Installation, Important safety information, Radio frequency interference installation location – tekmar 284 Boiler Control User Manual

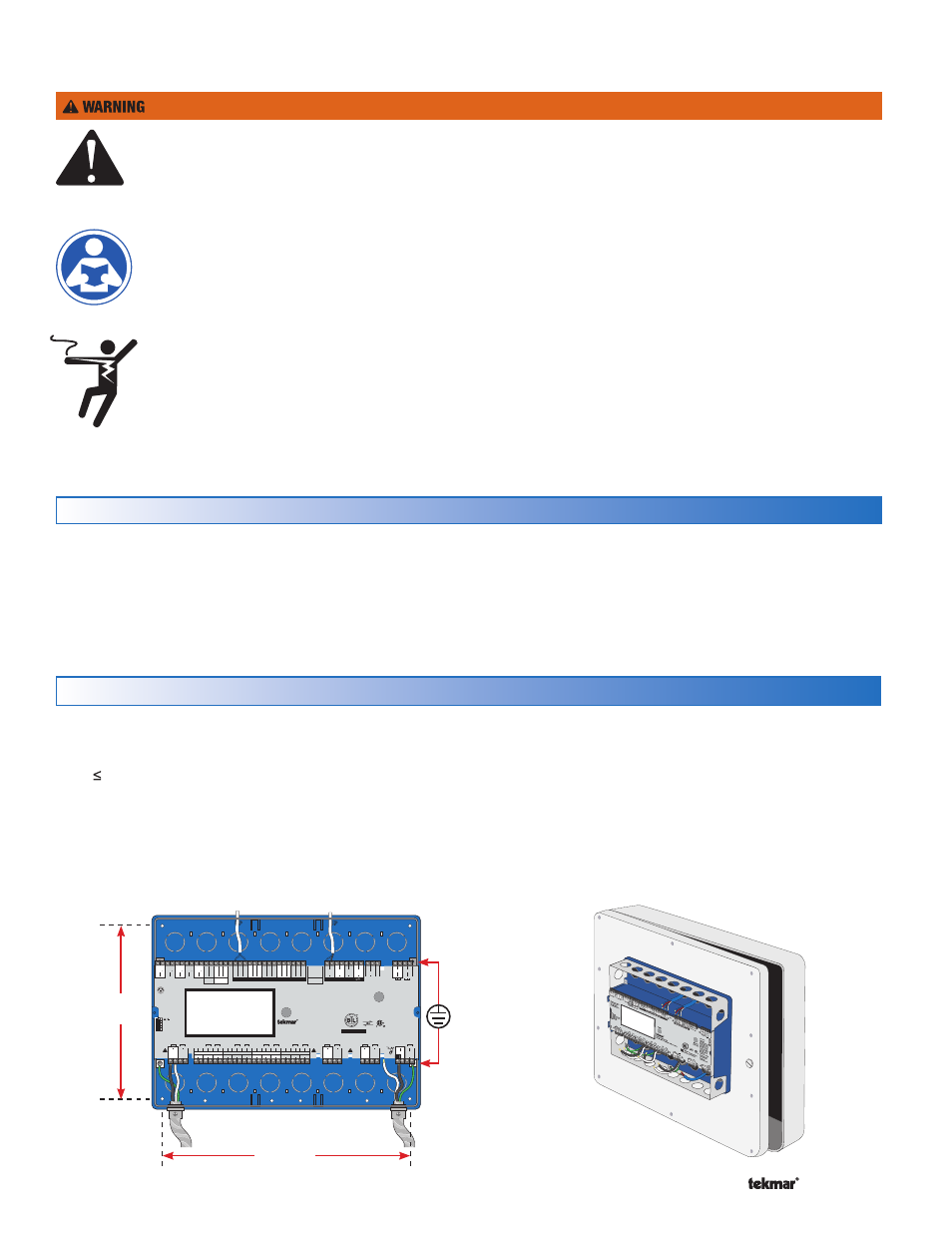

Page 22: Figure 1, Figure 2, 259 mm) screw hole dimensions, Custom panel or electrical box wall or panel door

© 2014

284_D - 08/14

22 of 60

A Watts Water Technologies Company

Installation

The installer must ensure that this control & its wiring are

isolated &/or shielded from strong sources of electromagnetic

noise. Conversely, this Class B digital apparatus complies

with Part 15 of the FCC Rules & meets all requirements of

the Canadian Interference-Causing Equipment Regulations.

However, if this control does cause harmful interference to

radio or television reception, which is determined by turning

the control off & on, the user is encouraged to try to correct

the interference by re-orientating or relocating the receiving

antenna, relocating the receiver with respect to this control,

&/or connecting the control to a different circuit from that to

which the receiver is connected.

