Great Planes F-14 60 Kit - GPMA0435 User Manual

Page 32

make up each EZ connector -

EZCONN01. EZCONN02 and

EZCONN03). The two inner

connectors should be the same

distance from the c e n t e r of the horn. The outer

connector is for the nose gear steering pushrod. Make

sure the plastic washers are fully pushed onto the

connector bodies.

halfway through the hole in the nylon swivels using a

4-40 tap. IMPORTANT - We have noticed that the

swivels are sometimes looser than desired if you tap the

threads all the way through the swivel. This looseness is

not very noticeable but can cause control surface flutter

and therefore cannot be permitted. Cut the threads a

little at a time, checking the swivel on the torque rod

each time until it rotates with very little friction. Cut the

excess threads off of the torque rod just past the swivel.

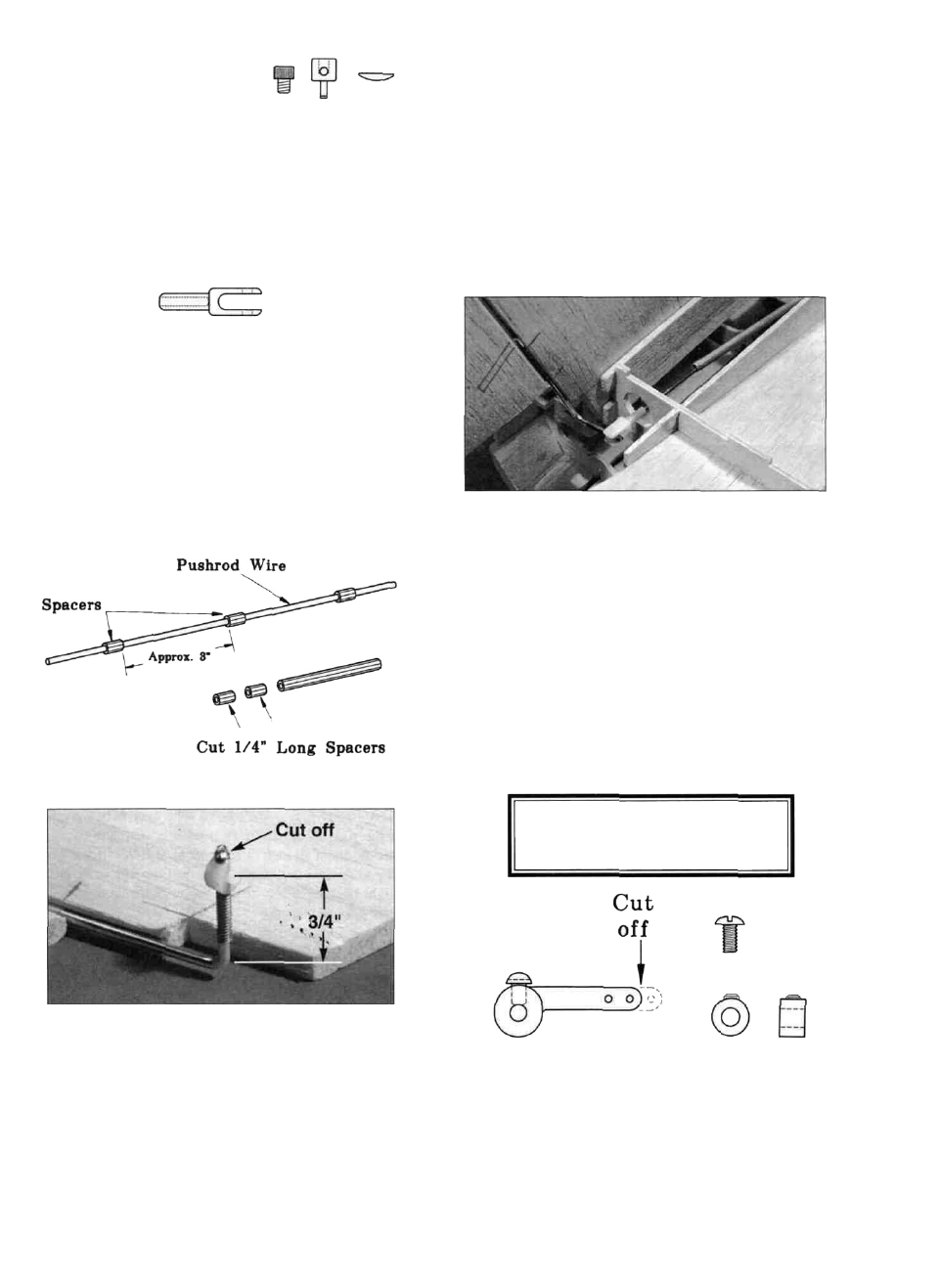

D 12. Screw a nylon swivel clevis (NYLON21) 3/4 of

the way onto the end of t w o 34" pushrod wires

(WIRES 17). Cut 1/4" long spacers from the 6-1/2" piece

of yellow pushrod inner tube (PLTB004) and slide 7

spacers onto each wire approx. 3" apart. Note: If these

spacers do not slide on easily, cut them to a shorter

length. When installing pushrods, position the plastic

spacers so they always stay inside the pushrod guide

tubes. If the spacers are not a tight fit on the pushrod

wires, apply a drop of thin CA to secure each spacer.

D 14. Hook the swivel clevises up to the nylon swivels

on the torque rod. Install the torque rods in the fins and

rudders, slide the rudder pushrod wire into the outer

tubes and insert the fin/rudder assemblies into their slots.

The p u s h r o d wires should pass t h r o u g h the EZ-

connectors and any excess wire should be cut off about

1" past the connector. Check the movement of the

rudders to make sure the clevises don't bind on former

F-7. Trim the holes in F-7 if necessary to allow the

torque rods to move freely. Remove the fins and rudders

but leave the torque rods attached to the swivels. The

torque rods can be rotated and tucked down between the

fin supports.

D 13. Screw a nylon swivel (NYLON20)

onto each of the four small torque rods

( W B N T 1 6 8 ) . NOTE: The t o r q u e rod

swivels m u s t be loose enough to swivel

freely; therefore, we recommend that you cut threads

STEPS 15 AND 16 ARE FOR

FIXED GEAR ONLY!

D 15. Cut 1/4" off the end of the nylon steering arm

(NYLON 16) as shown in the sketch above. Install the

steering arm on the nose gear strut using the 5/32" wheel

collar (WHCL005) and the 6-32 x 1/4" pan head screw

32