Converter inspection – TCI HGA Manual User Manual

Page 54

54

Converter Inspection

• Verify that power has been removed from converter, and 5 minutes has passed before

inspection.

• Remove plastic cover from over converter section.

• Visually check the circuit boards for debris; contamination; overheated traces; burnt

circuit board; overheated, cracked, or broken components; corrosion; and poor solder

joints.

• Check all wires and terminals connected to the circuit boards.

• Check the four electrolytic capacitors for bulges, ruptures, popped vent plugs,

discoloration, or leakage.

• Check the power semiconductors mounted to heat-sink for cracked cases, ruptures,

debris, arcing, and burning.

• Check for any loose connections if no apparent damage is found to the power

semiconductors.

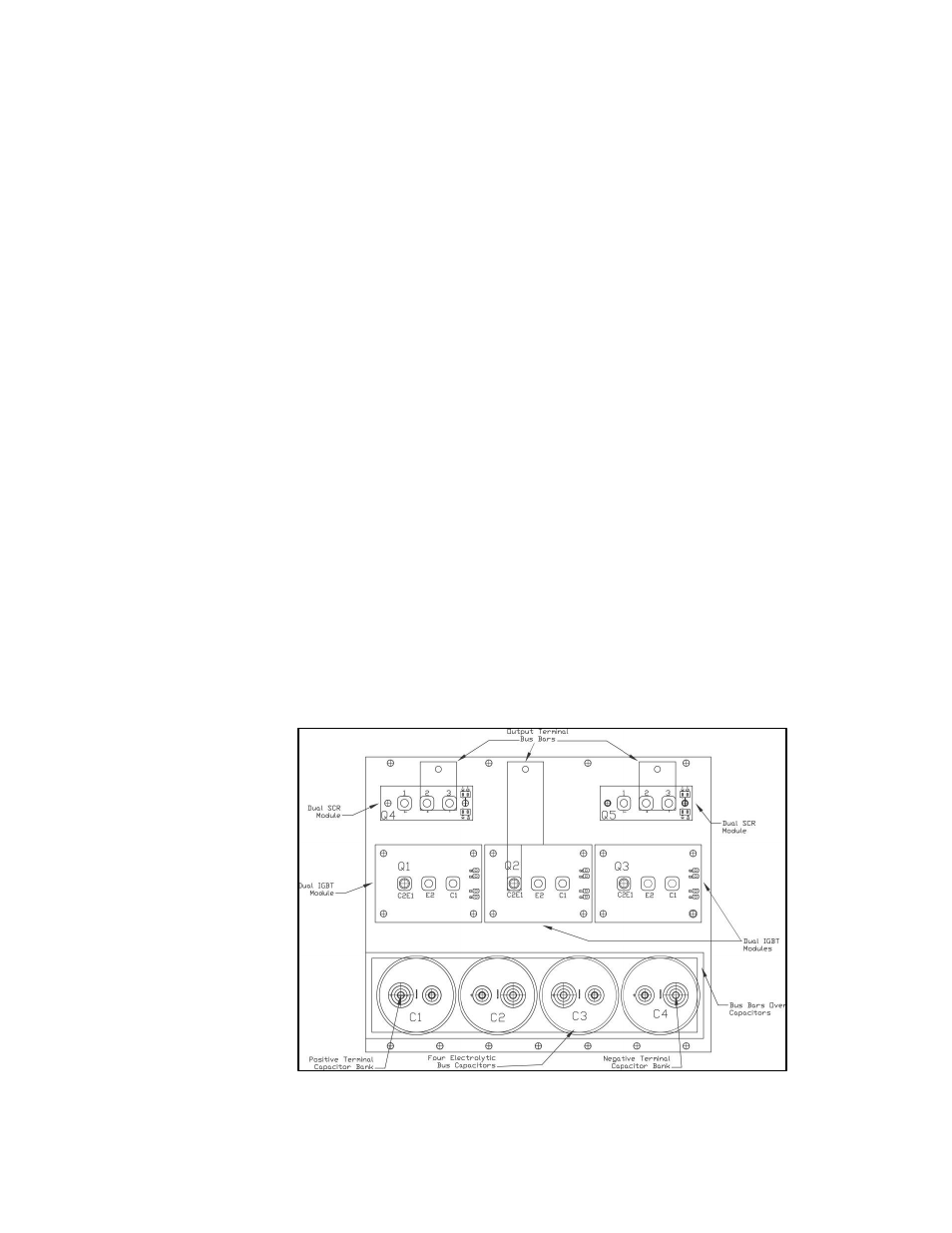

• Measure resistance of power semiconductors using a multimeter set on the diode check

setting, see Figure 5.2.

Look for opens, ∞,

or dead short readings. With the red lead of

your meter connected to the far right negative terminal of the capacitor bank, measure

with the black lead of the meter to each of the three output terminals (bus bars), the

reading should be approximately 0.35Ω. Reverse the meter leads and repeat measuring to

each terminal. This time a low reading will be present which will continue to increase;

this is an indication of a capacitor charging. Next connect the black meter lead to the

“positive capacitor terminal” and again measure to each of the output terminals with the

other lead; the reading should be approximately 0.35

Ω

.

Reverse the meter leads and

repeat measuring to each terminal. Again it will be a low reading which will continue to

increase. If the readings are as described, in all likelihood the power semiconductors are

good. If any readings are opens or dead shorts it will be an indication that something is

bad in the power section. Do not reapply power if you are not sure the IGBT’s are good.

Figure 5.2 – 39, 45, 78, 90, 100, and 200 Amp Power Component Layout