1 general information, 1 introduction, 2 about the neotherm control system – LAARS NeoTherm NTV1000 - Install and Operating Manual User Manual

Page 5

NeoTherm Boilers and Water Heaters

Page 1

Section 1

General InformatIon

WarnInG

NeoTherm units

must be installed in accordance

with the procedures detailed in this manual, or the

LAARS Heating Systems warranty will be voided.

The installation must conform to the requirements

of the local jurisdiction having authority, and,

in the United States, to the latest edition of the

National Fuel Gas Code, ANSI Z223.1/NFPA54.

In Canada, the installation must conform to the

latest edition of CSA B149.1 Natural Gas and

Propane Gas Installation Code, and/or local

codes. Where required by the authority having

jurisdiction, the installation of NeoTherm boilers

must conform to the Standard for Controls and

Safety Devices for Automatically Fired Boilers,

ANSI/ASME CSD-1. Any modifications to the

boiler, its gas controls, or wiring may void the

warranty. If field conditions require modifications,

consult the factory representative before initiating

such modifications.

1.1 Introduction

This manual includes information which will help

you to install, operate, and maintain the NeoTherm

1000 system. Please read this manual completely

before proceeding with the installation. If you have

any questions regarding this equipment, please

consult the LAARS Heating Systems factory, or

a local factory representative. Many operating

problems are caused by improper installation.

1.2

about the neotherm Control

System

This unit includes an advanced control system

which can perform many functions. This is part

of the reason why the NeoTherm 1000 can deliver

such outstanding performance. There are several

“branches” in the control software, and many

different display screens. For clarity, throughout

this manual we have made a special effort to show

you how to reach each of the important setup and

operating functions. We have done this in two ways:

•

In many cases, we have shown you the actual

screen display you will see while performing a

function.

•

Sometimes, instead of showing the screens, we

have just listed the series of choices you should

make in order to reach the section you want.

The arrangement of the control software is actually

quite logical, and after you have worked with it a bit,

you will not have any problems “finding your way

around.” We just want to give you some help with

the first part of the process, when you are “getting

used to” the control system.

Later in this manual, we will detail information on

the setup and operating procedures. There are a

couple of concepts you will need to understand right

from the start.

•

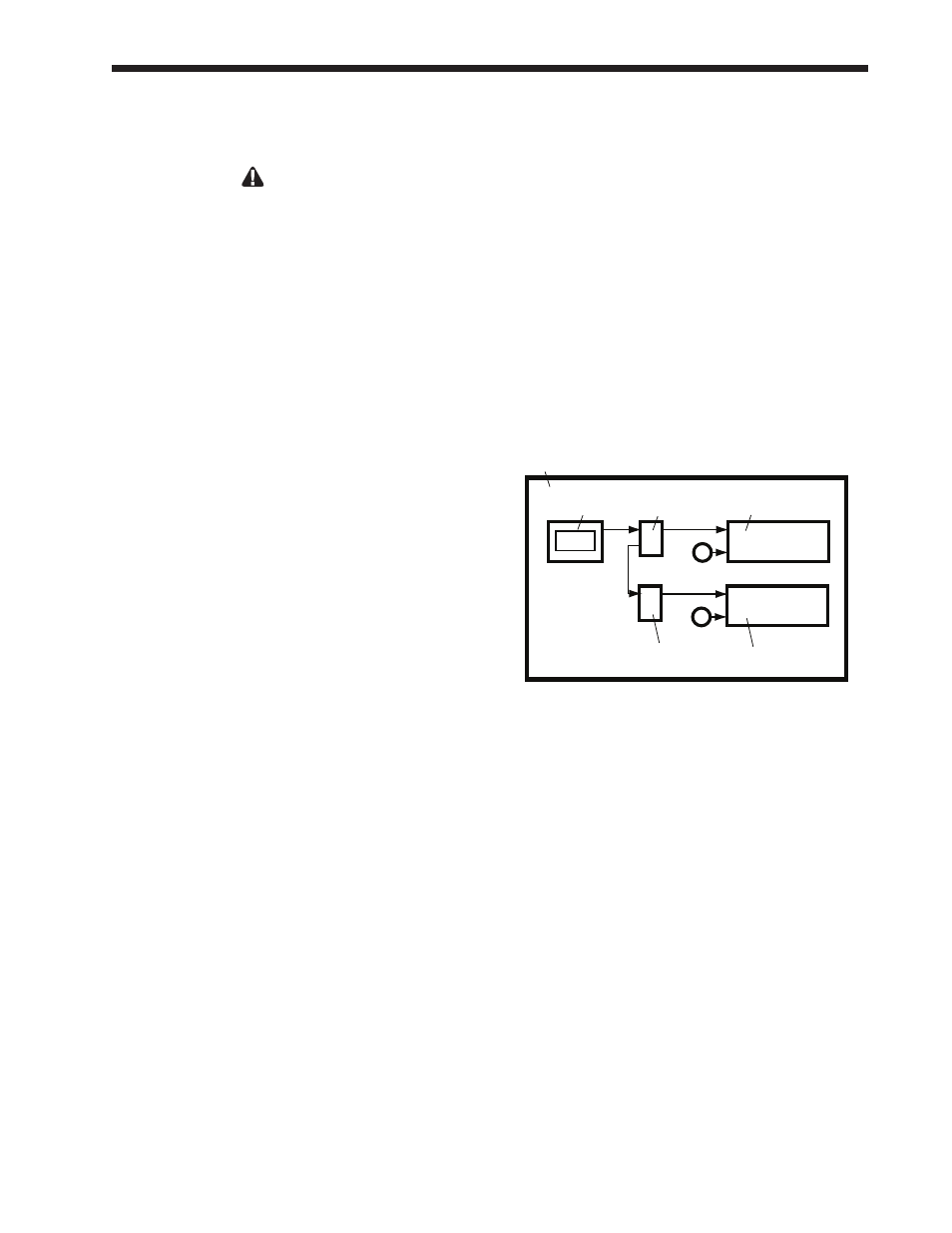

Each boiler has two controllers and two

burners, as shown in Fig. 1. A single Operator

Interface is used to communicate with both

controllers.

Primary

burner

Primary

controller

Gas

valve

Gas

valve

Secondary

controller

Secondary

burner

Operator

interface

Boiler 1

fig. 1 – Control arrangement in a Single-Boiler

Installation

Each controller and burner work together. Each

boiler includes two of these controller/burner

combinations.

Notice the different terms we are using here.

The term boiler refers to the whole unit –

the complete NeoTherm 1000. Each boiler

includes two separate controller/burner pairs.

•

NeoTherm 1000 units are always set up for

“Lead/Lag” operation. The term “Lead/Lag”

means that, as the heating load increases, the

control system brings additional burners on

automatically.

On a multiple-boiler installation, each of the

individual boilers is still set up as shown in Fig.

1 above. The controller/burner pairs on all of the

boilers are arranged in a “daisy chain.” Up to four

boilers, with up to eight controller/burner pairs, can

be connected in this way. See Fig. 2.