Great Planes F-14 60 Kit - GPMA0435 User Manual

Page 41

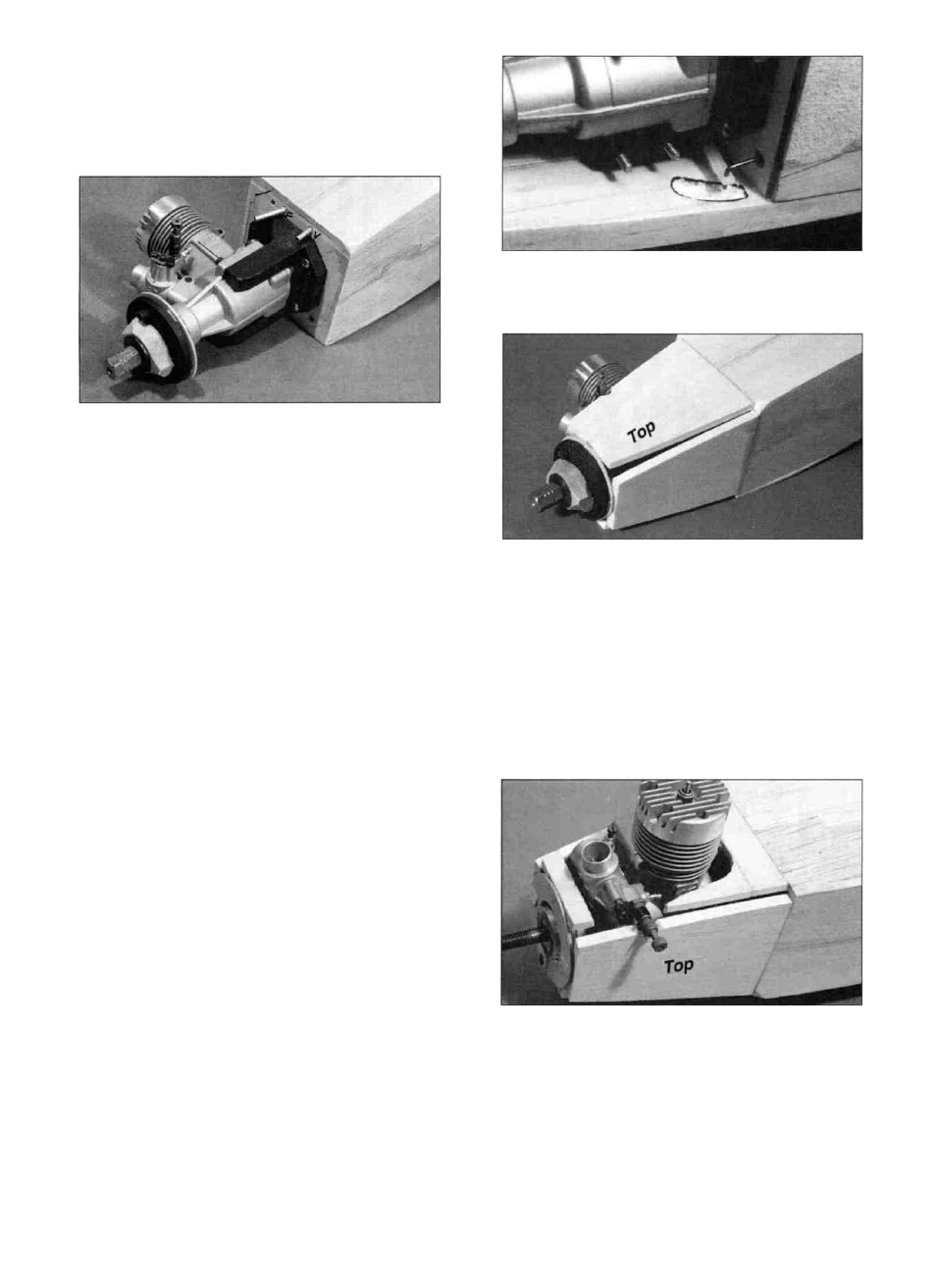

D 3. Now center your 2-1/4" diameter spinner

backplate (HCAQ3750 recommended) over the spinner

ring, and tack glue it to the 1/16" spacers.

D 4. S l i d e the s p i n n e r r i n g / s p i n n e r backplate

assembly onto the drive shaft and temporarily hold it in

place with the prop and prop nut. (Photo shows only the

hub of an old prop).

D 5. Locate the three identical 1/4" shaped balsa

cowl pieces (F146F29) in the kit. With the fuselage

upside down, trial fit one of the pieces in place on the

bottom of the engine compartment. Study the plan to see

the correct positioning of this part. The cowl pieces

should be centered in relation to the side they are

installed on. Note how the front of the cowl piece meets

the spinner ring. By trial and error, sand a little at a time

off the front and rear of the bottom cowl piece until it

mates at the proper angle with the firewall and the back

of the spinner ring. Now glue the cowl piece to the

firewall and the spinner ring.

nose gear pushrod in the cowl piece. Now remove the

nose gear parts.

D 8. Custom f i t another cowl piece for the top of the

nose between the firewall and the spinner ring, trimming

as necessary for needle valve clearance. Also fit the

remaining cowl piece to the side of the nose. When

satisfied with the fit of these two pieces, glue them in

place. NOTE: The corner gaps are intended to be there.

Later, they will help gauge when the nose has been

sanded enough.

NOTE: If you have installed a retractable

nose gear, skip steps 6 and 7.

D 6. Turn the fuselage right side up and use a long

5/32" drill bit (or a sharpened piece of 5/32" O.D. brass

tube) to drill a hole in the bottom cowl piece for the nose

gear strut. Insert the drill through the holes in the engine

mount and drill down through the bottom cowl piece.

D 7. Temporarily install the nose gear, steering arm

and nose gear pushrod wire. Notice that the steering arm

and the pushrod wire will bind against the cowl piece,

especially in a turn. Carve out a clearance slot for the

D 9. Use scraps of 1/4" wood (from the t u r b i n e

corners) to fill in around the engine side of the nose.

SUGGESTION: The temptation is to close up this area

too much! We recommend that you leave large enough

openings to allow you to easily remove the engine and

mount and also have convenient access to the throttle

linkage.

41