Connection diagram – TCI HGA Manual User Manual

Page 31

31

Table 4.1b – Power Terminal Wire Size (without breaker) Capacity Range and Tightening Torque

Caution

Use copper wire that is appropriate for the voltage and current rating of the equipment. The wire

selection must conform to the requirements of the National Electrical Code and/or other applicable

electrical codes.

Use wire with an insulation temperature rating of 75°C or higher.

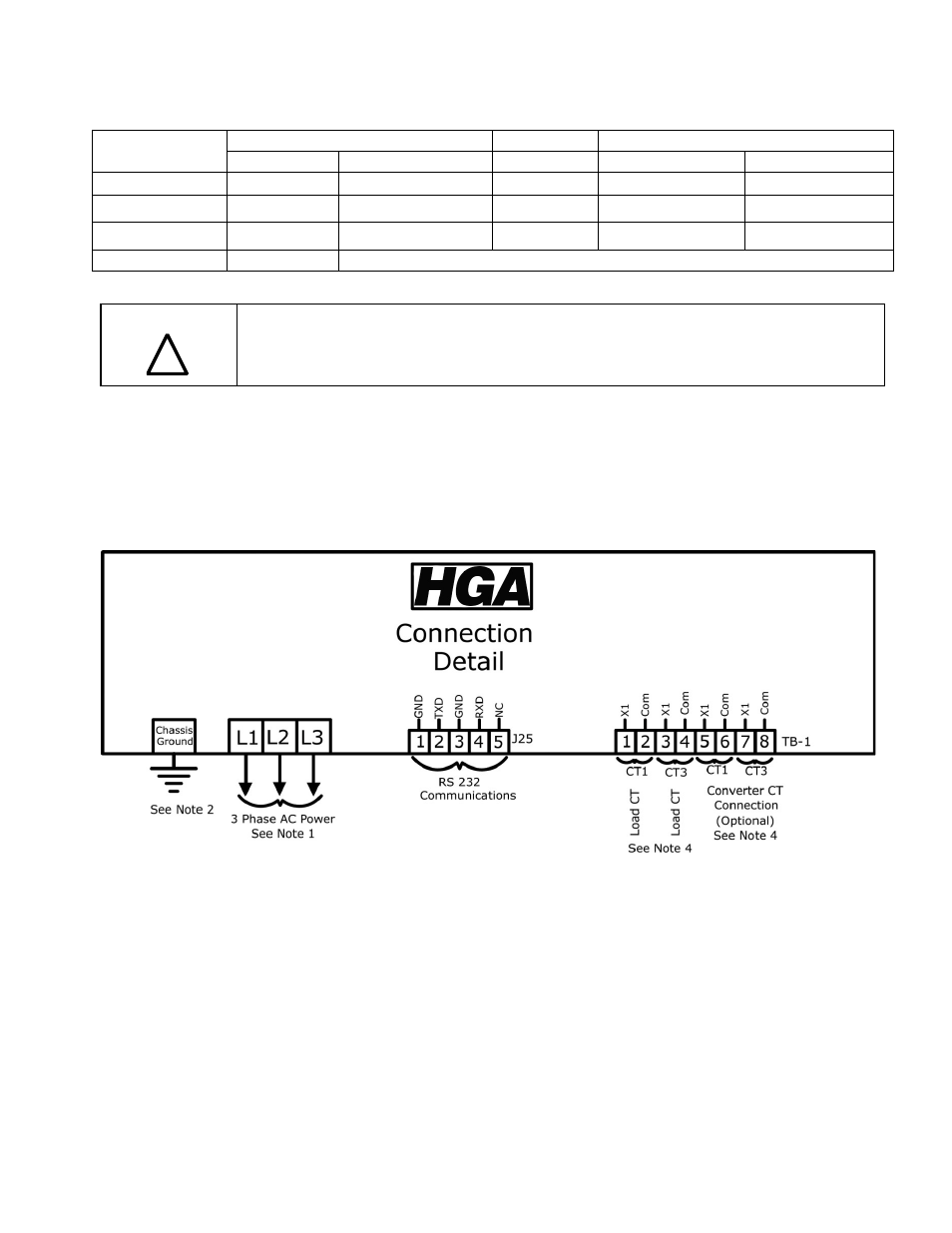

Connection Diagram

Figure 4.3 shows the typical wiring connections between the models of the HGA and the load. Refer

to the drawings furnished with the unit for more specific information.

• The input 3-phase AC voltage source must be connected in a positive ABC phase rotation

from L1-L2-L3 for correct unit operation.

Figure 4.3 – Typical Load Connection Diagram

Notes:

1.) Wiring should be 75°C or higher insulated copper, with the appropriate voltage and current rating.

2.) Chassis ground must be connected to the ground of the premises wiring system, in accordance

with NEC and local codes. Connection must be made using a wire conductor.

3.) Terminal TB-I & J25 wire range is 30-12 AWG, tightening torque is 4.4 IN-LB (0.5 NM).

4.) Operating current transformers with the secondary winding open can result in a high voltage

across the secondary terminals which may be dangerous to personnel or equipment.

Chassis Size

Ground Lug

Power Terminals

Wire Size

Torque In-lbs (Nm)

Breaker IC

Wire Size

Torque In-lbs (Nm)

39 to 100 Amp

14 AWG – 2/0

120 (13.6)

25 to 100 kA

14 – 2/0 AWG

180 (20.3)

150 to 200 Amp

14 AWG – 2/0

120 (13.6)

25 to 100 kA

6 AWG – 350 MCM

274 (31)

150 to 200 Amp

14 AWG – 2/0

120 (13.6)

None

6 AWG – 350 MCM

274 (31)

Control Terminals

Wire Size 28 to 14 AWG Torque 4.4 in-lb (0.5 Nm)

!