Drill engine mount – Great Planes F-14 60 Kit - GPMA0435 User Manual

Page 34

position and mark on the pushrod wires where to cut

them off (approx. 1/16" before the coupler tapers down).

have to file the comers of the engine mount rails to make

room for the crankcase. If the mount would require a

large amount of filing, just replace the mount with one

that correctly fits your engine.

D 21. Remove the elevator pushrods from the fuselage

and cut them oft at the mark. Remove the nylon clevises

from the threaded couplers and solder the couplers to the

wires with acid core solder. After things cool down,

replace the clevises and hook the pushrods up to the

servos. Move each servo arm throughout its range and

check the elevator movement for binding. Adjust the

clevises until the elevators are at neutral when the servo

arms are at neutral. Trim the holes in formers F-6 and

F-7 if necessary to obtain clearance for the elevator

pushrods. Remove the stabs and elevators but leave the

torque rods attached to the swivels. The torque rods can

be rotated and tucked in between the stab supports.

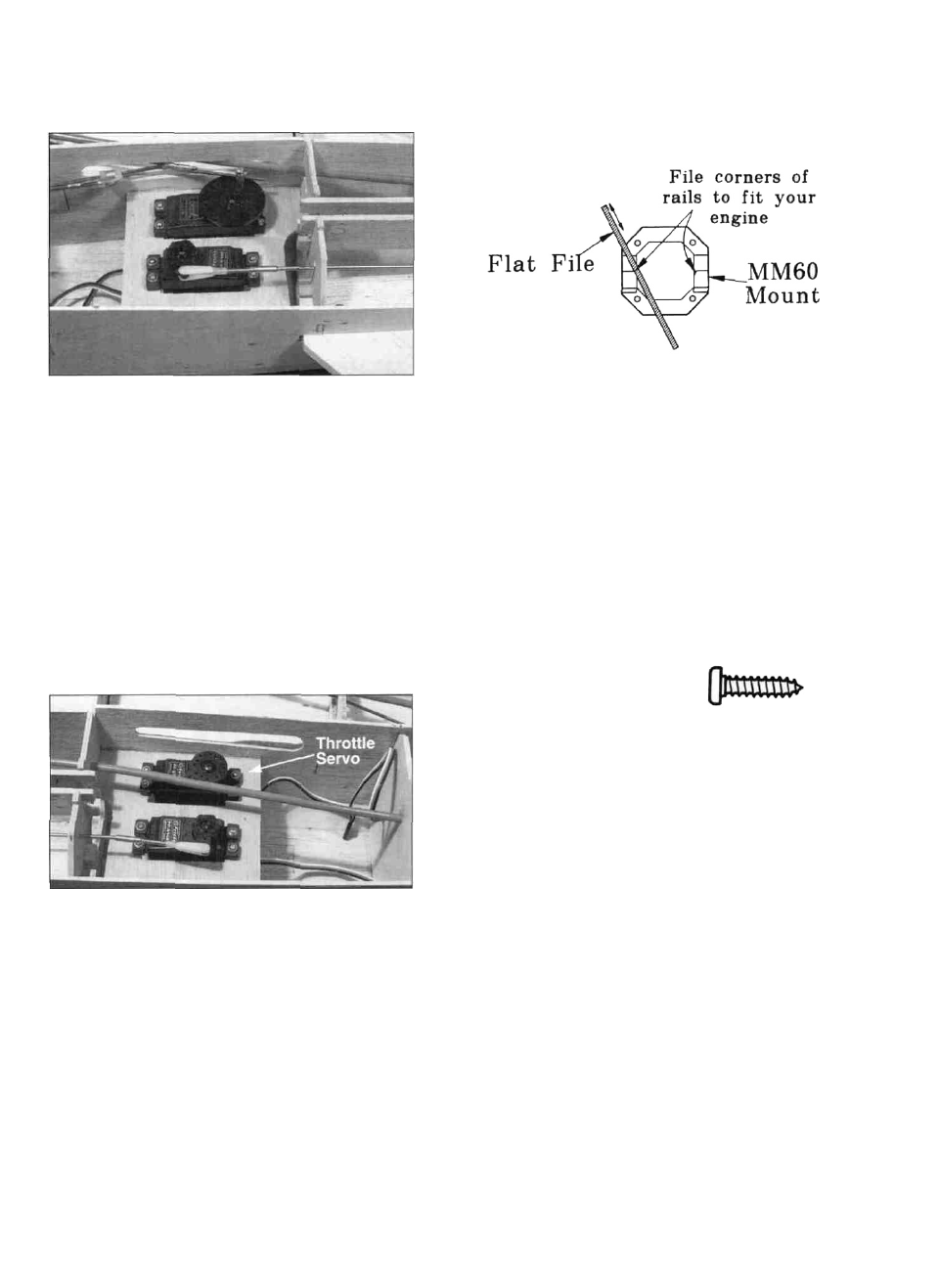

D 1. Place the engine pointing straight ahead on the

mount (in the approximate location shown on the plans)

and mark the mounting hole locations on the mount. At

the marked locations, accurately drill 7/64" (or #36)

holes. NOTE: If you have access to a drill press, use it

for drilling these holes to insure that they are drilled

vertically.

D 2. Now you may use one of the following methods

to attach your engine to the mount:

Method 1: Screw the #6 x 3/4" sheet metal screws

(provided in the kit) through the

engine mounting flange and into

the mount. When first installing

these screws, put a drop of oil

into each screw hole.

Method 2: Cut threads into the holes you just drilled

using a 6-32 tap and tap wrench. If you use this method,

you'll have to supply your own bolts (6-32 x 1" socket

head cap screws) for attaching the engine to the mount.

D 22. I n s t a l l the t h r o t t l e servo u s i n g the screws

provided with your radio. It should be installed in the

remaining rear servo tray opening to help balance the

airplane.

D 3. Attach the engine mount to the firewall using the

6-32 x 5/8" cap screws.

DRILL ENGINE MOUNT

(Great Planes MM60D90 or similar glass-filled nylon

mount)

NOTE: If the engine mount supplied in the kit does not

appear to fit your engine (example: OS .61 SF), you may

D 4. Screw your engine to the mount, and determine

the location where the throttle pushrod w i l l pass

through F-1. Due to the length of the throttle pushrod, a

flexible plastic pushrod (not included) works well for

this. Drill a 3/16" hole (or whatever size you need) in

the firewall for the throttle pushrod guide tube. The hole

should be 1/4" away from the outside of the fuselage to

34