LAARS Heat Exchanger - Installation Manual User Manual

Heat exchanger replacement

Accessories & Parts

Document 4043H

Heat Exchanger Replacement

Gas-Fired Hydronic Boilers, Volume Water and Pool Heaters

Sizes 175,000 - 5,000,000 BTU/hr.

AJ, AL, AQ 500-1666

AP 500-1825

For Models:

LC 154-3000

LJ, LL, LQ 500-4000

HK, LK 250-400

HB, LCR 154-560

VW, HH 500-1825

VW, HH 2000-5000

AF 420-3000

AL 1866-4000

AP 2200-4000

AP 2000-5000

BARRIER

SPECIAL BYPASS ASSEMBLY

PUMP DISCHARGE BAFFLE

NJ, NL, NQ 500-1666

PW, PH 500-1825

SJ, SL, SQ 500-1666

IW 500-1825

HB, LCR 630-3000

HJ, HL, HQ 500-4000

LJ, LL, LQ 500-4000

VW, HH 2000-5000

SK 250-400

SC 560-3000

PUMP DISCHARGE BAFFLE

RJ, RL, RQ 500-1666

MJ, ML, MQ 500-1666

with rear mounted pump

RB 560-1190

RJ, RL 500-1666

MJ, ML 500-1666

MK 250-400

BARRIER WITH HOLE

BARRIER

SUCTION DIFFUSER

PUMP DISCHARGE BAFFLE

(in pump adapter)

SUCTION DIFFUSER

PUMP DISCHARGE BAFFLE

(in pump adapter)

SUCTION DIFFUSER

PUMP DISCHARGE BAFFLE

(in pump adapter)

NC 154-3000

NK 250-400

BARRIER

To Remove Heat Exchanger:

1. Turn off all electrical power to the heater.

2. Disconnect the water piping from the header.

3. Remove the vent, draft diverter, and flue extension.

4. Remove the jacket top, which is secured with sheet metal

screws.

5. Withdraw the flue collector, which is held in place with

cement or metal

screws.

6. Remove the sheet

metal strips, if

present on your

model, across the

ends of the heater

above the headers.

7. Remove the capillary

tubing going to the

thermostat bulb and

high limit switch bulb.

If the heat exchanger

is to be reversed, the existing tubing will have to be replaced

with longer tubing.

8. On heaters equipped with a mounted pump on the side of the

jacket, remove the screws holding the bracket. Maintain the

pump, bracket, and heat exchanger as one unit. Disconnect

all electrical wiring.

9. Remove the front and rear tile covers.

Lift out the heat exchanger. It may have to be jiggled carefully

to break the furnace cement seal.

To Reinstall the Heat Exchanger:

1. Coat the upper surfaces of the side tiles with furnace cement

before carefully lowering the heat exchanger into place.

2. Verify that all of the "V" and "T" baffles are properly installed

between the heat exchanger tubes. Also, be sure end refrac-

tory tiles fit inside of the casting ribs and seal on the flat part

of the casting.

3. Replace the front and rear tile covers.

4. Repeat steps 1 through 8 of the removal procedure in reverse

order to complete the installation.

