Cylinder head removal, Checking cylinder head distortion – Generac 86640 User Manual

Page 33

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 2.3- CYLINDER HEAD

Cylinder Head Removal

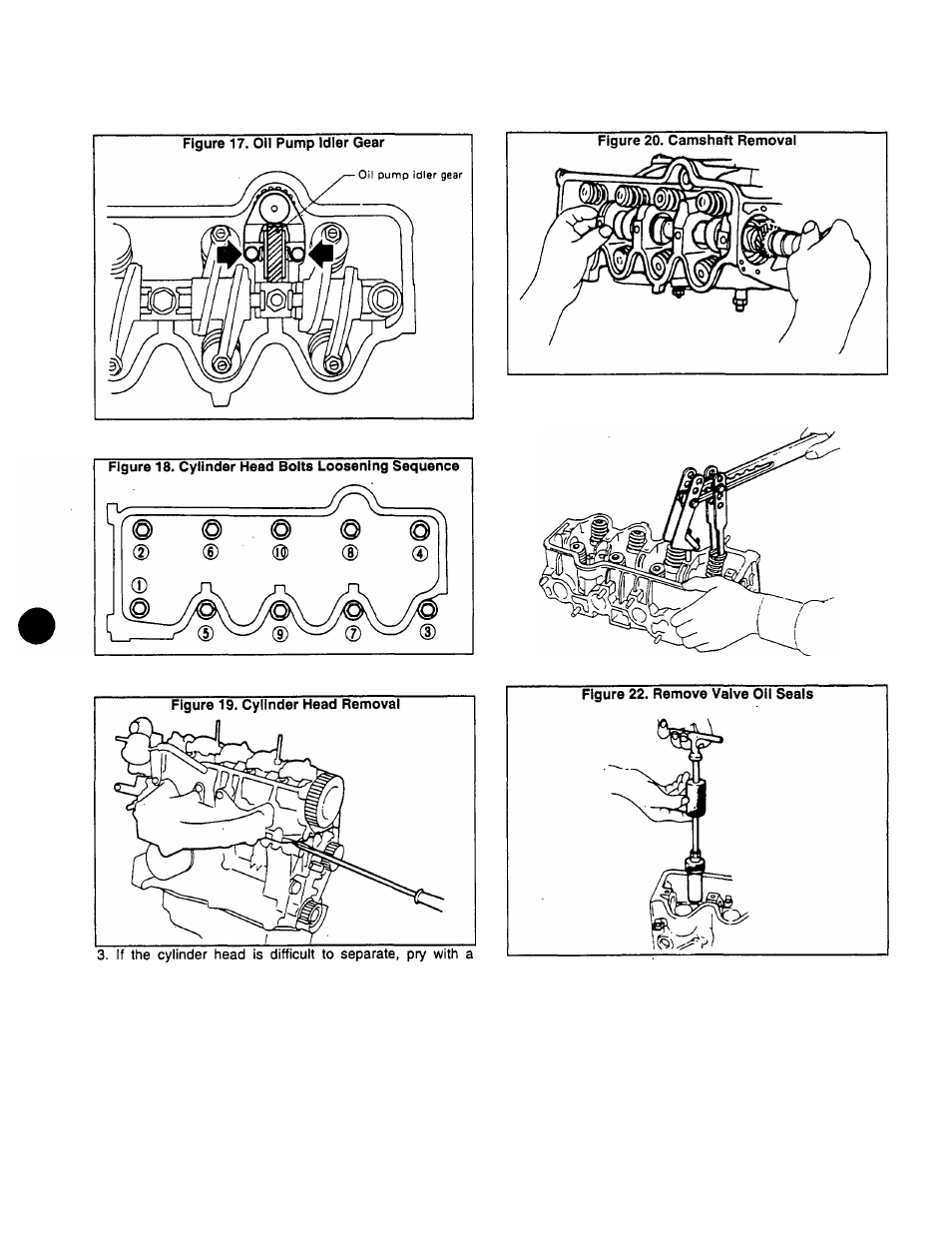

1. Remove timing belt (Section 2.2). Then, remove OIL PUMP

IDLER GEAR.

2. Remove the cylinder head. Loosen bolts in 2 or 3 stages,

in the sequence shown above.

screwdriver.

4. Remove the Camshaft (Figure 20).

5. Remove valve components parts (Figure 21).

6. Use a suitable puller to remove valve oil seals (Figure 22).

Checking Cylinder Head Distortion

Use a thickness gauge and a straightedge to measure

cylinder head distortion. See Figure 23 (next page). Lay the

Figure 21. Remove Valve Component Parts

straightedge across the cylinder head surface as shown.

Surface warpage must not exceed 0.004 inch (0.1 mm). If the

cylinder head exceeds the stated value, it must be replaced.

Resurfacing Limit: The amount of resurfacing that can be

done on the cylinder head depends on the amount of resur

facing on the cylinder block. If the amount of HEAD surfacing

is "A^and the amount of BLOCK surfacing is "B“, the maxi

mum limit is as follows:

Page 2.3-1