Adjustments and calibration, Rotation setup and override, Caution – KMC Controls CEP-4000 Series User Manual

Page 3

CEP-4000 Series

3

Installation Guide

Rotation Setup and Override

If desired, the rotation direction can be reversed by

swapping the red and blue motor wires according to

the following table:

Adjustments and Calibration

Each CEP-4000 is calibrated to its SSE series sensor at

the factory. No further calibration is needed. If the

units are replaced or become mismatched, complete

the following steps to recalibrate the controller and

sensor.

1.

Follow steps 1 and 3 under the Wiring section.

Connection of the thermostat is not necessary.

2. Connect the voltmeter “+” to CEP terminal 2 and

“–” to CEP terminal 4.

3. Ensure zero airflow in the duct or remove the

sensor from the duct and place it in a horizontal

position with

zero airflow.

4. Wait 5 minutes for the CEP and SSE units to

stabilize.

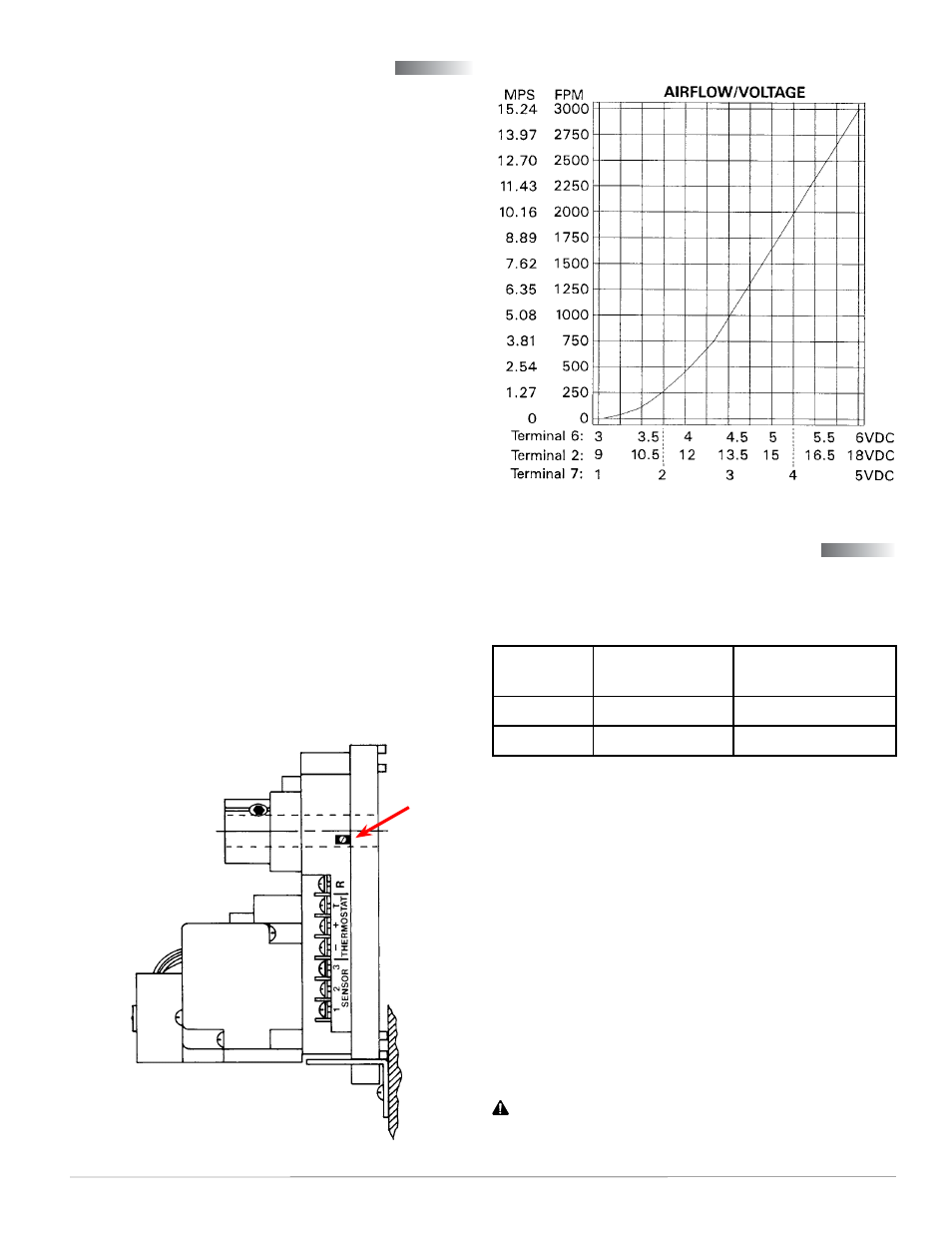

5. Access the trimpot through the slot in the CEP-

4000’s side. The slot is normally covered by a

label and is on the sensor/thermostat connection

side (see illustration below).

6. Adjust the trimpot until the voltmeter reads 9

volts. When the adjustment is made, the voltage

will immediately overshoot and then stabilize.

This reestablishes the baseline. (See the CEP-4000

Airflow vs. Voltage chart.)

7. Wait an additional 5 minutes for the CEP and SSE

units to stabilize.

8. Readjust if necessary.

Rotation

to Close

Motor Wire to

Terminal 12

Motor Wire to

Terminal 14

CCW

Red

Blue

CW

Blue

Red

CAUTION

Do not short terminals 12 and 14, 4 and 5, or 2

and 4.

CEP-4000 Trim Potentiometer

NOTE: Motor wires must remain connected to

terminal screws (11, 12, and 14) due to

components beneath terminals.

CEP-4000 Airflow vs. Voltage

To manually drive the controller/damper open or

closed (with 24 VAC on terminals 9 and 10), remove

the wiring to terminal 6, and temporarily jumper

terminal 6 to:

• Terminal 5 (9.1 VDC) = Open

• Terminal 4 (– VDC) = Closed

NOTE: Full rotation may take five to six minutes

because the actuator rotates at 18° per

minute. A magnetic slip-clutch inside the

actuator allows motor to continue running

even when end-stops have been reached.