Plc ladder logic example – Rockwell Automation 1203-GK5 DeviceNet Communications Module FRN 1.xxx-3.xxx User Manual

Page 64

5-4

Creating a Ladder Logic Program

PLC Ladder Logic Example

In the following example, a PLC-5, 1771-SDN DeviceNet scanner,

and 1203-GK5 module (or 1336-GM5 board) are used to control a

1305, 1336 PLUS, or 1336 PLUS II drive.

The example program shows how to obtain status information from

the drive and how to control it (e.g., starting the drive, stopping the

drive, jogging the drive, sending reference, and clearing faults). When

you understand this example, you should be able to customize the

program to fit you application needs.

The example assumes that there is an operator’s station wired to an

I/O module in slot zero of module group zero of rack zero.

Important: You may want to verify a device has not failed using

word 0 of block transfer 62 before sending control data. If a device

has failed, use block transfer 52 to find out which device failed. Refer

to the 1771-SDN DeviceNet Scanner Module Manual, Publication

1771-5.14, for more information.

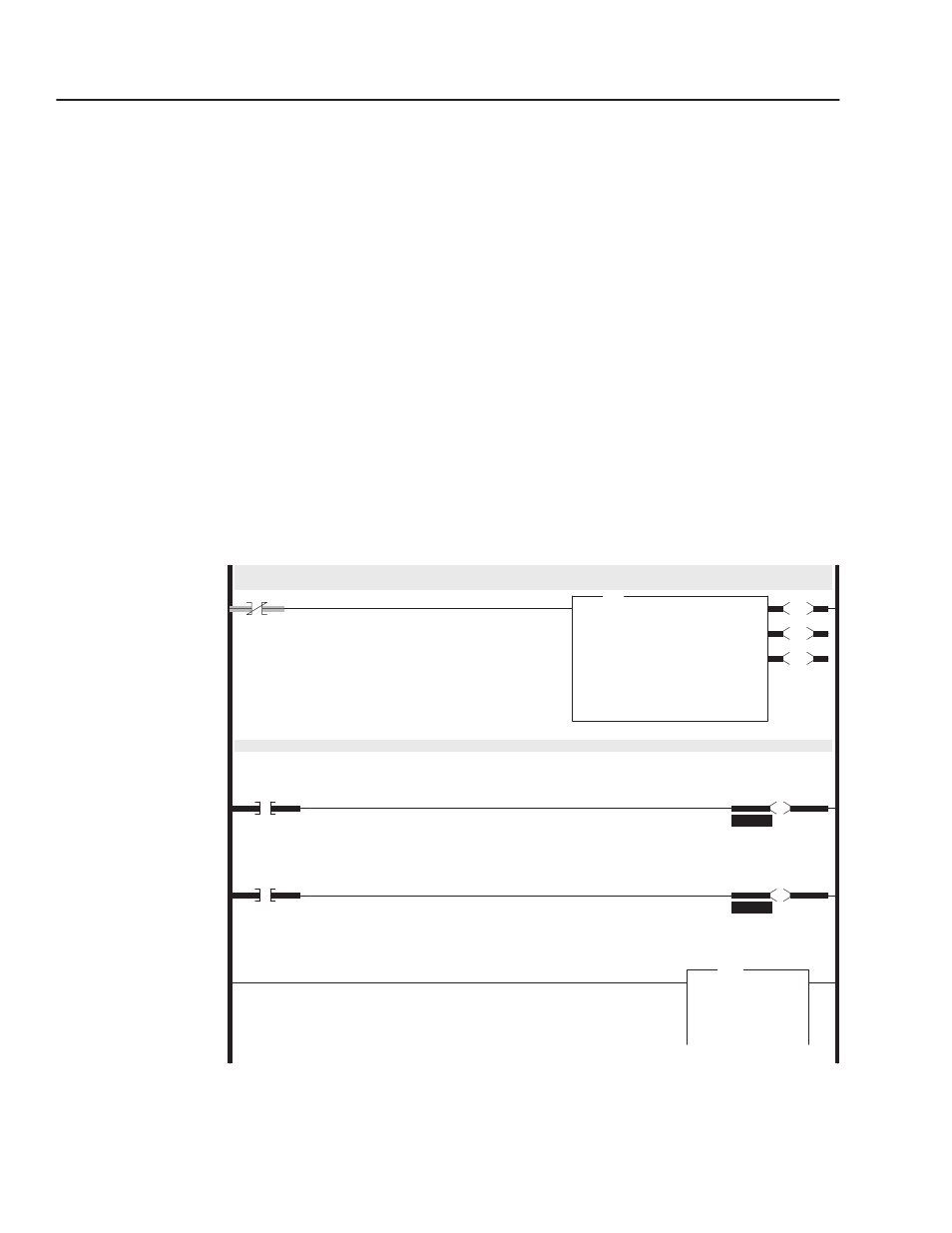

Figure 5.2

Example PLC Ladder Logic Program

The scanner gathers drive status information via DeviceNet.

The Block Transfer Read in this rung then moves the drive status data from the scanner to the PLC’s N9 data file.

0000

BT20:0

EN

EN

DN

ER

BTR

Block Transfer Read

Module Type Generic Block Transfer

Rack

000

Group

0

Module

0

Control Block

BT20:0

Data File

N9:0

Length

62

Continuous

No

BTR

Rungs 0001 through 0003 move the drive status from the Block Transfer Read data file to an operator display.

0001

N9:1

1

1305 Drive

RUNNING

Status Bit

O:000

10

Operator Display

Drive Running

Status Bit

0002

N9:1

7

1305 Drive

FAULTED

Status Bit

O:000

11

Operator Display

Drive Faulted

Status Bit

0003

MOV

Move

Source

N9:2

0<

Dest

N21:1

0<

MOV

Operator Display

Drive Feedback

Status Word