General, Vapor withdrawal system, Liquid withdrawai system – Generac 86640 User Manual

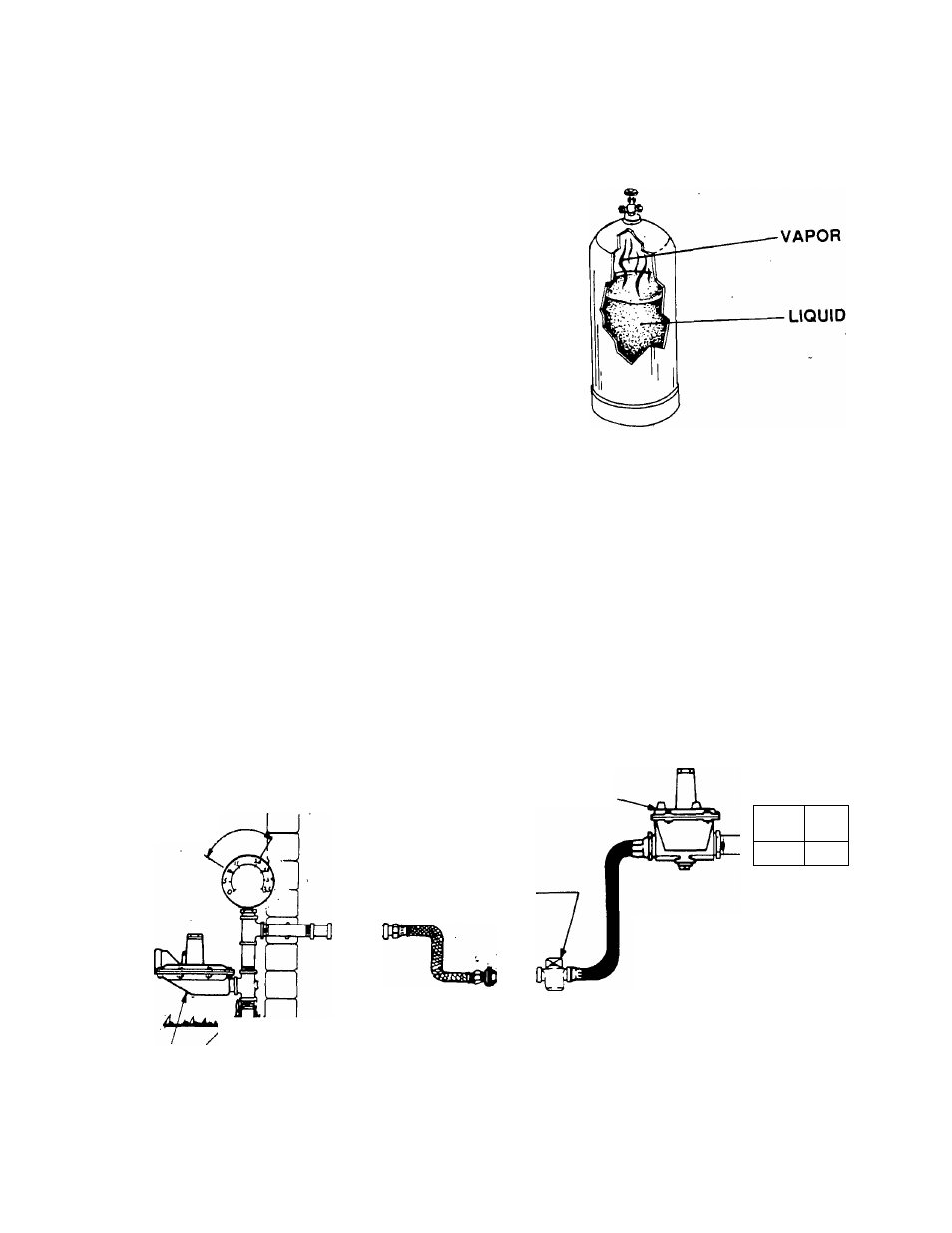

Page 66: Figure 2. a typical vapor withdrawal system

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 6.1- INTRO. TO GASEOUS FUEL SYSTEMS

General

Some NP/IM series engine-generators may be equif^ed

with optional LP (liquefied petroleum) gas fuel systems. This

fuel is supplied as a liquid in pressure tanks.

LP gas is usually made up of (a) propane, (b) butane, or

(c) a mixture of the two gases. The liquefied fuel must be

converted to its vapor state before it enters the engine carbu

retor. Propane will vaporize at temperatures as low as 20' F.

(-6.7‘ C.). Butane exists in its liquid state when temperatures

drop below 32' F. (O’ C.). In colder weather, fuel suppliers will

usually increase the amount of propane in the fuel mixture for

better vaporization. Under extremely cold conditions, butane

gas may not provide sufficient vapor pressure to operate the

engine.

Q One gallon of butane liquid equals about 31.26 cubic feet

of butane gas.

EH

One gallon of propane equals about 36.39 cubic feet of

propane gas.

Vapor Withdrawal System

The LP gas fuel system may be either (a) a vapor

withdrawal system or (b) a liquid withdrawal system.

The vapor withdrawal system utilizes the vapors that

form above the liquid fuel in the supply tank. One typical

vapor withdrawal supply tank is shown in Figure 1.

The vapor withdrawal system, because it uses qaseous

fuel vapors. Is much like a natural gas system. See Figure 2.

The fuel vapors are delivered to a customer-supplied primary

regulator which reduces the gas vapor pressure. The gas

then goes to a fuel lockoff solenoid. Optimum gaseous pres

sure at the inlet to the fuel lockoff solenoid is about 11 inches

(water column) and not to exceed 14 inches (water column).

The function of the primary regulator is to provide this opti

mum fuel pressure to the solenoid. From the fuel lockoff

solenoid, the gaseous fuel is delivered to the inlet of a

pressure reducer valve. The pressure reducervalve receives

the gas at the stated optimum pressure, reduces the gas

pressure to a negative (vacuum) pressure of about -1 inch

(water column). The gas is then delivered to the carburetor

which meters the gas to the engine based on engine demand.

Figure 1. Typical Vapor Withdrawal Supply Tank

Liquid Withdrawai System

A typical liquid withdrawal fuel supply tank is shown in

Figure 3 (next page). A pickup tube extends down into the

tank. Vapor pressure on top of the fuel in the tank forces the

fuel to flow through the pickup tube and to the engine-gener

ator fuel system.

A typical liquid withdrawal type fuel system is shown in

Figure 4 on the next page. From the fuel supply tank, liquid

fuel flows to a fuel lockoff solenoid on the generator. The

liquid fuel Is then delivered to a vaporizer-regulator. Heated

engine coolant also flows through the vaporizer-regulator, to

heat the fuel and change it to its vapor state. The vaporized

fuel is then delivered to the engine carburetor at greatly

reduced pressure.

Figure 2. A Typical Vapor Withdrawal System

SECONDARY REGULATOR

11 In. H20

OPTIMUM

FUEL SHUTOFF VALVE

' r

br

r CARBURETOR-

I

? FROM SUPPLY TANK

PRIMARY REGULATOR

Page 6.1-1