Wiring a pressure sensor, Wiring a vent sensor, Ems connection – tekmar 284 Boiler Control User Manual

Page 29: Modbus, Connection, Bacnet, Ems, modbus, Connections, Terminals 13 to 15, Terminals 23, 25

© 2014

284_D - 08/14

29 of 60

A Watts Water Technologies Company

5V

dc

Out

Pressure

Sensor

In

+

14

Vdc

-

15

Gnd

13

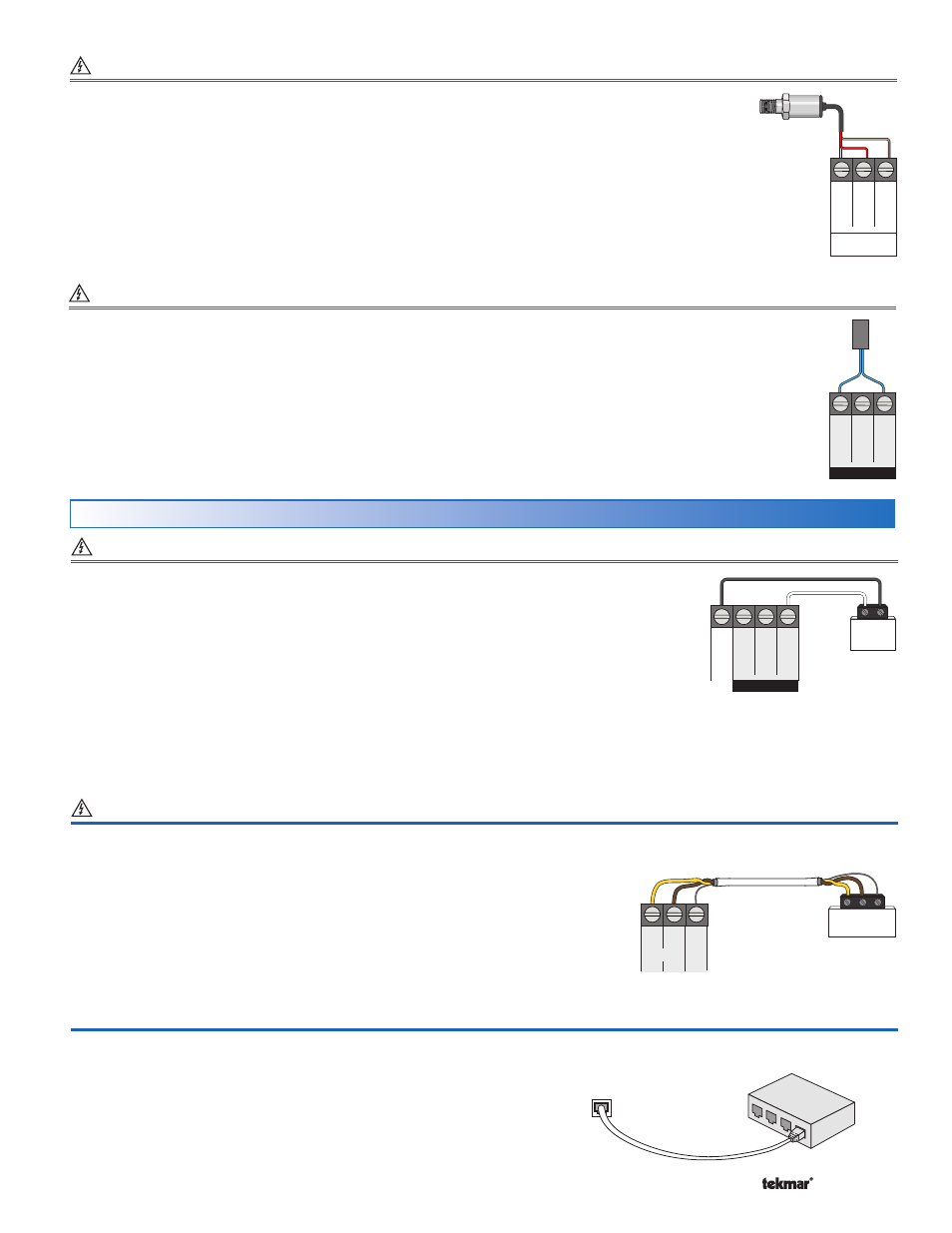

Wiring a Pressure Sensor

Terminals 13 to 15

An analog pressure sensor can be connected to the 284 to provide water pressure monitoring. The

