Adjusting outer skid shoe, 2auto header height control, Auto header height control – MacDon FD75 OM User Manual

Page 70: Danger, 2 auto header height control

6.

Reinsert pin (B), engage in frame, and secure with

lynch pin (A).

7.

Check that all of the skid shoes are adjusted to the

same position.

8.

Adjust header angle to desired working position using

the machine’s header angle controls. If angle is not

critical, set it to mid-position.

9.

Check header float. Refer to

Figure 4.32: Inner Skid Shoe

Adjusting Outer Skid Shoe

1.

Fully raise the stabilizer wheels or slow speed transport wheels if installed. Refer to:

•

Adjusting Stabilizer Wheels, page 53

or

•

Adjusting Stabilizer/Slow Speed Transport Wheels, page 52

DANGER

To avoid bodily injury or death from unexpected start-up or fall of raised machine, always stop engine,

remove key, and engage safety props before going under header for any reason. Refer to the combine

operator’s manual for instructions regarding the proper use and storage of header safety props.

2.

Fully raise header, engage safety props, shut off engine, and remove key.

3.

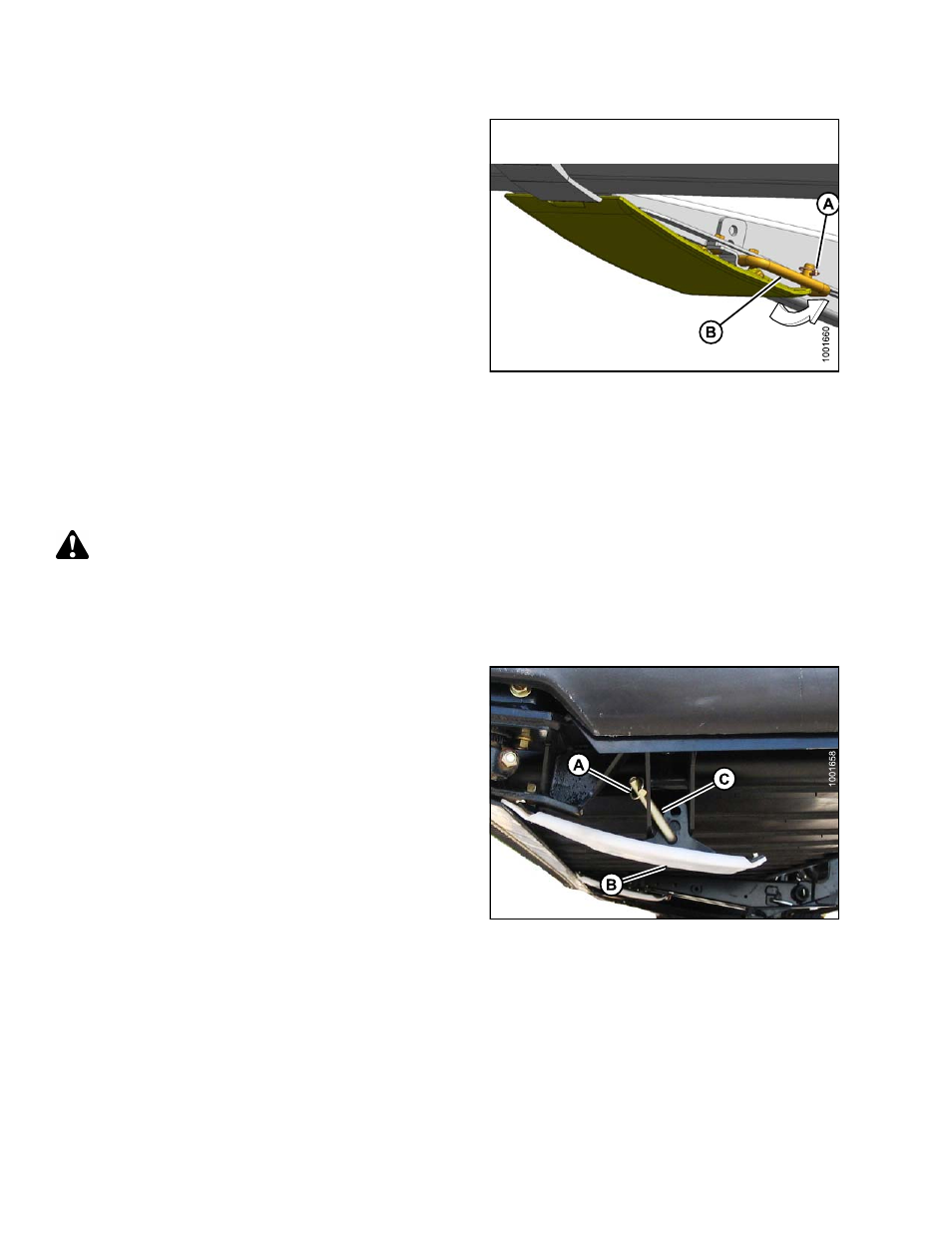

Remove lynch pin (A) at each skid shoe (B).

4.

Hold shoe and remove pin (C) by disengaging frame

and then pulling away from shoe.

5.

Raise or lower skid shoe to desired position using holes

in support as a guide.

6.

Reinstall pin (C), engage in frame, and secure with

lynch pin (A).

7.

Check

that

skid

shoes

are

adjusted

to

the

same position.

8.

Check header float. Refer to

Figure 4.33: Outer Skid Shoe

4.7.2

Auto Header Height Control

MacDon’s Auto Header Height feature works in conjunction with the Auto Header Height Control option available

on certain combine models.

A sensor is installed in the float indicator box (A) on the CA25 Combine Adapter. This sensor sends a signal to

the combine to allow it to maintain a consistent cutting height, and optimum adapter float as the header follows

ground contours.

169894

56

Revision A