Great Planes F-14 60 Kit - GPMA0435 User Manual

Page 16

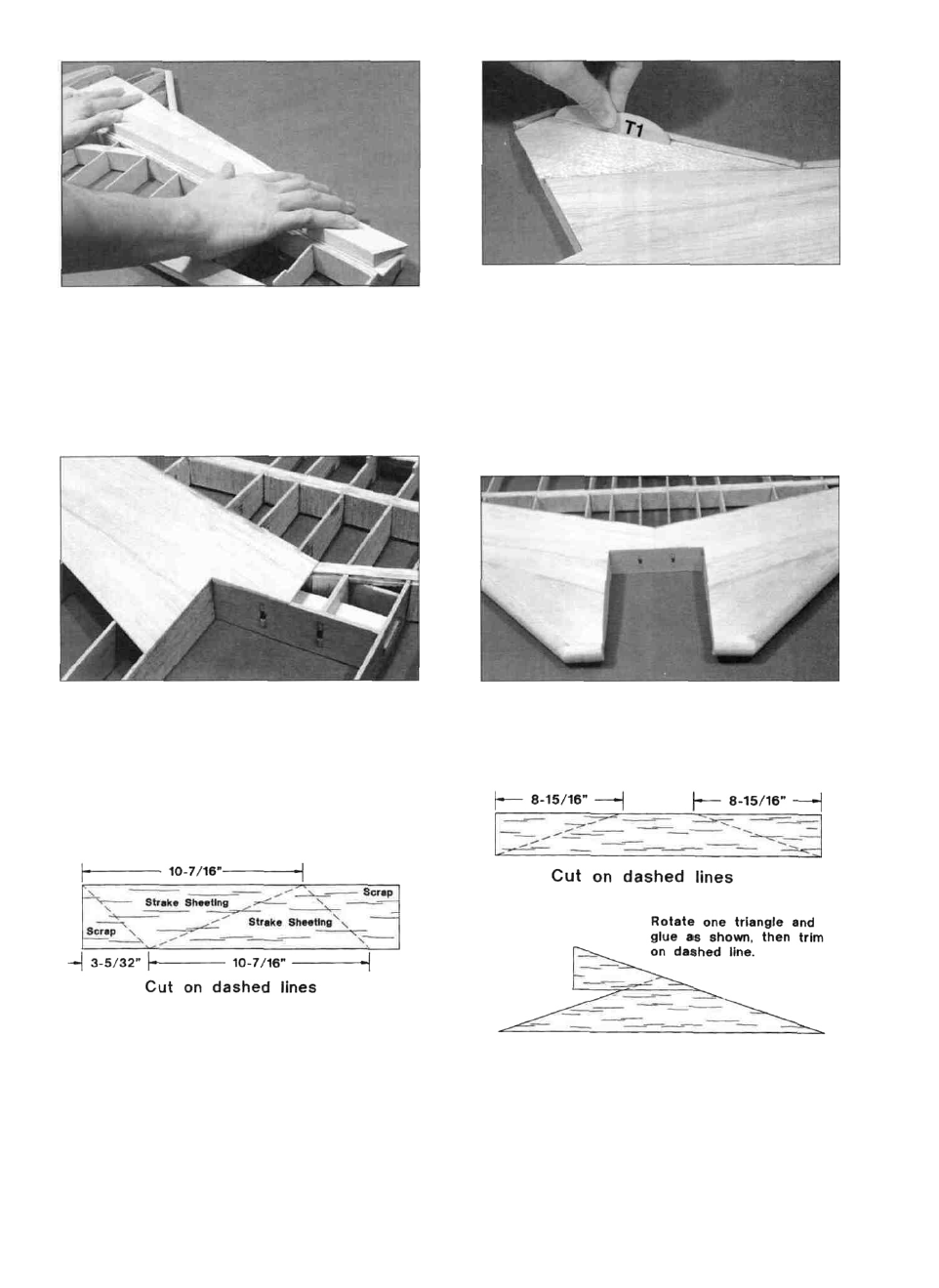

front edge of the spar. Immediately place the wing on

your flat work surface and press the sheeting into place.

Use a piece of wood (an aileron works OK) to hold the

sheeting in place while the glue cures. It is important to

keep the wing flat during this process as the LE sheeting

will "lock" the wing together.

D 10. First glue the sheeting against the LE sheeting

already in place. Try to line up the edges as closely as

possible. Drip some thick CA down the ribs and press

the sheeting into place. Add CA along the LE and use a

small but flat piece of wood to keep the sheeting straight

along the LE (turtle deck former T1 works well for this).

Trim the end of the sheeting flush with rib W2.

D 8. Trim the tip end of the sheeting flush with rib

W11. Trim the root end of the sheeting flush with the

centerline of the wing, rib W2 and the wing front plate.

D 11. Sheet the opposite wing panel using the same

procedure outlined above.

D 9. Cut the four pieces of 1/16" x 3" x 15" balsa

stock sheeting (F146W23) as shown in the sketch

above. Test fit one of the pieces in place in front of the

leading edge sheeting and trim and sand it as necessary

to make it fit. NOTE: The grain should run along the

LE.

D 12. Cut two 1/16" x 3" x 24" balsa center sheets

(F146W15) and assemble two triangles as shown above.

Use one in the next step and save the other for the bottom

of the wing.

16