Cut the main gear retract openings – Great Planes F-14 60 Kit - GPMA0435 User Manual

Page 46

so you can compare how they fit in relation to each other.

They should both be located the same distance forward

and when compared from the side and above, they should

be aligned with each other.

CUT THE MAIN GEAR RETRACT

OPENINGS

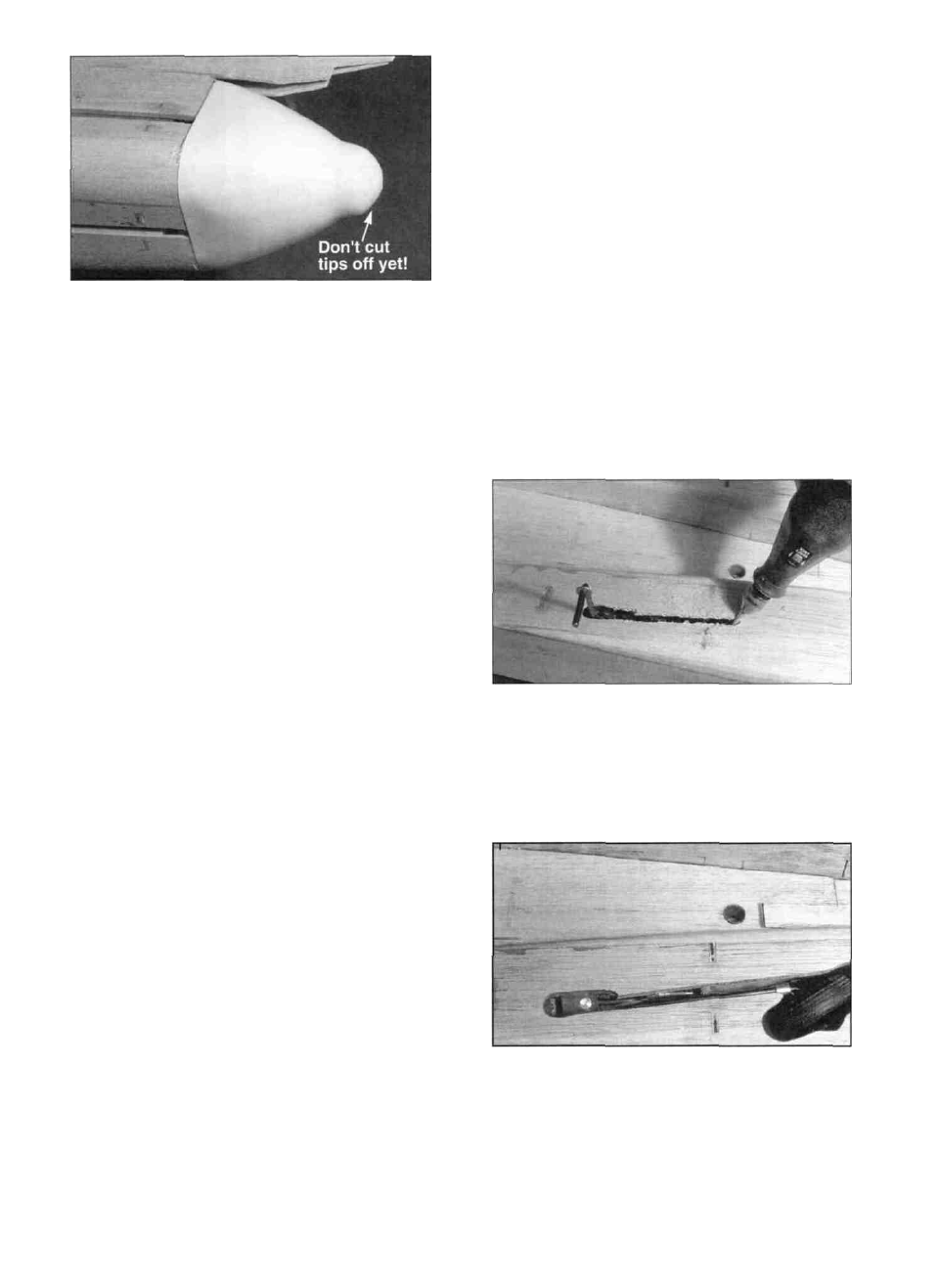

The retract openings are made using a fit and cut type of

operation that will take a little time but is not hard to do.

D D 1. Insert the right main gear strut in the right

side retract to the proper depth and tighten the set screw.

This is tough to do because the ball driver is way down

inside, but it can be done. A long nose pliers may come

in handy.

D D 2. Retract the strut until it hits the edge of the

opening and notice where it touches the wood. Cut a

small notch there and allow the strut to retract a little

farther. Make another small notch and allow the strut to

retract a little farther. A Dremel tool with a small carbide

grinder will make this process much easier.

D 5. When satisfied with the fit of the nozzles, rotate

the rudder and elevator torque rods and insert them in the

f i n and stab slots so they w i l l be out of the way.

Correctly position the nozzles and then add thin CA

around the edges of the nozzles.

D 6. Cut the tips off both nozzles by trimming them

along the scribe line and then lightly sanding them to

match each other in length. Save the tips to test paint

and iron temperatures on later. NOTE: If you prefer a

larger outlet in the tail cones, you can trim and sand them

closer to the fuselage. Add thick CA around the inside

of each nozzle where the fuse wood stops.

D 7. Insert the fins, stabs and die-cut 1/8" ply ventral

fins (F146F32) into their appropriate slots. Sand the fins

and stabs if necessary to get them to fit all the way down

into the slots. Install the torque rods in the fins and

stabs. Carefully trim the ABS nozzles if needed to get

these items to fit. IMPORTANT - When trimming the

nozzles, do not leave any "corners" in the cut outs.

Always make nice circular cuts and sand the edges of the

cut with fine sandpaper. A corner will eventually allow a

stress crack to form. While these surfaces are inserted in

the fuselage, lightly draw a line on the fins, stabs and

ventral fins marking where the fuse joint is. This will

tell us how far to cover these surfaces later. The nozzles

can be painted after the plane has been covered

D 8. Use scraps of wood and lightweight wood filler

to fill in between the rear of the fuse top and the fuse

bottom. Use the filler to blend the exhaust nozzles into

the fuse and sand this area smooth.

D D 3. Continue this process until the strut can fully

retract into the fuselage. Install a 2-1/4" wheel on the

strut and perform the same type of fit and cut procedure

until the wheel will fit into the fuselage.

D D 4. C a r e f u l l y trim the edges of the retract

opening to smooth them out and make them look nice

and symmetrical. A Dremel tool with a small sanding

drum or a fine grit carbide drum works well for this.

46