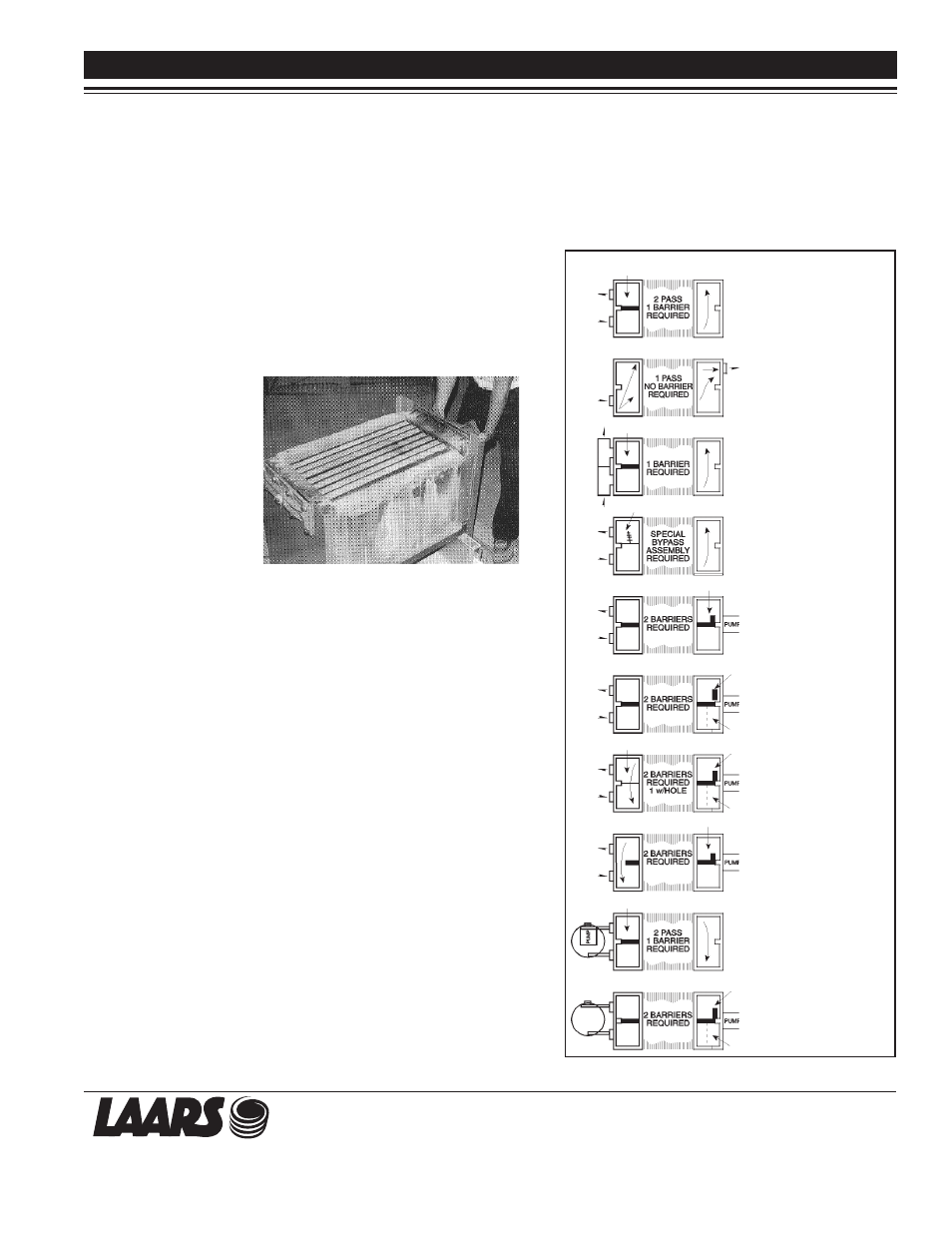

Water Barrier Position

Water barrier must be installed as shown in diagrams at right or

warranty is void. The diverter plate must be reinstalled between

the tub and header cover on the inlet side of the heat exchanger.

When replacing a heat exchanger, the water barrier must

be installed to ensure a proper fit with the replacement heat

exchanger. Water barrier p/n for I/E 500-1825 and Q boilers

500-1666 is 20230101. Water barrier p/n for LB 2000-5000 is

20230100.

A subsidiary of

Corporation

BRADFORD WHITE

Heating Systems Company

H0062400H

800.900.9276 • Fax 800.559.1583 (Customer Service, Service Advisors)

20 Industrial Way, Rochester, NH 03867 • 603.335.6300 • Fax 603.335.3355

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com

Litho in U.S.A. © Laars Heating Systems 0806 Document 4043H