Operating hours counter for maintenance intervals – Rockwell Automation 1760-xxxx Pico Controller User Manual User Manual

Page 165

Publication 1760-UM001D-EN-P - September 2005

Retention 7-15

Operating Hours Counter for Maintenance Intervals

Task 2

Every 1000 hours, the system or machine must undergo preventive

maintenance. Filters and transmission oil must be changed and the

bearings must be lubricated.

Contacts and relays used:

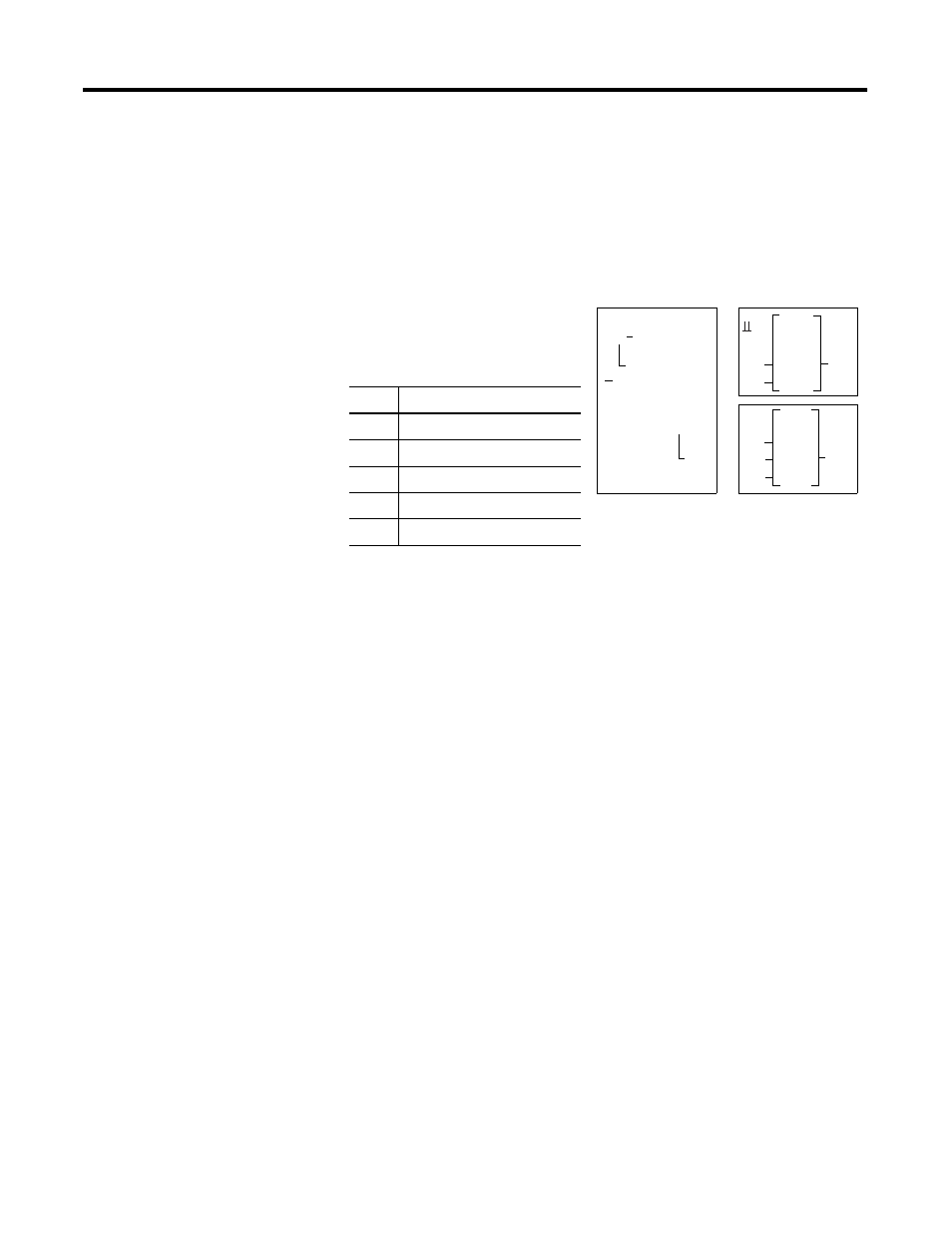

Function of the Pico circuit diagram:

T8 provides the clock pulse. When a time of t = 30 minutes is

selected, the counting period amounts to 2 x t = 60 min. Every hour,

one pulse is counted. The up counter C8 triggers a warning light at

1000 by means of Q4.

For the clock pulse to be correct when there is a power outage, T8

must be retentive.

M16 prevents C8 from accidentally receiving a counter pulse when the

power is turned back on if there was a power outage during the

counting period.

Both M16 and C8 must retain their actual values at power outage so

that the 1000 hours of operating with interruptions in the power

supply can be counted.

I1 (for example, a key-operated switch) is used to reset the counter.

Coil

Function

T8

Clock pulse

M16

Block double pulse

Q4

Warning light, 1000 h reached

C8

Up counter

I1

Reset

-----------TT8

T8-M16-----CC8

-------SM16

T8--------RM16

C8---------{Q4

I1---------RC8

RT8

18:38

30.00

TRG

RES

T8

+

{

{

M:S

1000

DIR

CNT

RES

C8

+

0107

{

{

Circuit Diagram:

Parameters entered: