Great Planes F-14 60 Kit - GPMA0435 User Manual

Page 30

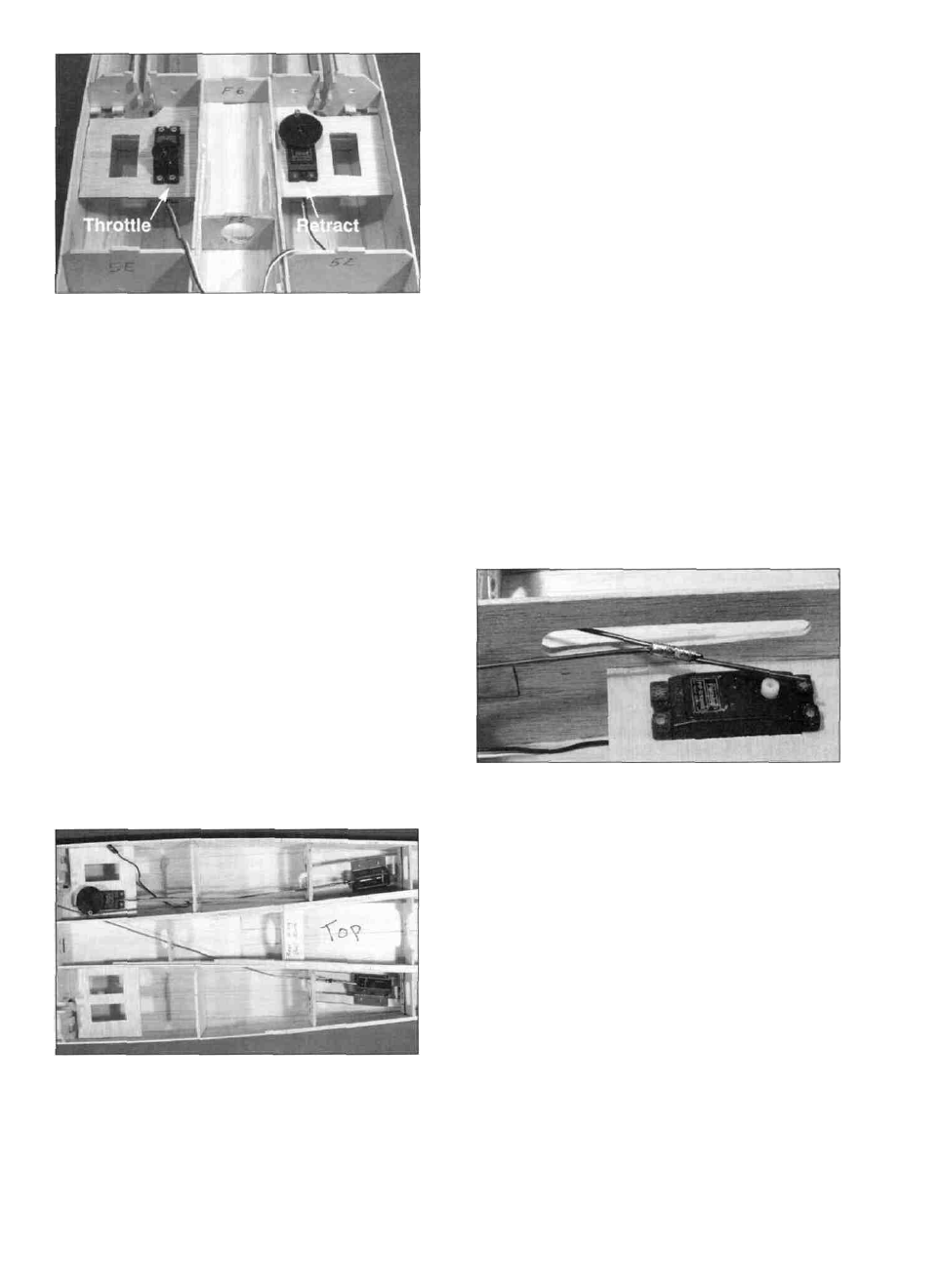

D 2. Punch out the two die-cut 1/8" ply rear servo

trays (F146F32) and test fit your servos to make sure

they fit. You will normally have to enlarge the opening

for the retract servo. Test fit the trays in place. Refer to

the plans to see how they are positioned and sand them if

needed to get them to fit. Tack glue the rear servo trays

in place approx. 1/2" below the lightening hole in the

inner turbine side. Put your servos in place and check to

see that the servo arms are positioned just below the

middle of the lightening hole. Adjust the servo trays if

necessary and securely glue them in place. If you are not

installing retracts, skip ahead to step 10.

so they don't flex during operation. Install an E-Z

connector approximately 9/16" from the center on a large

servo arm. Put the retract servo in place with the servo

arm on it to get an idea where the three pushrods must

meet. Use a 2-56 steel clevis on the retract end of each.

NOTE: There are a couple of places in the construction

sequence where you are required to solder certain metal

parts together. When you find it necessary to solder, use

the following procedure:

A. R o u g h e n the area to be soldered w i t h fine

sandpaper, then thoroughly clean the items to be

soldered with alcohol or degreasing solvent.

B. Assemble the items to be soldered.

C. Apply a small dab of soldering flux.

D. Heat the metal with a soldering gun or iron, and

apply solder to the metal. The metal must get

hot enough to melt the solder, and the solder

must freely flow into the joint.

E. Do not move the parts until the solder has

cooled.

F. Clean off the excess flux with alcohol or solvent.

G. Test the joint by pulling hard.

RETRACT PUSHRODS

D 3. Route the nose retract pushrod first. Try to run

it in a straight line from the servo, through F-2 and along

the fuse side up to the fuel tank floor. The retract

pushrods are not included in the kit. We used a Sullivan

red pushrod outer tube as a guide tube and a steel rod

with yellow pushrod spacers (see step 12 on page 32) on

it for the nose gear. Do not cut the pushrod to length yet.

D 4. Route the main gear pushrods as shown in the

photo. Due to the short distance here, we just used steel

pushrod wires without guide tubes. This will work fine

if you keep them running in as straight a line as possible

D 5. The two main gear pushrods need to be joined as

shown in the photo. Bend the two rods so they come

together parallel with each other and cut one off 3/4"

after they join. Wrap the two rods with soft bare copper

wire and actuate the retracts to make sure they both

operate together w i t h o u t the rods binding. When

satisfied with the fit, flow solder into the copper wire to

hold the two together (acid core solder works best for

this). This whole process is a "trial and error" type task

that takes some patience. If the rods get bent more than

necessary during the fitting process, just use them as a

pattern to make new rods with the correct bends. You

want to get this right now because it is tough to correct

after the fuselage is closed up.

D 6. Remove the main gear pushrods and slide a Du-

Bro #103 Strip Aileron Horn and wheel collar onto the

pushrod that runs on the same side as the nose gear rod.

Replace the main gear pushrods and position the aileron

30