Valve inserts, Camshaft bearing clearance – Generac 86640 User Manual

Page 35

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

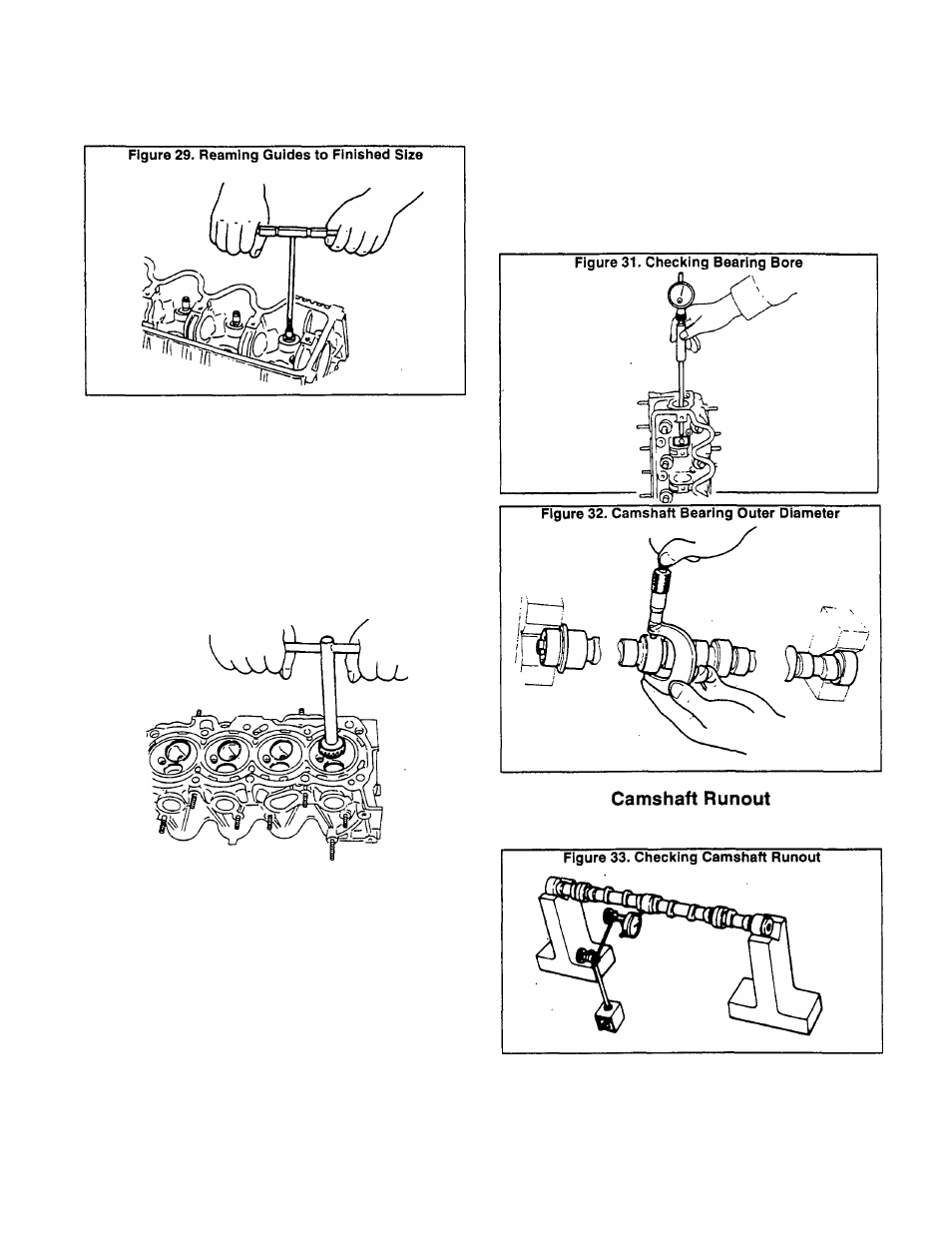

5. Ream the valve guides to a finished size of 0.2758-0.,2764

inch (7.005-7.020mm).

Valve Inserts

Inspect valve inserts for evidence of pitting at valve

contact surfaces. Reseat or replace, if worn or pitted exces

sively. The following rules apply:

D When repairing valve inserts, first check the valve and

valve guide for wear. If worn, replace them. Then, correct

the valve seat.

□ When cutting, use both hands for more uniform cutting.

Figure 30.

If necessary, replace valve inserts as follows:

1. Ream the cylinder head recess.

2. Heat the cylinder head to 302‘-320’ F. (150'-160‘ C.).

3. Install the insert. Make sure it bends at bottom face of its

recess and caulk at more than 4 places.

4. Use a suitable tool to grind newly fitted valve seats. Grind

the seats to the specifications listed in the applicable SPEC

IFICATIONS chart.

5. Apply a small amount of valve grinding compound to the

valve contacting face and place valve into guide.

Camshaft Bearing Clearance

Check camshaft bearing clearance (Figure 31). Check

both the bore and the bearing outside diameter (O.D.). The

difference between the two measurements is the bearing

clearance. Maximum bearing clearance is shown below:

MAXIMUM CAMSHAFT BEARING CLEARANCE

0.0059 Inch (0.15mm)

Use a suitable measuring device to check camshaft

runout (Figure 33).

Page 2.3-3