Fault history sub screen – TCI HGA Manual User Manual

Page 88

88

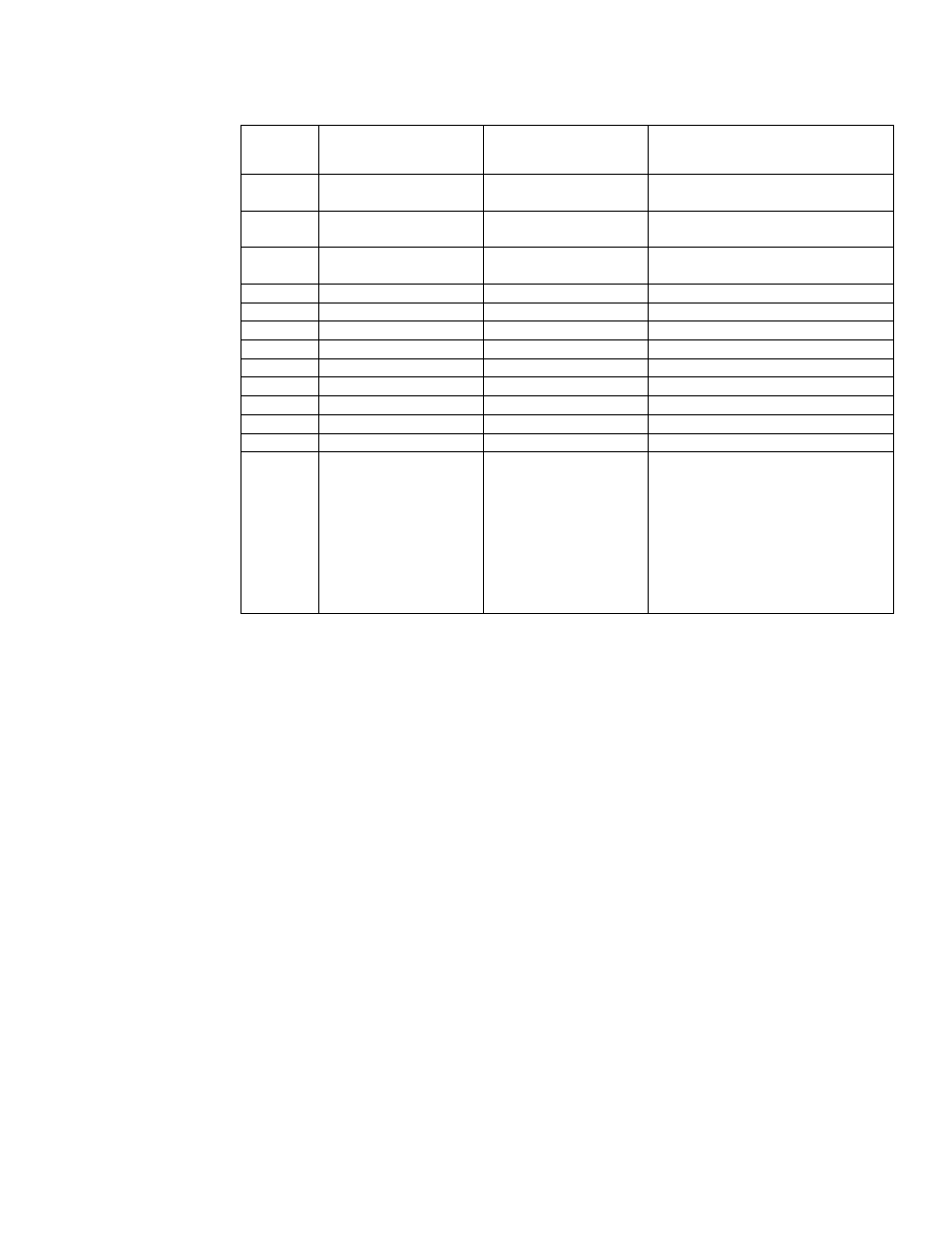

Table 7.12 – Fault Codes

Fault

Code

Critical or

Non-critical Fault

Auto or Manual

Reset

Fault Description

10

Critical

Manual*

Desat (IGBT Gate Driver) Fault

Phase A

20

Critical

Manual*

Desat (IGBT Gate Driver) Fault

Phase B

30

Critical

Manual*

Desat (IGBT Gate Driver) Fault

Phase C

1000

Non-critical

Auto

DC Bus Overvoltage

1250

Non-critical

Auto

DC Bus Undervoltage

3000

Non-critical

Auto

Overcurrent on Phase A

3010

Non-critical

Auto

Overcurrent on Phase B

3020

Non-critical

Auto

Overcurrent on Phase C

4000

Critical

Power Cycle**

Overtemperature

4250

Non-critical

Auto

Undertemperature

7000

Non-critical

Auto

Calibration Fault

7010

Non-critical

Auto

Communications Fault

Unit N

Faulted

Non-critical

Auto

Fault location indication. Fault

originated in Unit N where N is in

the range 1 to 8. For factory

configured parallel systems the

unit numbers are sequential

ordered from left to right when

looking at the front of the

system. Unit 1 is the left most

unit in the system.

*Critical faults flagged with a manual reset require a HMI stop button or run/stop switch stop command at the

unit to clear.

**Critical faults flagged with a power cycle reset require a manual on/off power cycle of the unit to clear.

Fault History Sub Screen

The “Fault History” sub screen (See Figure 7.12) contains up to 120 entries that mark the onset and clearing

of system faults. At the onset of a fault condition an entry will be generated in the fault history marked with

an “O” on the left side of the fault entry. When a fault clears an entry will be generated in the fault history

marked with an “X” on the left side of the fault entry.

The Fault History persists through power on/off cycles. In the event the fault history log exceeds the max

number of 120 entries the oldest entry will be overwritten by new entries.