Temporarily install hinges and torque rods – Great Planes F-14 60 Kit - GPMA0435 User Manual

Page 9

D D 5. Using a sanding block and coarse (50 or 80-

grit) sandpaper, sand both sides of the elevator to a taper

(see cross-section on plans). The trailing edge should

end up approximately 3/32" wide. (Do not sand to a

sharp edge). Leave the ends square. Sand the leading

edge of the elevator to a "V-shape" as shown on the

plan.

D D 6. Sand the tip and front edges of the stab to a

rounded shape (see cross-section on plans). Sand the

trailing edge of the stab tip to the same taper as the

elevator.

D D 7. Draw a line parallel with the trailing edge of

the stab and 1/4" in front of it. Draw another line

parallel with the root edge of the stab and 1" out from it.

Cut out a clearance notch for the torque rods just as you

did on the fins earlier.

D 8. Go back to step 2 and build another stab and

elevator.

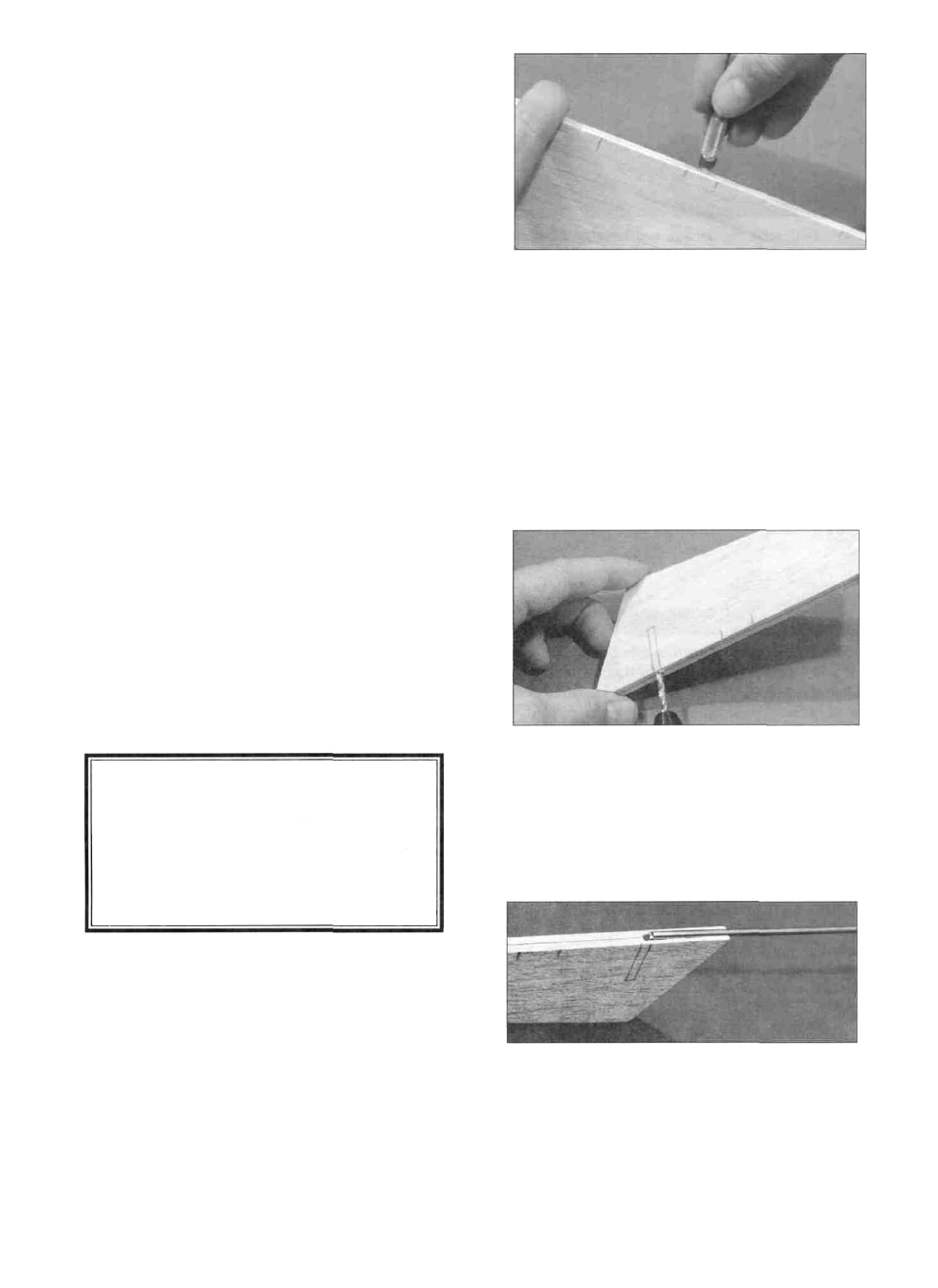

B. Make three or four more cuts in the same line, going

slightly deeper each time. As you make these

additional cuts. work on going straight into the wood.

Continue this process while "wiggling" the knife

handle forward and backward u n t i l the blade has

reached the proper depth for the hinge.

C. Trial fit the hinge into the slot. If the hinge is

difficult to push in. re-insert the knife and move it

back and forth in the slot a few times to enlarge the

slot. Do not glue the hinges yet.

TEMPORARILY INSTALL HINGES

AND TORQUE RODS

D 1. Using the plans as a guide, mark the hinge

locations on the stabs, elevators, fins and rudders. Also

designate one of each surface as being "right" and the

others as "left."

CAUTION!!! You must use extreme care when

cutting hinge slots with an X-acto knife, to

avoid cutting yourself! If the balsa part breaks

while you are pushing on the knife, the blade

could go into your hand before you know it! A

good precaution is to wear leather gloves while

performing the following steps.

D 2. Cut the hinge slots on the centerlines you drew

earlier. Our recommended hinge slotting method is

described below.

A. Begin by carefully cutting a very shallow slit at the

hinge location. The first cut is to establish your cut in

the right place, so concentrate on staying on the line

and don't cut too deep.

D 3. Check the plans and mark the location of the

torque rods on the rudders and elevators. Drill 7/64"

holes in the rudders and elevators (the holes are drilled

slightly oversize to allow for positioning, and to create a

hard epoxy "sleeve" around the wire). Groove the rudder

and elevator LE to accept the torque rod wires and nylon

bearings (See below).

HINT: Using an X-acto knife, sharpen the inside of one

end of a 1/8" diameter brass tube. and use it to cut the

groove in the leading edge of the rudders and elevators.

9