Table 12.2) – Flintec FT-10xx User Manual

Page 77

FT-10 Smart Process Indicator, Technical Manual, Rev. 1.0, January 2014

Page 76 of 82

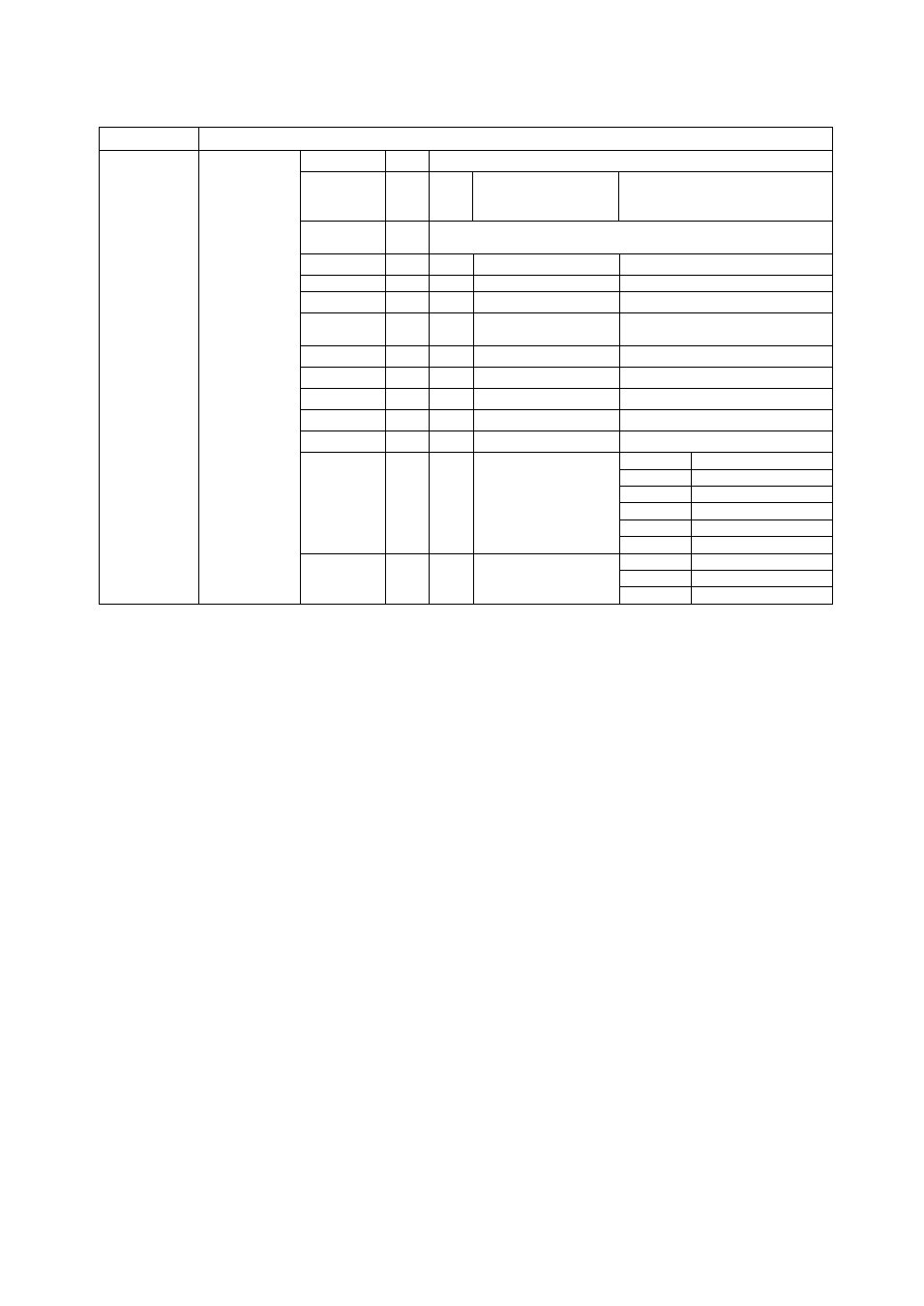

Expanded Command List (always 32 bit integer)

The “D48 … D55” bits in RxPDO describes below.

Bit No

Description

D48…D55

Expanded

Commands

List

Bin

Dec

Commands

00000000

0

R

Voltage of

Power Supply

Voltage of power supply is

indicated with 0.1 VDC

increment.

00000001

00111111

1

63

Not in use

01000000

64

RW

Filter

(1)

Refer to par. [120] on page 29

01000001

65

RW

Power On Zero

(1)

Refer to par. [202] on page 30

01000010

66

RW

Zeroing Range

(1)

Refer to par. [203] on page 30

01000011

67

RW

Auto Zero Tracking

(1)

Refer to par. [204] on page 30

01000100

68

RW

Tare

(1)

Refer to par. [205] on page 30

01000101

69

RW

Motion Detector

(1)

Refer to par. [206] on page 30

01000110

70

RW

Stability Period

(1)

Refer to par. [207] on page 30

01000111

71

RW

Operation mode

(1)

Refer to par. [210] on page 31

01001000

72

RW

Capacity

(1)

Refer to par. [212] on page 31

01001001

73

RW

Decimal point

(1)

0

XXXXOO

1

XXXXXO

2

XXXXXX

3

XXXXX.X

4

XXXX.XX

5

XXX.XXX

01001010

74

RW

Increment

(1)

1

X1

2

X2

3

X5

Table 12.2 - Expanded Command List

(1) Write this command with writing values to D0~D33 bits then apply New CMD.

Programming steps of frequent used

……

Reading a weight value:

1.

Check the D44…D47 bits of ‘TxPDO 1 (T_UL1)’.

2. If there is not any error, read a weight value ( gross, net or tare),

Zero Calibration procedure:

1. Check the low byte of Calibration Status. it should be decimal '1' to start adjustment.

2.

Write ‘Adjust Zero Calibration’ command and apply New CMD to start Zero calibration.

3. Check the low byte of Calibration Status. it is decimal '3' during zero calibration process.

4. The low byte of Calibration Status changes to decimal '1' at the end of the Zero calibration.

5. If the low byte of Calibration Status is '9', check the high byte of Calibration Status to understand the

calibration error.

Span Calibration procedure:

1. Check the low byte of Calibration Status. it should be decimal '1' to start adjustment.

2.

Write ‘Adjust Span Calibration’ command with writing test weight values to Low Dword of RxPDO1

(R_UL1), then apply New CMD to start Span calibration.

3. Check the low byte of Calibration Status. it is decimal '4' during span calibration process.

4. The low byte of Calibration Status changes to decimal '1' at the end of the Span calibration.

5. If the low byte of Calibration Status is '9', check the high byte of Calibration Status to understand

the calibration error.