control supports a V (dc) style pressure sensor with a signal range of 0.5 to 4.5 V (dc). Examples

of compatible aftermarket pressure sensors include the Honeywell PX2 (AA) series and the

Measurement Specialties 7100 series.

Connect one wire from the power supply (+5 VDC) on the pressure sensor to the 5V dc Out

terminal 13.

Connect one wire from the pressure signal on the pressure sensor to the Vdc (+) In terminal 14.

Connect one wire from the GND (0V) on the pressure sensor to the Gnd (-) terminal 15.

•

•

•

No Power

Boil

In

Vent

23

24

25

Com

Wiring a Vent Sensor

Terminals 23, 25

A vent sensor can be connected to the 284 to provide monitoring of the common boiler plant exhaust vent temperature.

Compatible sensors include a 10K ohm NTC curve J thermistor.

The control is capable of displaying temperatures up

to 500

°

F (260

°

C).

The vent sensor can also be used to provide a vent temperature limiting feature.

Connect one wire from the vent sensor to the Vent terminal 23.

Connect the second wire to the Com terminal 25.

•

•

+

-

EMS

No Power

Com

Out

17

Boil

Sup

18

-

19

In

EMS

+

16

EMS Connection

Terminals 16, 19

Modbus

®

Connection

Terminals 40 to 42

BACnet

®

Connection

RJ45 Plug

A Building Automation System (BAS) can be connected to the 284 for remote

monitoring & adjustment capability. BACnet

®

IP communications use an

ethernet socket. Use a CAT-5E or CAT-6 cable. The maximum recommended

cable length for CAT-5E is 150 ft. (45.7 m) & 300 ft. (91.4 m) for CAT-6.

Connect the Ethernet RJ45 socket on the BACnet

®

IP network to the

Ethernet RJ45 socket on the 284.

•

A Building Automation System (BAS) can be connected to the 284 for remote monitoring

& adjustment capability. Modbus

®

communications use an RS 485 connection. Use

18 AWG Twisted Shielded Pair cable. Cable length is dependent on the baud rate &

whether or not terminating resistors are used. Refer to the BAS Integration Manual

284_B for details on the maximum recommended cable length.

Connect the B (+) terminal on the BAS network to the RS 485 B (+) terminal 40.

Connect the A (-) terminal on the BAS network to the RS 485 A (-) terminal 41.

Connect the ground (G) terminal on the BAS network to the Gnd terminal 42.

•

•

•

An Energy Management System (EMS) can be connected to the 284 to provide a target water

temperature. Either a 0 to 10 V (dc) or 2 to 10 V (dc) signal may be used.

Connect one wire from the EMS to the EMS (+) In terminal 16.

Connect a second wire from the EMS to the Com (-) terminal 19.

A 0 - 20 mA signal can be converted to a 0 - 10 V (dc) signal by installing a 500 Ω resistor in

parallel between the Com (-) & EMS (+) In terminals (19 & 16). The EMS Signal setting must

be set to 0-10.

•

•

BACnet

Network

Switch

Boiler

Control 284

EMS, Modbus

®

& BACnet

®

Connections

B A G

Master

284

40

41

42

Gnd

+

–

RS 485

B

A

(+) (-)

A 4 - 20 mA signal can be converted to a 2 - 10 V (dc) signal by installing a 500 Ω resistor in parallel between the Com (-) &

EMS (+) In terminals (19 & 16). The EMS Signal setting must be set to 2-10.

The APP MODE setting in the Setup Menu must be set to EMS.