Cet appareil numérique de la classe B respecte toutes les exi-

gences du Règlement sur le matériel brouilleur du Canada.

Radio Frequency Interference

Installation Location

When choosing the location for the control, consider the

following:

Keep dry. Avoid potential leakage onto the control.

RH 90% to 104°F (40°C).

Non-condensing environment.

Do not expose to operating temperatures beyond 32-104°F

(0-40°C)

Provide adequate ventilation.

Keep away from equipment, appliances or other sources of

electrical interference.

•

•

•

•

Provide easy access for wiring, viewing, & adjusting the

display screen.

Mount approximately 5 ft. (1.5 m) off the finished floor.

Locate the control near pumps &/or zone valves if possible.

Provide a solid backing to mount the enclosure to. For

example: plywood, studs, etc

Use the conduit knockouts provided on the upper, lower,

back & sides of the enclosure.

•

•

•

•

•

Figure 1

1

2345

Temperature Sensors - Do Not Apply Power

tekmarNet Communication

C3

C2

C0

C1

H70

19

C

75

76

Valve

77

78

79

80

81

82

Pump

Power In

L

N

DHW

Alert

45

46

Auxiliary

43

44

Pump

47

48

P1

Pump

Primary

Primary

49

50

P2

Pump /

Boiler 1

85

86

83

84

20V

11

dc

5V

dc

Out In Out In

In

Vdc

14

+

+

Gnd

15

mA

12

13

+

EMS

16

Out

17

Boil

Sup

18

Com

19

Boil

Ret

Boil

In

20

DHW

21

Com

22

Vent

23

24

25

Boil

1

Out

26

Boil

2

Out

27

Com

Com

28

Com

31

Boil

3

Out

29

Boil

4

Out

30

tN4

32

33

Bus b

tN4

34

35

Bus 1

tN4

36

37

Bus 2

tN4

38

39

Bus 3

Boiler

Boiler

Boiler

Boiler

Flow Proof

1

2

Call

C.A. Proof

3

4

Call

Heat

5

6

Call

DHW

7

8

Call

Setpoint

9

10

Call

40

41

BACnet IP

42

External Flow Proof / Off

External C.A. Proof / Off

Off / Exercise

Setback / Off

51 52

Mod

Boiler 1

53 54

Stage 1

Stage 2

55

56

+

-

Mod

Stage 1

Stage 2

+

-

Mod

Stage 1

Stage 2

+

-

Mod

Stage 1

Stage 2

+

-

57 58

Boiler 2

59

60

61

62 63 64

Boiler 3

65

66

67

68

69

70

Boiler 4

71

72

73

74

tektra 1056-01

For product literature:

www.tekmarControls.com

Disconnect All Power

Before Opening

Designed and

assembled in Canada

Meets Class B: Canadian

ICES & FCC Part 15

Signal wiring must be

rated at least 300 V.

Boiler Control 284

Four tN4, BAS, Four Boiler, DHW & Setpoint

Manual

Override

Home

I

I

Input Power:

115 V (ac) ±10%, 60 Hz, 18 VA

Primary Pump Relays:

230 V (ac), 10 A, 1/2 hp

Boiler & DHW Pumps:

230 V (ac), 5 A, 1/3 hp

Boiler Stage, Auxiliary &

Alert Relays:

230 V (ac), 5 A, 1/6 hp

Calls: 24 V (ac) or Short

I

B

A

Gnd

+

–

–

–

RS485

Flow

Sensor

Pressure

Sensor

WARNING

Valve

Pump /

Boiler 2

Valve

Pump /

Boiler 3

Valve

Pump /

Boiler 4

7

1

/

8”

(181 mm)

Ground

Screws

10

3

/

16”

(259 mm)

Screw hole

Dimensions

Figure 2

Custom Panel

or Electrical Box

Wall or Panel Door

To avoid serious personal injury and damage to the equipment:

It is the installers responsibility to ensure that this control

is safely installed according to all applicable codes and

standards.

Improper installation and operation of this control could result

in damage to the equipment and possibly even personal

injury or death.

This electronic control is not intended for use as a primary

limit control. Other controls that are intended and certified

as safety limits must be placed into the control circuit.

Do not attempt to service the control. There are no user

serviceable parts inside the control. Attempting to do so

voids warranty.

•

•

•

•

Important Safety Information

It is your responsibility to ensure that this control is safely installed according to all applicable codes and standards.

tekmar is not responsible for damages resulting from improper installation and/or maintenance.

Read Manual and all product labels BEFORE

using the equipment. Do not use unless

you know the safe and proper operation

of this equipment.

Keep this Manual available for easy access

by all users.

Replacement Manuals are available at

tekmarControls.com

•

•

•

Disconnect all power before opening the

control.

•