Gas carburation, Lp gas conversion kit – Generac 86640 User Manual

Page 67

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

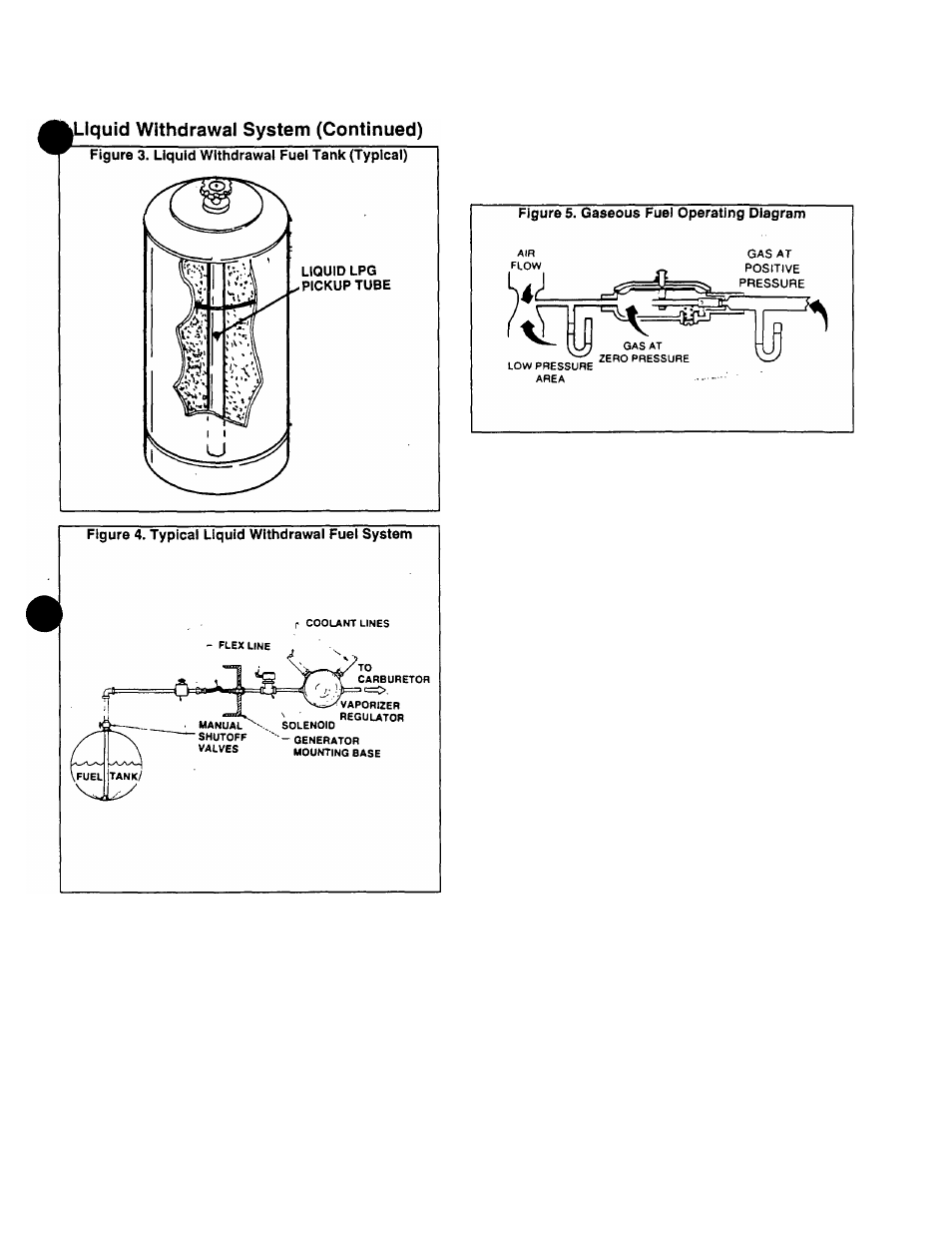

As the throttle is opened wider, air flow increases through

the carburetor venturi and the vacuum at the venturi throat

Increases proportionally. Diaphragm movement increases,

the regulator metering valve opens further, and gas flow to

the carburetor increases.

The following facts apply to venturi type gas carburetion

systems:

n The regulator must be properly adjusted so that it will

stop the flow of gas when the engine is not running.

D The slightest vacuum should lift the regulator metering

valve off its seat and allow gas flow to the engine.

D If diaphragm spring force is excessive, too much vacuum

will be needed to open the regulator metering valve. This

will result in a flat spot or sluggish progression off idle.

Lean mixtures and power loss at full loao may also result.

D If diaphragm spring force is too weak, fuel leakage after

shutdown may result. Hard starting and the danger of fire

exist.

DANGER:

GASEOUS

FUEL

REGULATORS

MUST

BE PROPERLY ADJUSTED AND TESTED AT THE

TIME

OF

INSTALLATION,

TO

PREVENT

GAS

LEAKAGE AND POSSIBLE FIRE OR EXPLOSION.

INSTALLATION,

ADJUSTMENT

AND

TESTING

SHOULD

BE

ACCOMPLISHED

ONLY

BY

QUALI

FIED

GAS

SERVICE

TECHNICIANS.

THE

GAS

FUEL

SYSTEM

MUST

COMPLY

WITH

ANSI

119.2/NFPA

501C,

CHAPTER

2,

“FUEL

SYSTEMS

AND

EQUIPMENT".

FOLLOWING

INSTALLATION

THE SYSTEM MUST BE PROPERLY PURGED AND

LEAK TESTED. NO LEAKAGE IS PERMISSIBLE.

Gas Carburation

See Figure 5. During the engine Intake stroke, air is

drawn into the engine. This air flows through a venturi in the

carburetor and creates a vacuum at the venturi throat. The

amount of vacuum created is proportional to the amount of

air flow. That is, the greater the air flow through the venturi,

the greater the amount of vacuum.

The vacuum created at the carburetor venturi throat acts

on a diaphragm in the vaporizer-regulator (liquid withdrawal

system) or pressure reducer valve (vapor withdrawal), to pull

the diaphragm toward the source of vacuum. Diaphragm

movement opens a metering valve and allows gas to flow to

the carburetor.

LP Gas Conversion Kit

An LP gas conversion kit is available for installation on

NP and IM generators with 1.2 liter gas engine. Installation of

thé proper conversion kit will allow LP gas to be used as a

fuel. The Model 9251 kit is a vapor withdrawal type; Model

9052 is a liquid withdrawal type. The kits do not include fuel

supply tanks, nor do they include fittings, lines, etc., required

to store the fuel and deliver the fuel to the fuel lockoff solenoid.

Instructions are included with the kit. To order instructions

only, specify manual Part No. 78360.

A primary regulator Is required for vapor withdrawal

systems. That regulator is not included in the kit.

Page 6.1-2