Section 7.1- mechanical governor, General description, Governor maintenance – Generac 86640 User Manual

Page 74: Dc alternator removal, Governor lubrication, Engine governor adjustment

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 7.1- MECHANICAL GOVERNOR

General Description

The mechanical engine governor utilizes the principle of

spring tension versus centrifugal force to maintain a steady

state engine speed, regardless of the applied load. When

centrifugal flyweight force exceeds governor spring tension,

the flyweights act on a yoke to rotate a rocker shaft. Rocker

shaft rotation decreases carburetor throttle setting and en

gine speed decreases. As engine speed decreases, governor

spring tension becomes greater than flyweight centrifugal

force. The spring then increases carburetor throttle setting

and engine speed increases. The governed speed is that

rpm at which flyweight force and spring force are equal.

The governor flyweights are driven by an engine v-belt.

The pulley which drives the flyweights also dnves a DC

alternator assembly, used to maintain battery state of charge

during engine operation.

Figure 1. Mechanical Engine Governor

Governor Maintenance

Maintenance and repair of the governor is limited to the

following;

n Removal and replacement of the DC alternator assem-

bly.

□ Removal and replacement of governor lever, links and

springs.

D Removal, replacement and adjustment of governor to

carburetor linkage.

CH Adjustment of governed speed.

dC Alternator Removal

Refer to Figure 4 on next page. Remove the DC alterna

tor assembly as follows:

1. Remove hex jam nut (Item 43), wave washer (Item 48), and

pulley half (Item 44).

2. Remove the DC alternator Rotor (Item 44).

3. Remove socket head screws (Item 35) and lockwashers

(Item 22).

4. Remove the Stator (Item 47).

Reassemble the DC alternator in the reverse order of re

moval. Install socket head screws that retain the stator and

tighten them to 5 foot-pounds (7 N-m). Tighten the hex jam

nut to 35 foot-pounds (47 N-m).

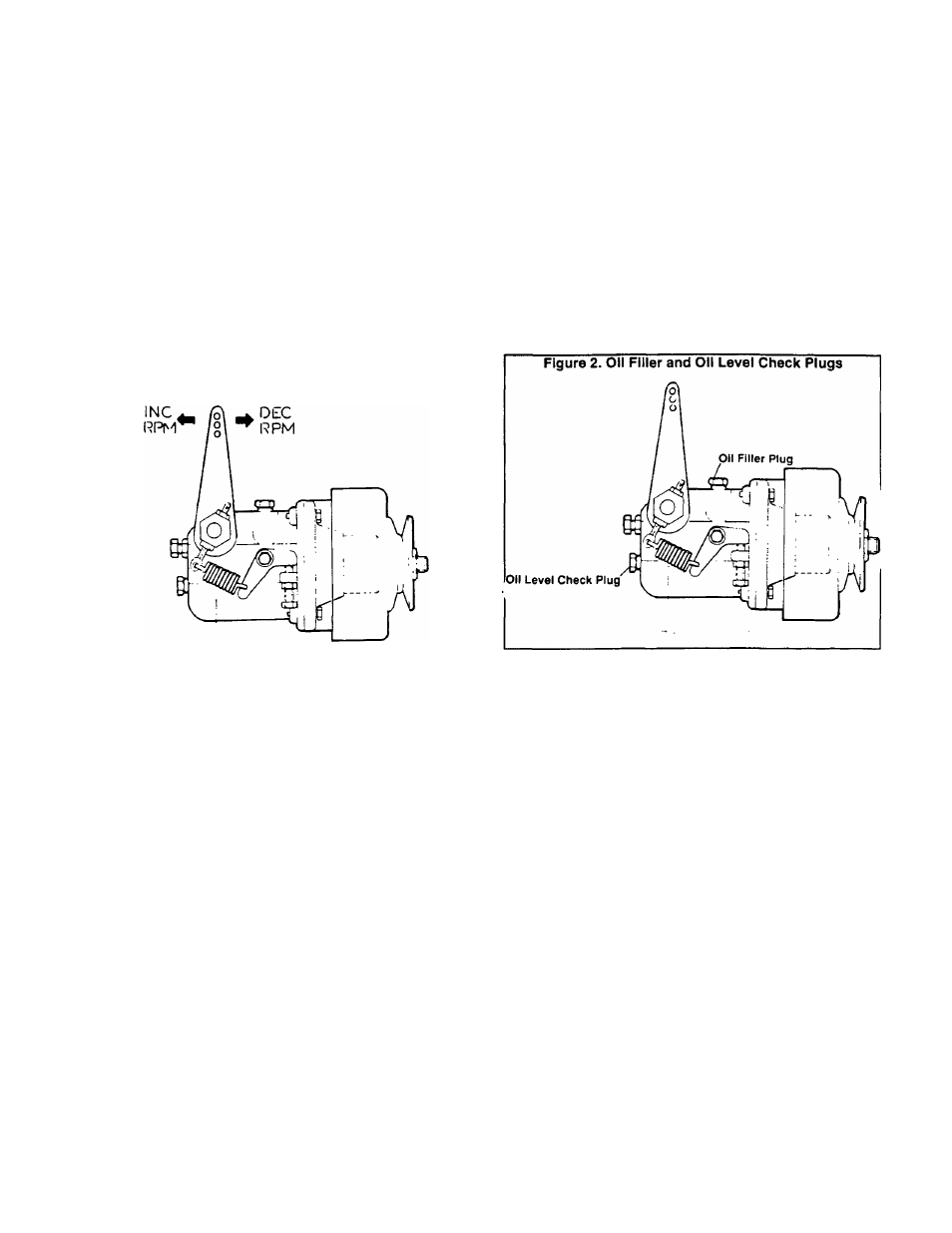

Governor Lubrication

See Figure 2. To fill the governor with oil, proceed as

follows:

1. Remove OIL FILLER PLUG and OIL LEVEL CHECK

PLUG,

2. Add engine oil through FILLER PLUG until oil just starts to

overflow the OIL LEVEL CHECK PLUG opening. Pour slowly.

3. When oil level is correct, install and tighten OIL FILLER

and OIL LEVEL CHECK PLUGS.

Engine Governor Adjustment

1. Connect an AC frequency meter across the generator’s AC

output leads.

2. Turn OFF all electrical loads. Initial adjustments will be

accomplished at no-load.

3. Start the engine, let it stabilize and warm up.

4. Check the no-load AC frequency. Readings should be as

follows:

Units Rated at 60 Hertz = 60.5-63.5 Hertz

Units Rated 50 Hertz = 49-51 Hertz

5. No-Load Governed Speed Adjustment: If adjustment of

no-load governed speed is required, proceed as follows (see

Figure 3):

a. Loosen the NO-LOAD BUMPER SCREW lock nut, then

loosen the NO-LOAD BUMPER SCREW so the governor

is not pre-loaded.

b. Adjust the NO-LOAD SPEED ADJUST SCREW to ob

tain a frequency reading as close as possible to 61.5 Hertz

for units rated 60 Hertz; or to 50.0 Hertz for units rated 50

Hertz.

c. Adjust the NO-LOAD BUMPER SCREW to obtain a

frequency of 62 Hertz (60 Hertz units); or 51 Hertz (50 hertz

units).

6. Adjustment Under Load: Apply an electrical load to the

generator equal to the rated wattage/amperage capacity of

the generator. Then, proceed as follows:

Page 7.1-1