Introduction, Fuel solenoid assembly, Vaporizer-regulator assembly – Generac 86640 User Manual

Page 68: Carburetor assembly, Description, Adjustments

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 6.2- LIQUID WITHDRAWAL SYSTEMS

Introduction

Figure 8 (next page) is an Exploded View of a typical

LIQUID WITHDRAWAL type gaseous fuel system. Major

components of the system include the following:

D Fuel Solenoid Assembly,

n Vaporizer-Regulator Assembly,

n Carburetor Assembly.

D

Air Cleaner Assembly,

n Interconnecting lines and fittings.

Fuel Solenoid Assembly

See Item 12, Figure 8. The electrically actuated fuel

solenoid is energized open, de-energized closed. Mainte

nance on this part Is generally limited to replacement of the

entire solenoid assembly.

NOTE: If the fuel solenoid assembly must be replaced,

use only an assembly that Is useable with a liquid with

drawal system. Fuel solenoids are not Interchangeable

between liquid and vapor withdrawal systems. Fuel

solenoids used on liquid withdrawal systems must be

rated at a much higher pressure than vapor withdrawal

solenoids.

Vaporizer-Regulator Assembly

The vaporizer-regulator included with the Model 9052 LP

gas conversion kit is an IMPCO Model JB. The vaporizer-reg

ulator must perform the following functions:

n It must positively stop the flow of gas when the engine is

not running.

D At the slightest vacuum, the regulator metering valve

must move off its seat and allow gas flow to the engine,

n Heated engine coolant, passing through the vaporizer-

regulator, must vaporize the liquid fuel before it reaches

the carburetor.

See Figure 6. Engine coolant lines connect to the vapor

izer-regulator, as well as inlet and outlet lines for LP gas.

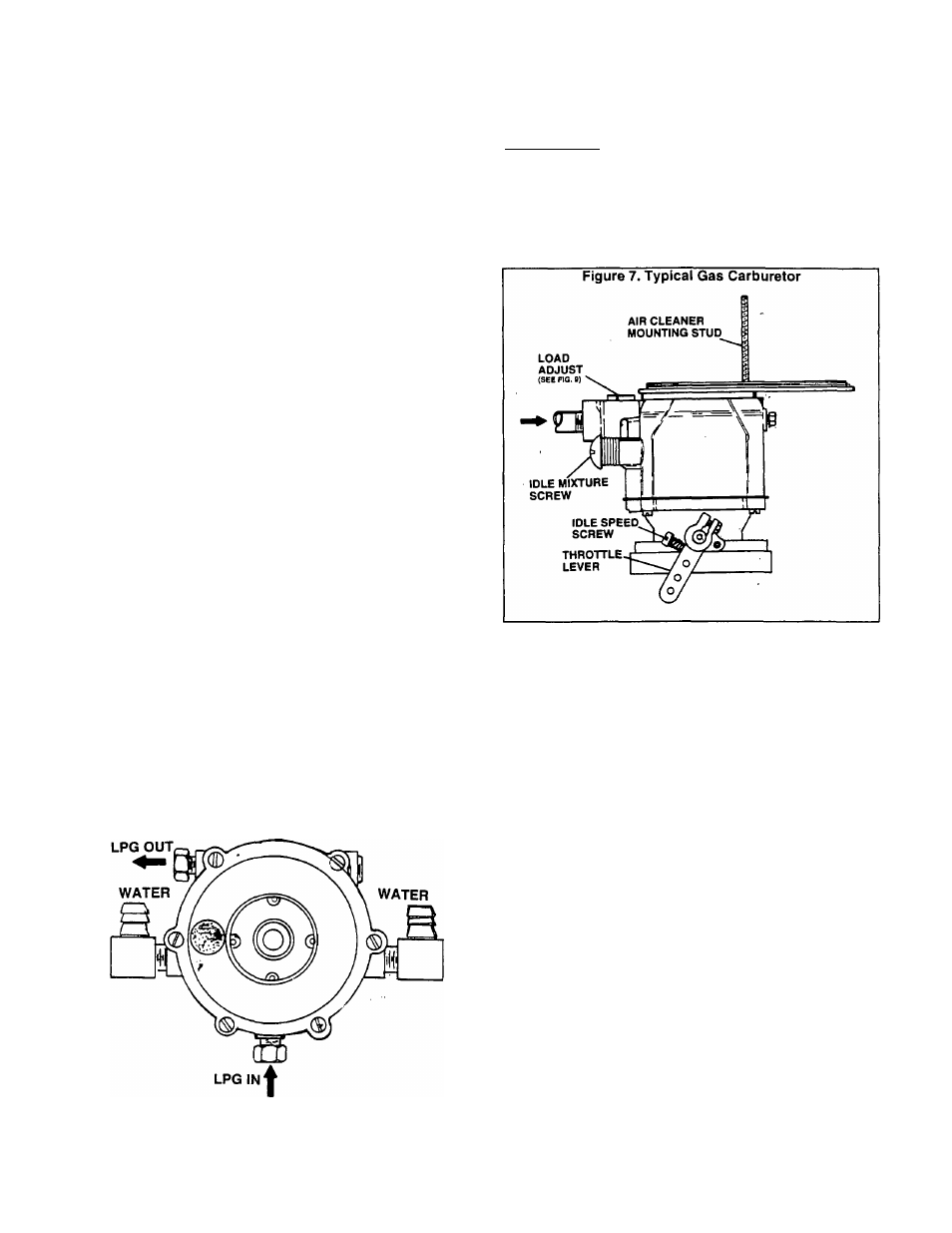

Figure 6. Vaporizer-Regulator

Carburetor Assembly

DESCRIPTION:

The carburetor assembly included with the Model 9052

gas conversion kit is an IMPCO Model CA50-506. See

Figure 7.

Vaporizer-regulator and carburetor operation are de

scribed under "GAS (^ARBURETION" on Page 6.1-2.

The carburetor is equipped with (a) an idle mixture ad

justment, and (b) a load adjustment.

ADJUSTMENTS:

Idle Mixture: This adjustment affects fuel-air mixture

only when the engine is running at idle speed. It has no affect

on operation at the engine’s normal rated speed of approxi

mately 1800 rpm and, for that reason, adjustment is not

required. However, if you wish to adjust idle mixture, proceed

as follows:

1. Connect an AC frequency meter to the generator’s AC

power output leads.

2. Disconnect all electrical loads from the generator.

3. Start the engine, let it stabilize and warm up at no-load.

4. Reduce engine speed until frequency meter reads approx

imately 30-33 Hertz.

5. Slowly turn the idle mixture screw clockwise until engine

starts to run rough. Then, turn the screw counterclockwise

until engine again starts to run rough. Finally, turn the screw

clockwise until smooth operation is obtained.

Load Adjustment: This is an adjustment of fuel-air

mixture with the rated load of the unit applied. Complete the

adjustment as follows:

1. Connect an AC frequency meter to the generator’s AC

power output leads.

2. Disconnect all electrical loads. This can be done by setting

the main circuit breaker to "Off“ or "Open".

3. See Figure 9. Turn the load adjustment as far as it will go

toward the "R" (maximum rich).

4. Start the engine, let it stabilize and warm up at no-load.

Page 6.2-1