Bearing clearance, Inspection (continued) – Generac 86640 User Manual

Page 42

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Inspection (Continued)

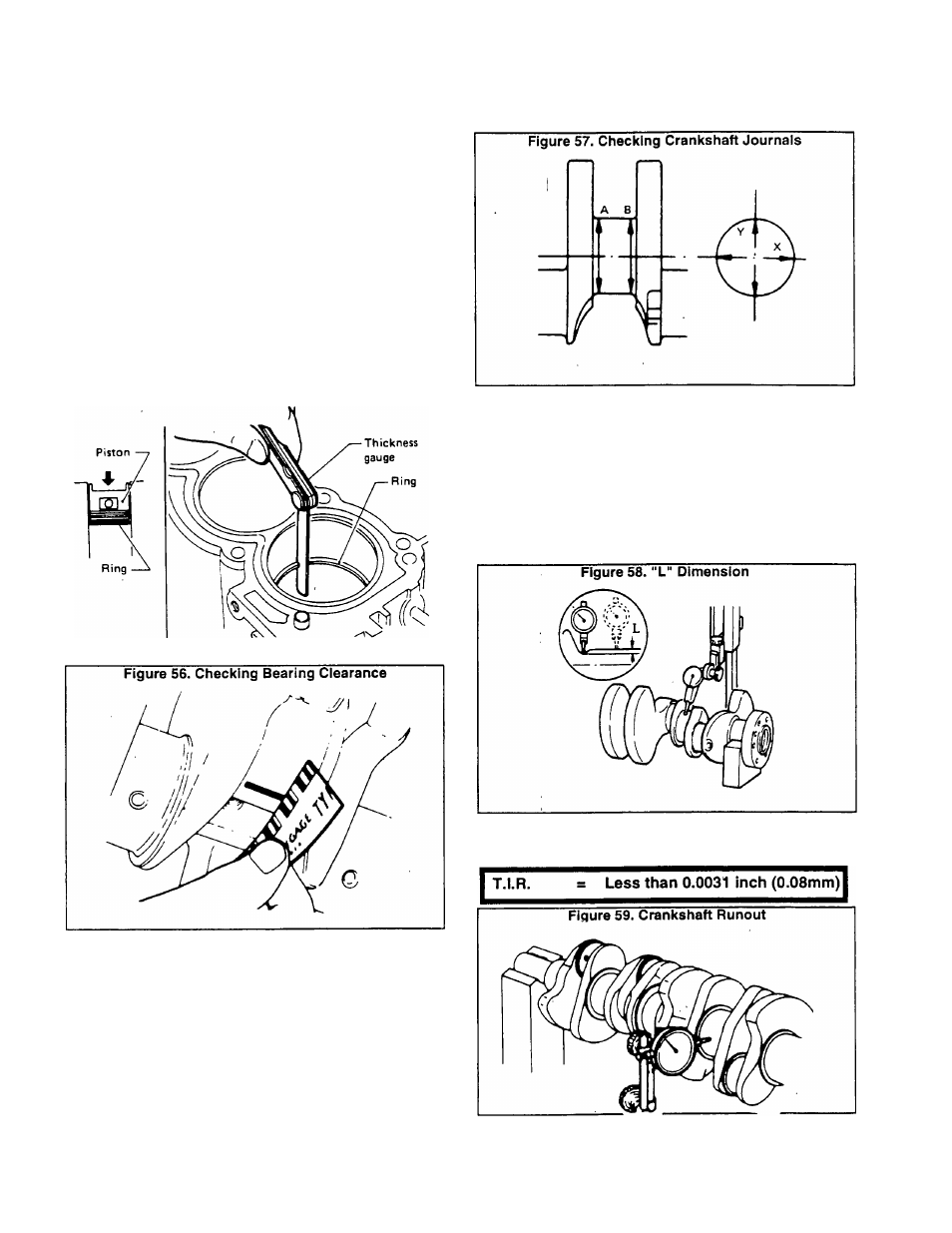

a. DO NOT turn the crankshaft or connecting rod when

Plastigage^ is being inserted.

b. When bearing clearance exceeds the specified limit,

check that the correct bearing has been installed. If exces

sive clearance still exists, use a thicker main bearing or an

undersize bearing to obtain correct clearance.

BEARING CLEARANCE

Main Bearing= 0.0012-0.0020 Inch (0.03-0.05mm)

Limit = 0.0030 inch (0.075mm)

Connecting

Rod Bearing= 0.0008-0.0024 Inch (0.02-0.06mm)

Limit = 0.0047 inch (0.12mm)

Figure 55. Checking Ring Gap

5. Inspect crankshaft journals for scoring, bias, wear or

cracks. Minor defects can be corrected using fine crocus

cloth. Use a micrometer to check journals for taper and

out-of-round. See Figure 57.

Out-of-Round (X-Y) = 0.0004 Inch (0.01mm)

Taper (A-B) = Less than 0.0008 inch (0.02mm)

6. When regrinding crankpin journal, measure the “L° dimen

sion in the fillet roll (Figure 58). The measured value must

exceed the specified limit. If measurements are within the

specified limit, DO NOT regrind.

NOTE: DO NOT grind off the fillet roll. Refer to applicable

SPECIFICATIONS chart for regrlndlng crankshaft and

available service parts.

7. Check crankshaft runout. “T.I.R." stands for "Total

Indicator Reading".

Page 2.6-2