Final assembly – Great Planes F-14 60 Kit - GPMA0435 User Manual

Page 42

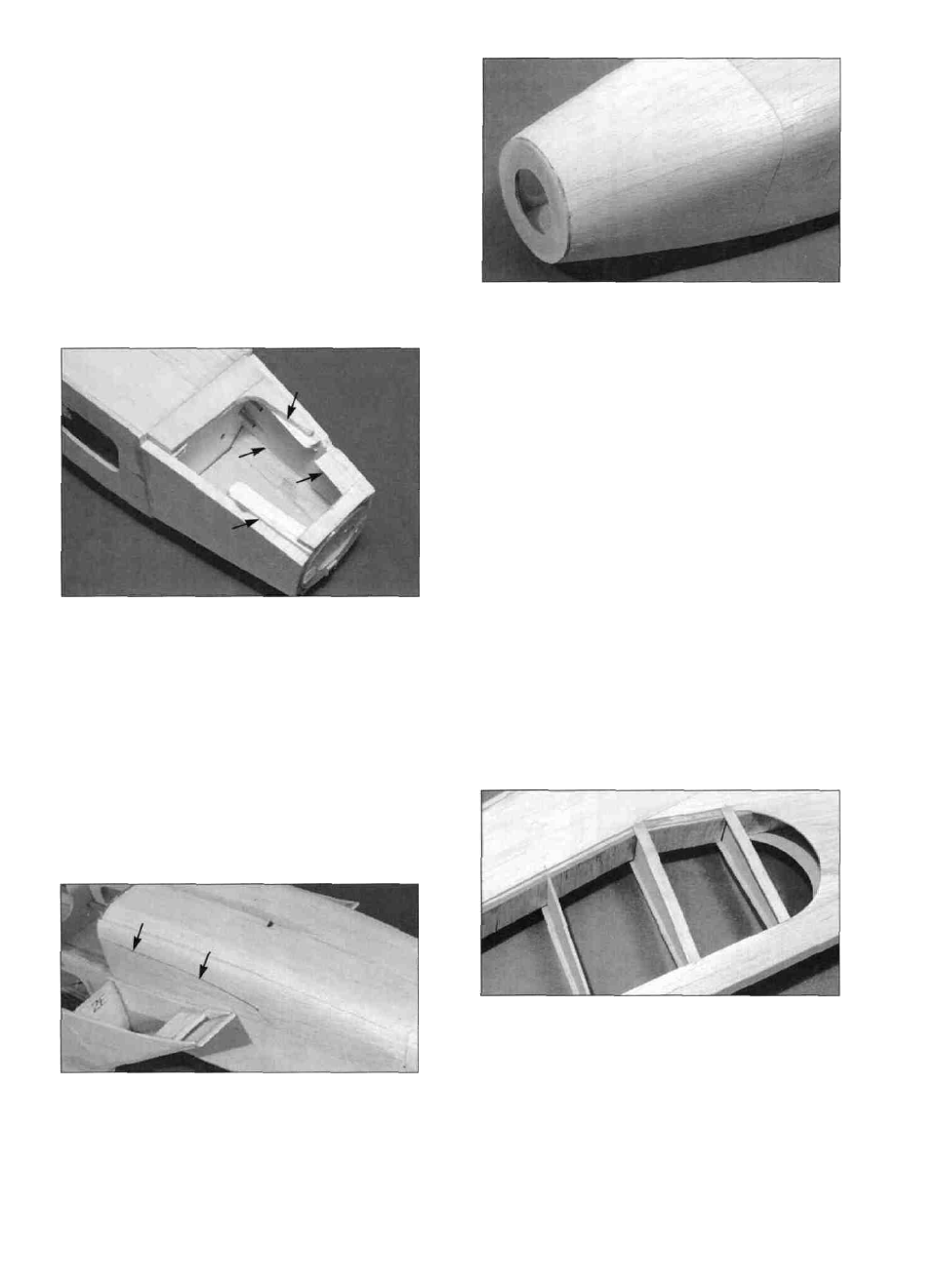

D 10. Remove the prop nut and propeller. Carefully

pop the spinner backplate loose with a screwdriver and

remove the spacers. Remove the engine and mount in

preparation for the next steps. You may have to cut away

some of the scrap wood you just installed to get the

engine out. This is ok, you have to be able to service the

engine.

D 11. Check the fuel tank brass tubes and cut out

around them if necessary so the fuel tubing will slide on

later. If necessary, carve out the area of the nose side if

needed for the nose gear steering arm and pushrod

clearance.

D 15. Using a razor plane and a sanding block with

coarse sandpaper, rough sand the front of the fuselage as

shown above. The nose should be perfectly round at the

spinner ring and flow smoothly to the cross sections

shown on the plans at the firewall and F-2. The bottom

comers should become sharper as they near the inlets and

flow smoothly into the fuse bottom. Do not sand below

the wing outline you drew or you will increase the wing

gap.

D 16. Now, with the engine and mount removed,

fuelproof the inside of the entire engine compartment

with polyester resin or epoxy thinned with alcohol.

D 12. From t h e 1/2" balsa t r i a n g l e stock

(WSTR001H), cut lengths to fit in all the corners of the

nose, between the firewall and the spinner ring. Add

thick CA around the inside of the spinner ring and the

front of the firewall to secure everything.

D 13. Trim the triangle stock as needed to temporarily

re-install the engine and mount. Trim the cowl bottom as

necessary to get the muffler on the engine. Trim the

cowl to allow a 1/8" gap around all engine parts

including the muffler. When satisfied with the clearance,

remove the engine and mount.

D 14. Set the wing on the fuse and draw a line along

the top surface of the wing on the side of the fuselage.

Do this on both sides of the fuse. Remove the wing.

FINAL ASSEMBLY

D 1. From the 1/16" x 3/8" x 30" balsa sticks

(F146W20) cut the cap strips to fit between the leading

edge sheeting and the trailing edge sheeting and glue

them in place over each rib. Do this for both sides of all

the ribs. HINT - For easier positioning of the cap strips,

first mark the location of the ribs on the LE and TE

sheeting.

42