Crankshaft, Inspection (continued) – Generac 86640 User Manual

Page 44

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

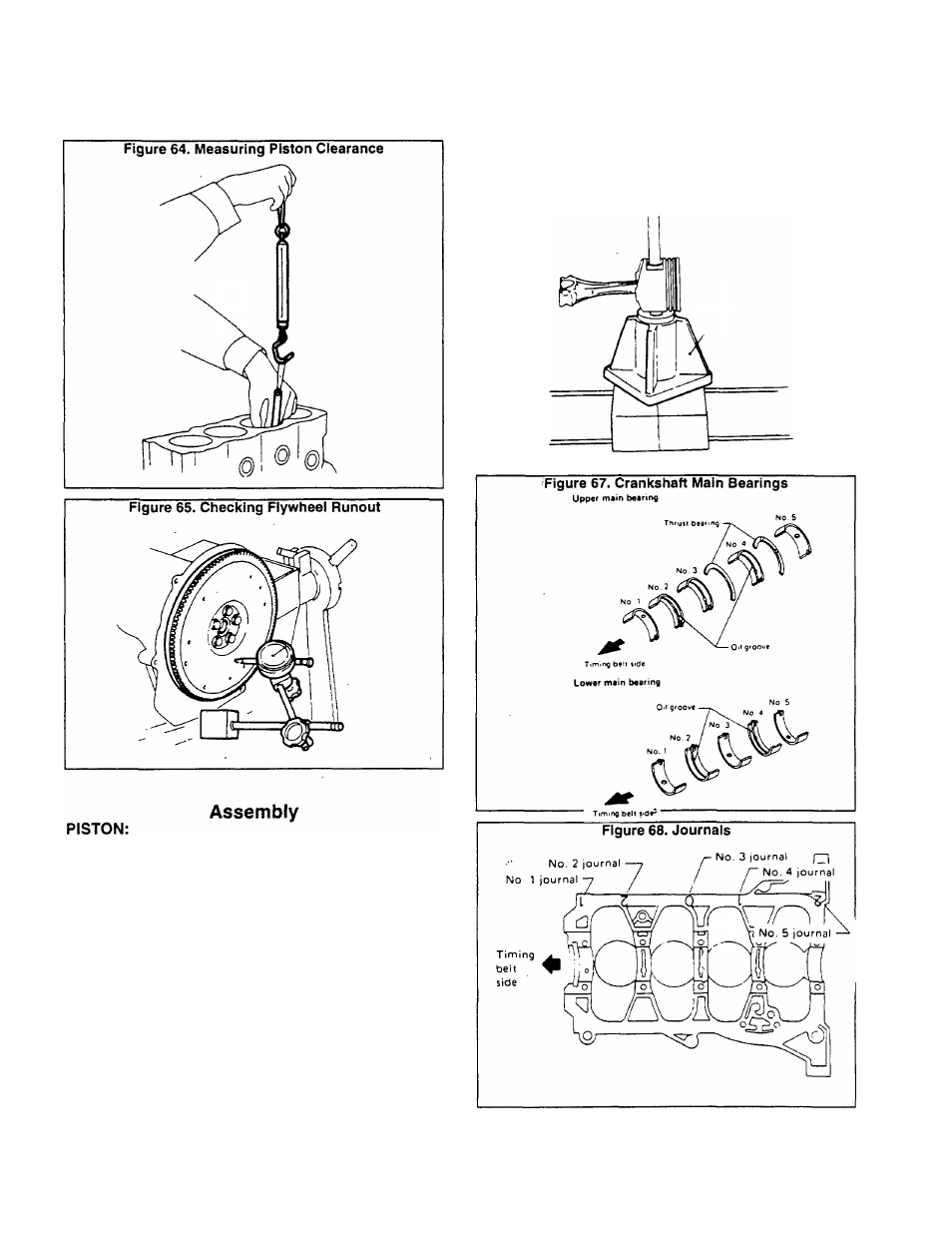

Inspection (Continued)

Numbers that correspond to the cylinder number are

stamped on connecting rods and connecting rod caps. Pis

tons, connecting rods, connecting rod caps and bearings

should be installed only in the correct cylinder. DO NOT

COMBINE PARTS FROM DIFFERENT CYLINDERS. When

pressing the piston pin into the connecting rod (Figure 66),

apply oil to the pin and to small end of connecting rod.

CRANKSHAFT:

Place main bearings in their proper position on the

cylinder block. If the crankshaft, cylinder block and main

bearings are to be replaced, you must select proper main

bearing thicknesses.

When either the crankshaft, cylinder block or main bear

ings are to be re-used, it is necessary to measure main

bearing thickness with Plastigage".

Numbers are stamped on the engine which indicate

cylinder block main journal. Measure each bore separately.

Each crankshaft has stamped numbers which indicate

main journal dimensions. Each journal is measured sepa

rately.

Select the correct main bearing thickness and order from

the parts breakdown.

Figure 66. Piston Pin Installation

Page 2.6-4