6b.3 cold water make-up, 6b.4 freeze protection, 6b.5 suggested piping schematics – LAARS NeoTherm NTV1000 - Install and Operating Manual User Manual

Page 30: 6b.6 suggested pumps, Laars heating systems, 6b.3 ntv cold water make-up, 6b.4 ntv freeze protection, 6b.5 ntv suggested piping schematics, 6b.6 ntv suggested pumps

LAARS Heating Systems

Page 26

6B.3 ntV Cold Water make-Up

The cold water make-up may be connected to the

tank or to the inlet of the boiler as shown in Figures

16-18. Install back flow preventers and shut offs

where needed or required by code.

6B.4 ntV freeze Protection

The NTV unit must never be installed outdoors

in a location which may experience freezing

temperatures. If installed indoors, and there is an

event such as a power outage, component failure or

other issue when freezing is likely, the heater and

system must be drained to avoid the risk of damage

due to freezing. Glycol must NOT be used in

volume water heating applications.

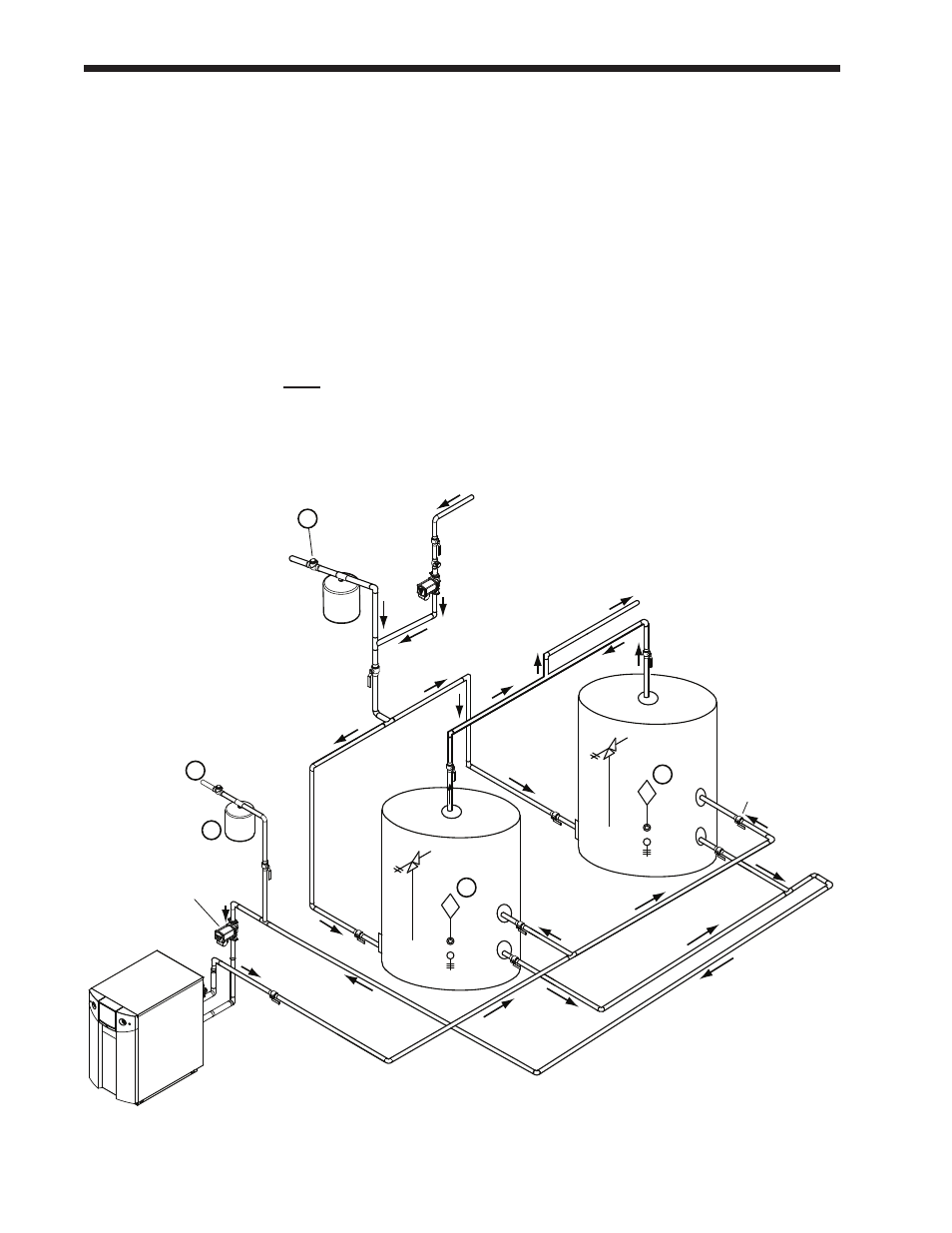

fig. 17 - DHW Piping - one Heater, two Vertical tanks

6B.5 ntV Suggested Piping

Schematics

Figures 16-18 show suggested piping

configurations for NTV boilers. These diagrams

are only meant as guides. All components or

piping required by local code must be installed.

6B.6 ntV Suggested Pumps

See Table 8 for water flow and head

requirements.

noteS:

1. Optional CWMU & recirculation line location.

2. Locate the NTV DHW sensor or remote aquastat well

in lower 1/3 of tank.

3. Back flow preventer may be required - check local

codes.

4. Thermal expansion tank may be required -

check local codes.

5.

Caution: Pump sizing must be based upon water

hardness at job site.

Cold water

supply

3

Expansion

tank

1

4

Pump

TPRV

2

Building

return

Ball valve

(typical)

TPRV

2

Supply

WarnInG: This drawing shows

suggested piping configuration and

valving. Check with local codes and

ordinances for additional requirements.