B. Pictorial

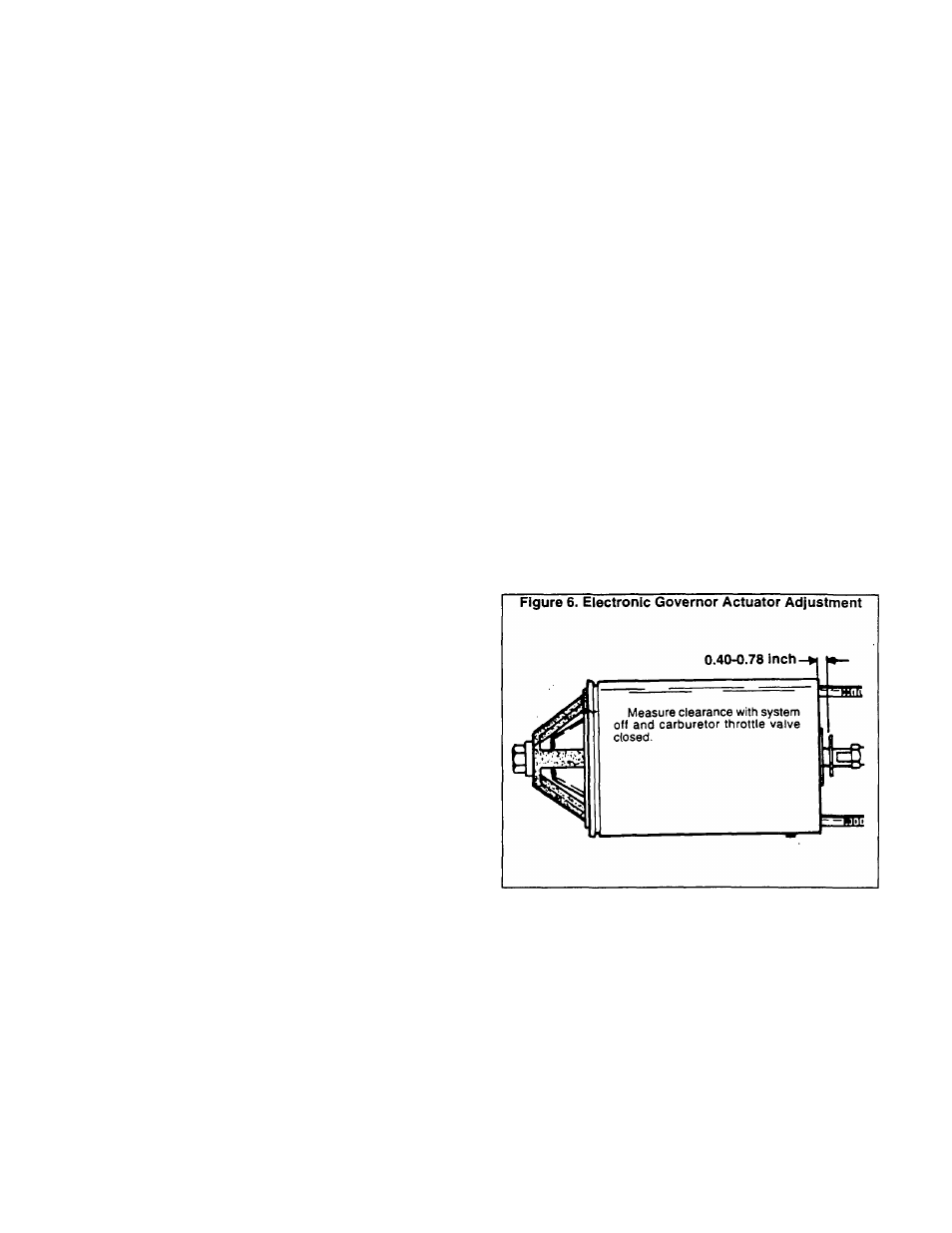

Governor Actuator Adjustment

With the engine shut down, adjust the length of the

Electronic Governor Actuator (EGA). With the carburetor

throttle valve closed, adjust so that approximately 0.40-0.78

inch (1-2mm1 of clearance exists between the EGA stop

washer and the EGA body. See Figure 6.

Electronic Governor Setup

The Electronic Governor Control (EGC) circuit board is

housed in the generator control console (see Figure 7). All

circuit board adjustments for new generators have been

completed at the factory and no additional adjustment should

be required. If the circuit board must be replaced, adjust the

governing parameters as follows:

1. See Figure 7. Set the speed pot (R5) fully counterclock-

wise.

2. Set all other potentiometers (R12, R13, R22, R26) to their

mid-point.

Page 7.2-1