12 troubleshooting, 1 potential setup and synchronization problems – LAARS NeoTherm NTV1000 - Install and Operating Manual User Manual

Page 102

LAARS Heating Systems

Page 98

Section 12

troUBleSHootInG

12.1 Potential Setup and

Synchronization Problems

Because the NeoTherm 1000 uses a sophisticated

control system, it can constantly perform a series

of self-checks. For example, as a burner is lighted,

the controller checks each stage of the purge and

ignition process. If part of the process does not

happen on time, or takes too long to occur, the

controller stops the process. We have detailed these

self-checks in the section on “Operating Sequence.”

Two of these self-checks are particularly important:

• Controller synchronization

• Flap valve status

If the control system is not satisfied with the results

of both of these checks, it will not allow the system

to run. Sometimes the reason for this may not be

obvious at first – that’s why we are describing them

at the start of this section on Troubleshooting.

Operator

interface

Boiler 1

Slave 4

Boiler 2

Slave 3

Slave 2

Lead Lag

Master and

Slave 1

Slave 6

Boiler 3

Slave 5

Slave 8

Boiler 4

Slave 7

Addr

1

Addr

2

Addr

3

Addr

4

Addr

5

Addr

6

Addr

7

Addr

8

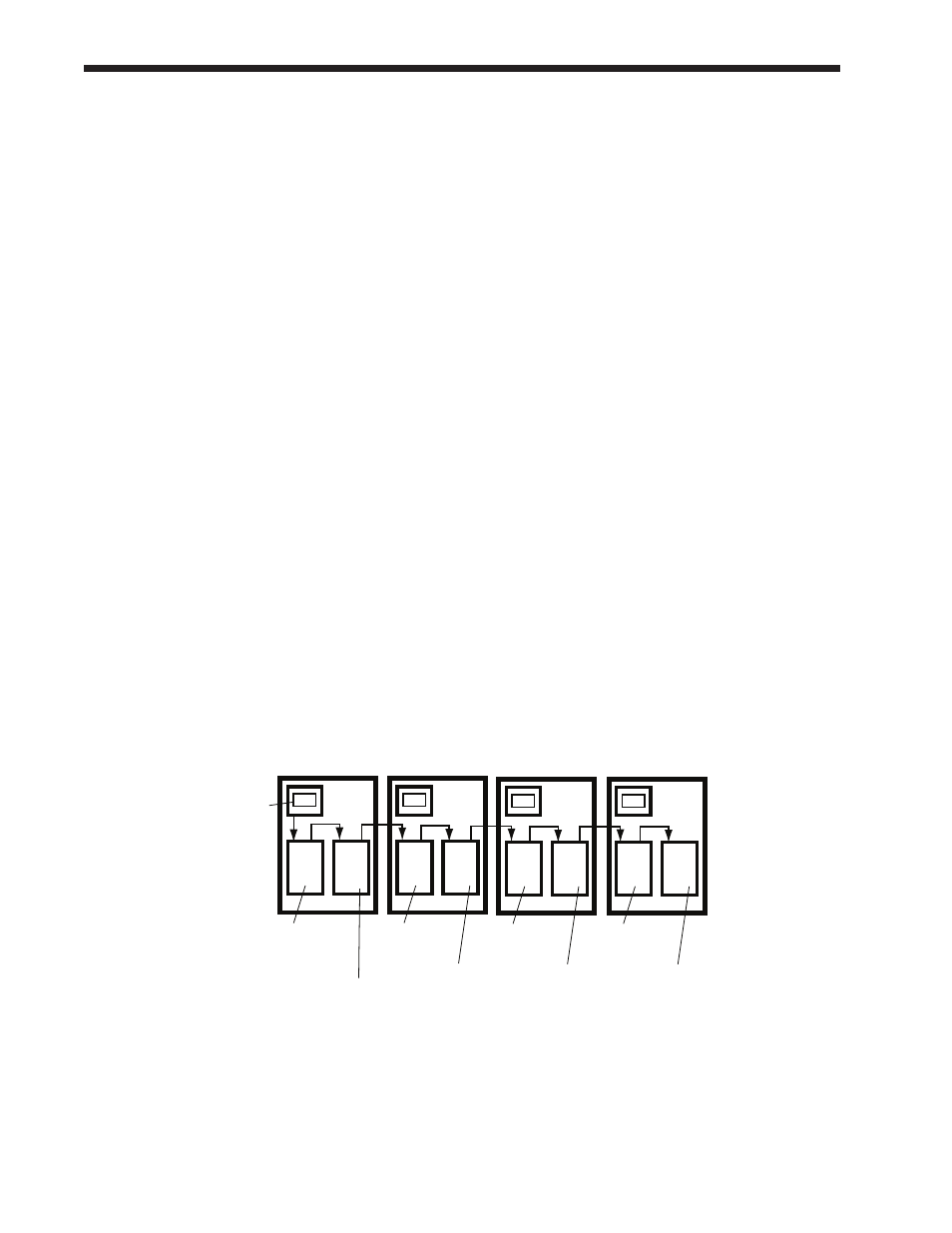

fig. 123 – lead/lag arrangement in a multiple-Boiler Installation

12.1.1 Controller Synchronization

On a multiple-boiler installation, the individual

boiler controllers are arranged in a “daisy chain”

using a Modbus connection, with the Secondary

control of one boiler connected to the Primary

control of the next boiler. Up to four boilers, with

up to eight controllers, can be connected in this way.

See Fig. 123.

As part of the setup process, each of these

controllers must be given a unique address. (For

details, see Section 9 - Installation and Setup.” The

controls must be set up and addressed correctly

before the Modbus wiring is completed. If the wiring

is attached before the Modbus control addresses are

changed, there will be multiple controls with the

same address, and the system will not work.

When a Lead/Lag system is first powered up, the

controller acting as the Lead/Lag Master goes

through a “synchronization” process. During

synchronization, the controller establishes

communications with each of the Slave controllers

via the Modbus link. The Slave controllers

download some setup parameters and operating

history information. (On a system with several

boilers, this phase can take several minutes.) If the

Master cannot establish communications with one of

the Slaves, it triggers a Hold or Lockout.