6 installer parameters – LAARS NeoTherm NTV1000 - Install and Operating Manual User Manual

Page 89

NeoTherm Boilers and Water Heaters

Page 85

9.6

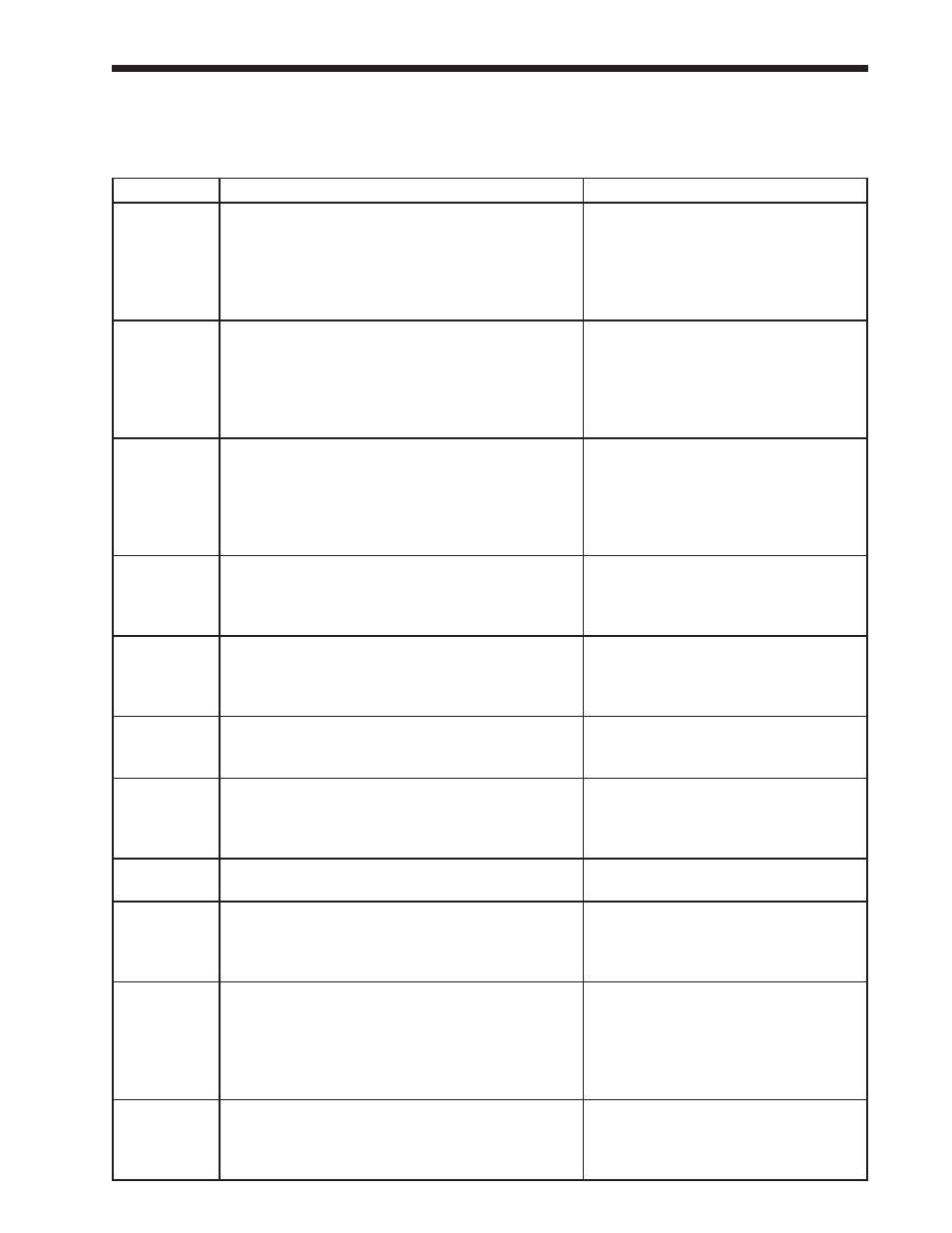

Installer Parameters

This is a list of all of the parameters which can be accessed using the Installer password.

Label

Description

How to Reach

4 mA water

temperature

If a 4 – 20 mA input is used to adjust the setpoint,

this entry sets the low limit of the control range.

(In the example shown here, an input of 4 mA

would result in a setpoint of 90°F.)

Home screen/ View Lead Lag/ Lead

Lag screen/ Lead Lag Master/ Lead

Lag Master screen/ Configure/ Lead

Lag Master Configuration screen/

Advanced Settings/ Central Heat

screen

20 mA water

temperature

If a 4 – 20 mA input is used to adjust the setpoint,

this entry sets the high limit of the control range.

(In the example shown here, an input of 20 mA

would result in a setpoint of 120°F.)

Home screen/ View Lead Lag/ Lead

Lag screen/ Lead Lag Master/ Lead

Lag Master screen/ Configure/ Lead

Lag Master Configuration screen/

Advanced Settings/ Central Heat

screen

Boiler pump

control

The Boiler pump (Pump A) can be turned on

manually, or it can be set to operate automatically.

If it is turned on, then it remains on until the

control is changed back to Auto. In Auto mode

it operates according to the demand and overrun

time.”

Home screen/ Select controller/ Status

Summary screen/ Configuration/ Pump

Configuration/ Left- or Right- arrow

buttons/ Boiler Pump screen/ Control

Settings button

Boiler pump

cycle count

Boiler pump cycle count. Can be written to a new

value (e.g. if the pump or controller is replaced).

Home screen/ Select controller/ Status

Summary screen/ Configure button/

Configuration List/ Select Statistics

Configuration line

Burner Cycle

Count

This is incremented on each entry to Run. It can

be written to a with a new value if the burner or

controller is replaced.

Home screen/ Select controller/ Status

Summary screen/ Configure button/

Configuration List/ Select Statistics

Configuration line

Burner Name This parameter allows the installer to give each

controller a unique name.

Home screen/ Select controller/ Status

Summary screen/ Configuration button/

System ID and Access

Burner Run

Time

This measures the time spent in the Run state. It

can be written to with a new value if the burner or

controller is replaced.

Home screen/ Select controller/ Status

Summary screen/ Configure button/

Configuration List/ Select Statistics

Configuration line

Burner

Switch

This parameter enables or disables the burner

control. When it is off, the burner will not fire.

Home screen/ Select controller/ Status

Summary screen

CH (Central

Heat) D gain

This gain is applied to the Differential term of the

PID equation for the CH loop.

Home screen/ Select controller/ Status

Summary screen/ Configuration button/

Central Heat Configuration/ Arrow

keys/ Modulation screen

CH (Central

Heat) Enable

This parameter determines whether the Central

Heat loop is enabled or disabled. When it is

disabled, heat demand caused by the input

assigned to the CH loop is ignored. It may be

disabled to turn it off temporarily, or because the

application does not use this feature.

Home screen/ Select controller/ Status

Summary screen/ Configuration button/

Central Heat Configuration/ Arrow

keys/ Central Heat screen

CH (Central

Heat) Frost

Protection

Enable

The CH frost protection feature can be enabled to

run a pump (or pumps) and possibly fire the burner

whenever the CH input sensor is too cold.

Home screen/ Select controller/ Status

Summary screen/ Configuration button/

Anti-Condensation Configuration/