Install aileron torque rods – Great Planes F-14 60 Kit - GPMA0435 User Manual

Page 18

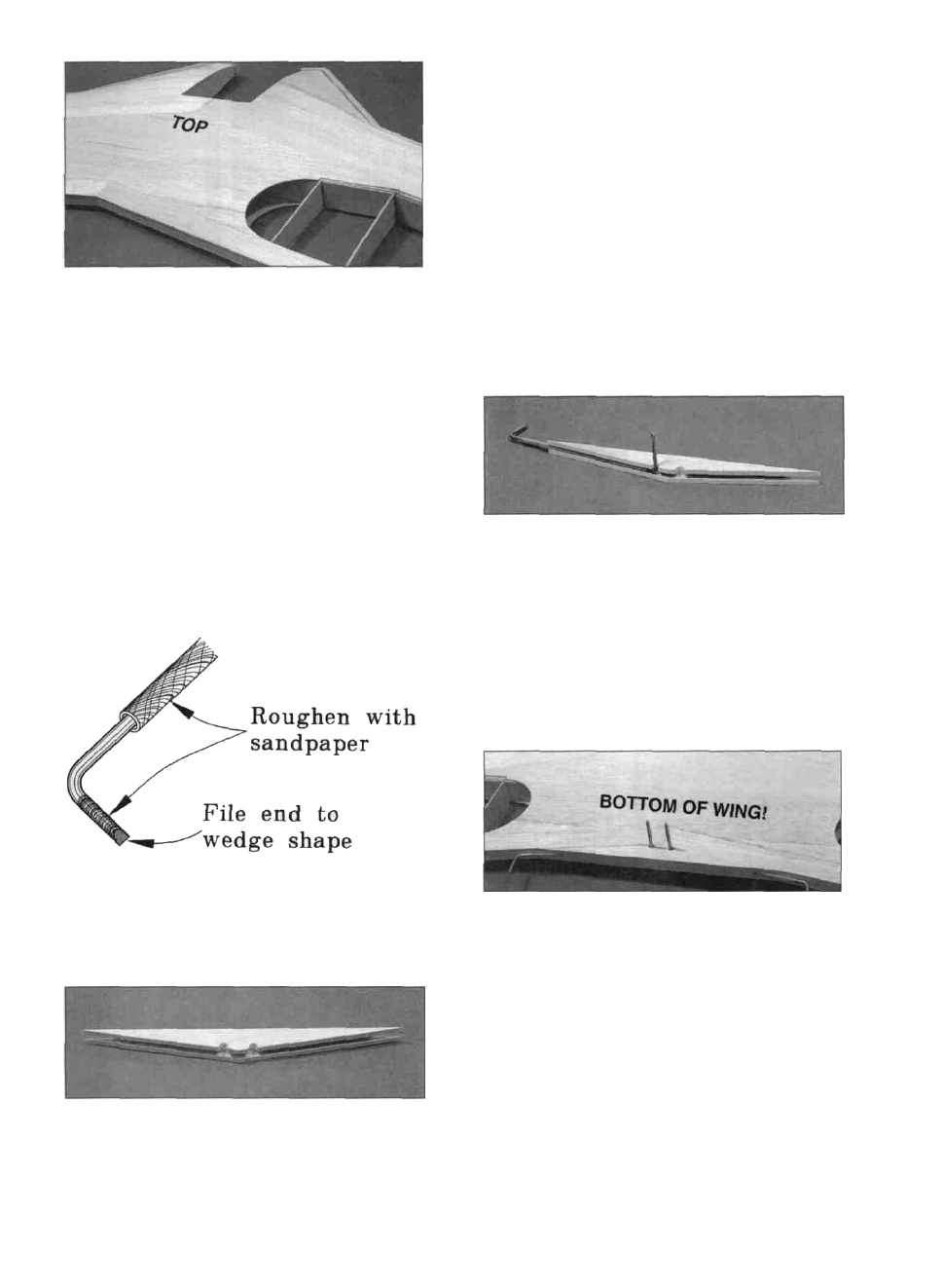

D 19. Flip the wing over. On the side that still has the

jig tabs attached, write the word "top" near the center of

the wing. Trim and sand off the remaining jig tabs.

Touch up the ribs with a fine grit sanding block and add

the rear sheeting just as you did in steps 17 and 18. Trim

all sheeting flush with the W11 ribs and lay the wing

aside until later.

INSTALL AILERON TORQUE RODS

rods come up through it. Cut notches there to clear the

torque rods. Test fit the wedge on the wing and sand it if

needed to get a good fit. Test fit the torque rods in the

groove to make sure they fit OK. If not, sand the groove

and notch u n t i l they do. Also cut small clearance

notches on the bottom side of the w i n g where the

threaded portion of the torque rod will be located. Note:

The torque rod horns must exit the BOTTOM of the

wing!

D 5. Slide the plastic bearings toward the threaded

end of the torque rods. Then use a toothpick to apply a

small amount of petroleum jelly to the ends of the plastic

tubes (to help prevent glue from getting inside and

locking up the torque rods).

D 1. Roughen the un-threaded end of the aileron

torque rods (WBNT167) with 100-grit sandpaper, and

file the same end to a wedge shape.

D 6. Use epoxy to glue the plastic bearing tubes into

the grooves in the rear wedge. Make sure the torque rods

are fully seated in the groove. Wipe off any excess glue

and allow it to harden.

D 2. Roughen the surface of the plastic bearing tubes

with 100-grit sandpaper.

D 3. Clean the torque rods and bearing tubes with

alcohol.

D 4. Position the 1/2" balsa grooved rear wedge

(F146W10) over the plans and mark where the torque

D 7. Sand the TE of the wing to make it straight with

square edges.

D 8. T r i a l f i t the rear wedge/torque rod assembly

onto the wing trailing edge. It should be centered up and

down on the wing TE so the torque rods are located at

the centerline of the TE. Sand the TE if necessary to get

a good fit then glue the wedge in place w i t h epoxy.

HINT: Use masking tape to hold the wedge against the

wing TE and to aid in positioning it.

D 9. Locate the tapered balsa center TE (F146W09)

(it is 10-1/8" long and has the same cross section as the

18