1 entering the programming and calibration, Rogramming and, Alibration – Flintec FT-10xx User Manual

Page 22

FT-10 Smart Process Indicator, Technical Manual, Rev. 1.0, January 2014

5. P

ROGRAMMING AND

C

ALIBRATION

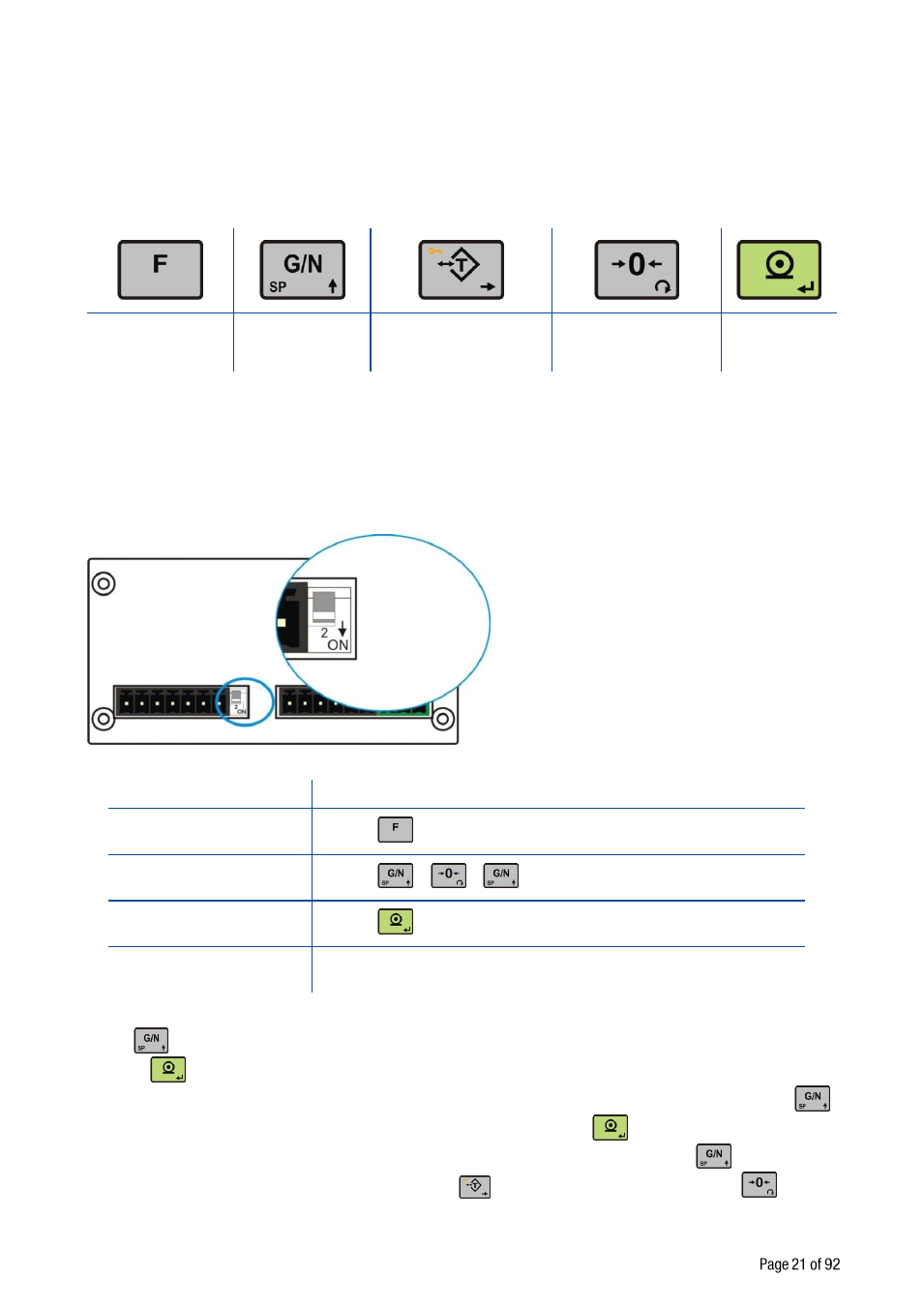

In this section you will find the programming and calibration procedure of FT-10 indicator according to your

application. The signs those take place on the lower right corner of the keys indicate the function of the keys

in programming menu. The basic meanings of these keys are given the table below.

Exit without saving Advancing next

parameter

Select the digit will be

changed

Changing parameter

value or increasing the

blanking digit

Enter

5.1 Entering the Programming and Calibration

There is a DIP switch on FT-

10’s rear side and its position should be “ON” ( downward ) to change the

metrological related parameters including calibration. There is no need to open the housing to change the

position of this DIP switch. If there is not set-up DIP switch on the instrument for industrial usage, its position

is always ON.

Figure 5.1 - The location of calibration DIP switch

Display

Operation

[123.456 kg]

Press

key until [ PASSWr ] prompts seen.

[PASSWr]

Press

+

+

keys sequentially.

[--- ]

Press

key for confirm.

[0-- ]

First block of Programming menu.

Programming and Calibration menu consist of main blocks which are shown as [X-- ] and sub-blocks. By

using

key you can reach next main blocks. After reaching the desired main block, you can get in by

pressing

key. As you enter the block you will reach the first sub-block in that main block. The sub-block

address will be seen on the display as [X0- ]. You can also search between the sub-blocks by using

key and reach the first parameter of the sub-block seen on the display by

key. The number of the

parameter comes on display as [XY0 ]. Again you can search between parameters by

key. For

entering numerical value in the parameters, press the

key to select the digit and press the

key the

change the value.