Removal, Disassembly, Reassembly – Generac 86640 User Manual

Page 63: Installation, Automatic choke adjustment

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 5.3- CARBURETOR

Removal

Remove carburetor air intake components as necessary

to gain access to the carburetor. Disconnect the carburetor-

governor link. Disconnect fuel line. Remove carburetor, car

buretor adapter and gaskets.

Disassembly

See Figure 5 on next page. Disassemble the carburetor

as follows:

1. Remove two screws and lockwashers, then remove FUEL

INLET PLATE and GASKET.

2. Remove two screws and washerts, then remove CHOKE

SOLENOID ASSY.

3. Remove four screws and washers, then remove FLOAT

BOWL COVER along with FLOAT BOWL GASKET, FLOAT,

FLOAT SHAFT, SPfflNG, FUEL VALVE AND SEAT ASSY.

4. Remove FLOAT SHAFT, SPRING, FUEL VALVE and

FLOAT.

5. Remove FLOAT BOWL GASKET.

6. Remove SEAT ASSY.

7. Remove two CHOKE PLATE SCREWS, then remove

CHOKE PLATE.

8. If necessary for replacement, remove FUEL SOLENOID

and seal.

9. Remove IDLE ADJUSTING NEEDLE & SPRING.

10. Clean all parts in clean gasoline.

Reassembly

Reassemble all parts in the reverse order of disassem

bly. During the reassembly process, install new parts from

carburetor repair kit. Pay close attention to the following:

D Open throttle plate slightly for idle speed.

D Set the Idle adjusting needle 3/4 turn open.

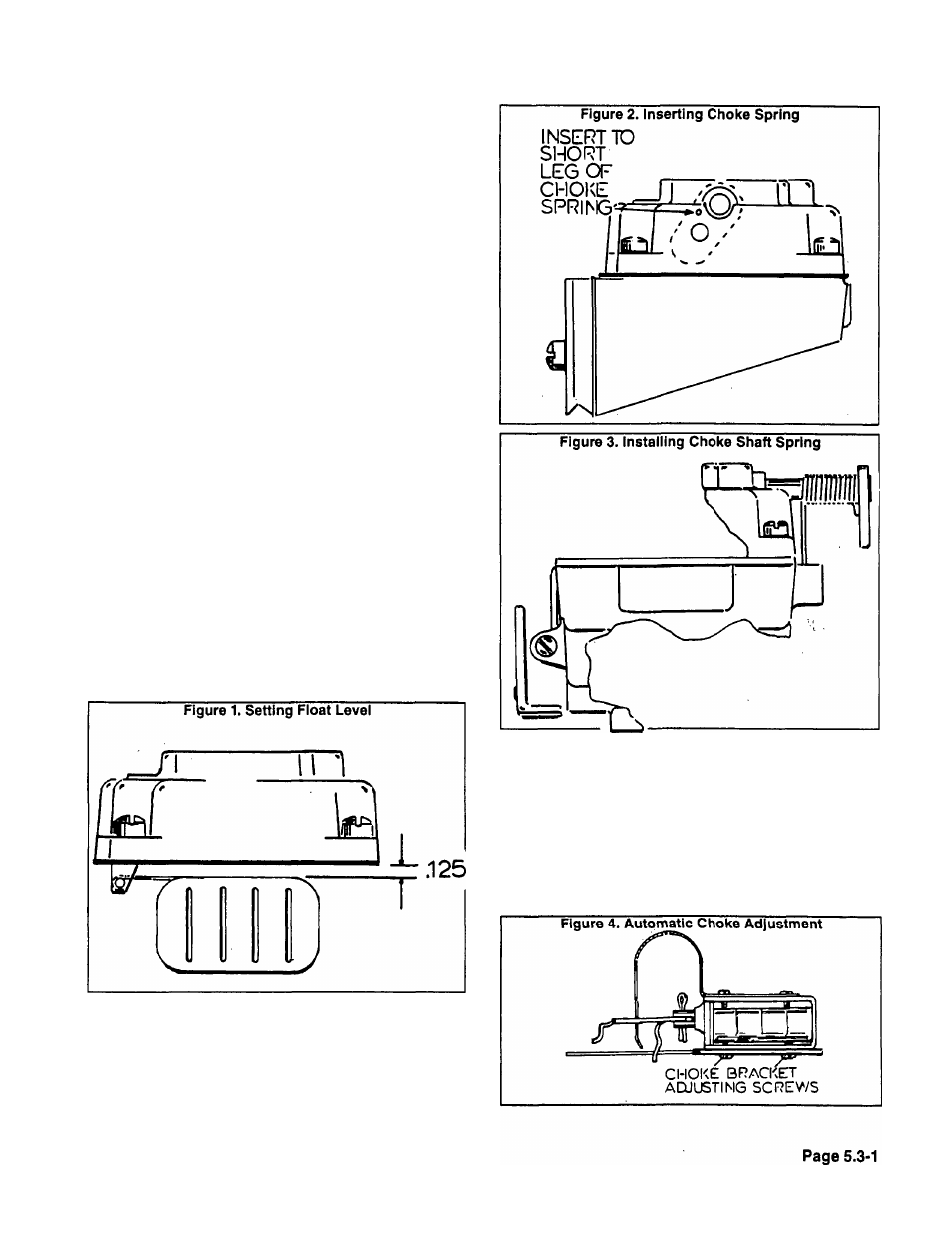

With float bowl cover inverted and float bowl gasket

installed, set float level 0.125 inch (3.175mm) from the float

bowl gasket (see Figure 1).

Tighten air intake mounting screws. Make sure the throt

tle shaft rotates freely. Tighten the FUEL SOLENOID to 70

inch-pounds.

Insert short leg of CHOKE SHAFT SPRING into small

hole in CHOKE SHAFT (Figure 2). Wind SPRING 1-1/2 turns

counterclockwise, anchor on retaining screw boss.

Installation

Install casket, adapter, gasket and carburetor. Retain

with socket head machine screws.

Automatic Choke Adjustment

Loosen CHOKE SOLENOID adjusting screws and adjust

choke position so that, with the solenoid pulled in (energized),

the choke piate is closed. With choke plate closed, tighten the

adjusting screws. Then, with solenoid extended, bend tip of

the bi-metal until choke plate is about 1/8 inch from vertical

and towards the closed position.