Job h - connect the modbus wiring, Laars heating systems, Mb1 mb2 – LAARS NeoTherm NTV1000 - Install and Operating Manual User Manual

Page 70: Display

LAARS Heating Systems

Page 66

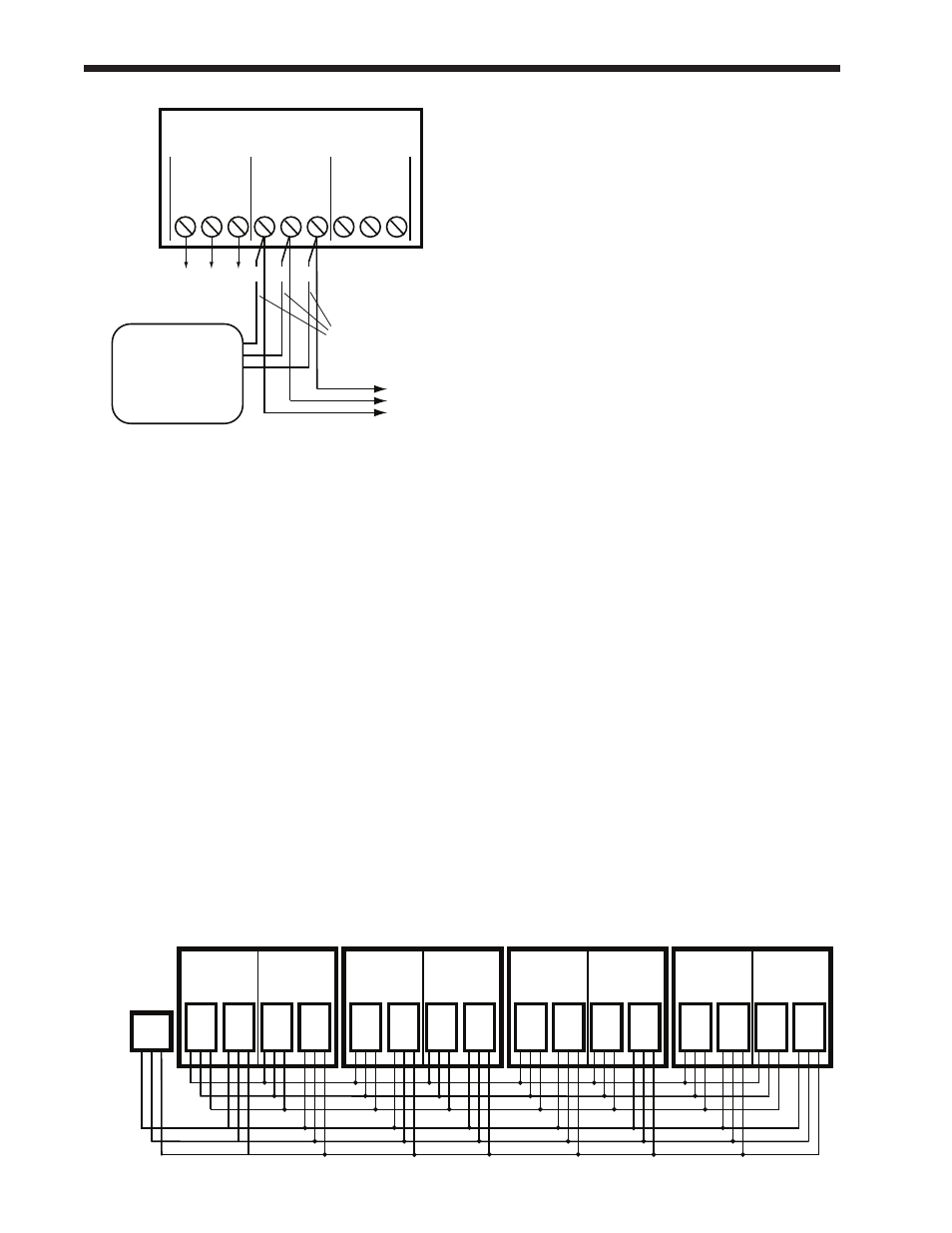

fig. 81 – modbus Connections

Boiler 1

Ctrl

1

Ctrl

2

A B C

MB 2

MB 1

MB 2

MB 1

A B C

Boiler 2

Ctrl

1

Ctrl

2

A B C

MB 2

MB 1

MB 2

MB 1

A B C

Boiler 3

Ctrl

1

Ctrl

2

A B C

MB 2

MB 1

MB 2

MB 1

A B C

Boiler 4

Ctrl

1

Ctrl

2

A B C

MB 2

MB 1

MB 2

MB 1

A B C

A B C

A B C

A B C

A B C

A B C

A B C

A B C

A B C

A B C

Display

9

8

7

6

5

4

3

2

1

B

A

C

B

A

C

B

A

C

MB1

MB2

R1

Display

MB1 connections -

Do not change

Disconnect

the wires from

MB2 to the

display

fig. 80 – Disconnecting an Unused operator

Interface

Job H - Connect the modbus Wiring

(This is an individual function – do this on each of the controls.)

In an installation with multiple boilers, the controllers

are arranged in a “daisy chain.” The wiring from

the Secondary controller on one boiler runs to the

Primary controller on the next boiler. Use 22 AWG

or thicker shielded twisted pair wire with drain. Two

twisted pairs or three conductors are needed.

note – The Modbus wiring should be done last. The

controllers must be set up and addressed correctly

before the wiring is complete. If the wiring is attached

before the Modbus addresses for the controllers are

set up, there might be multiple controls with the same

address, and the system will not work.

1. Connect the wiring from the Secondary

controller on Boiler 1 to the Primary controller

on Boiler 2. Connect three wires from the

Modbus 1 terminal (MB1 on J3) on the

Secondary control on Boiler 1 to MB1 (also

MB1 on J3) on the Primary control on Boiler 2.

Wire A on Boiler 1 must be connected to A on

Boiler 2, wire B on Boiler 1 goes to B on Boiler

2, and wire C on Boiler 1 goes to C on Boiler 2.

2. Repeat this wiring from Boiler 2 to Boiler

3, and from Boiler 3 to Boiler 4 if additional

boilers are included. A maximum of 4 boilers or

8 controls can be connected this way.

3. Another part of the “daisy chain” connection

uses the MB2 connectors. Connect three wires

from the Modbus 2 terminal (MB2 on J3) on

the Secondary control on Boiler 1 to MB2 (also

MB2 on J3) on the Primary control on Boiler

2. Be sure that wire A on Boiler 1 goes to A on

Boiler 2, wire B on Boiler 1 goes to B on Boiler

2, and wire C on Boiler 1 goes to C on Boiler 2.

4. Repeat this wiring from Boiler 2 to Boiler

3, and from Boiler 3 to Boiler 4 if additional

boilers are included.

5. Connect the drain wire from each twisted pair

wire to ground on one end of each wire only.

Job I – Set the Parameters Used by the

lead/lag System

(This is a Lead/Lag function – do this once for the whole Lead/

Lag system. Use the controller set up as the Lead/Lag Master –

usually the Primary controller on Boiler 1.)

We have already explained how the Lead/Lag Master

controls the operation of the Lead/Lag system. Your

job at this point is to enter the control values that the

Lead/Lag system will use.