6draper roller maintenance, Inspecting draper roller bearing, Draper roller maintenance – MacDon FD75 OM User Manual

Page 354: 6 draper roller maintenance

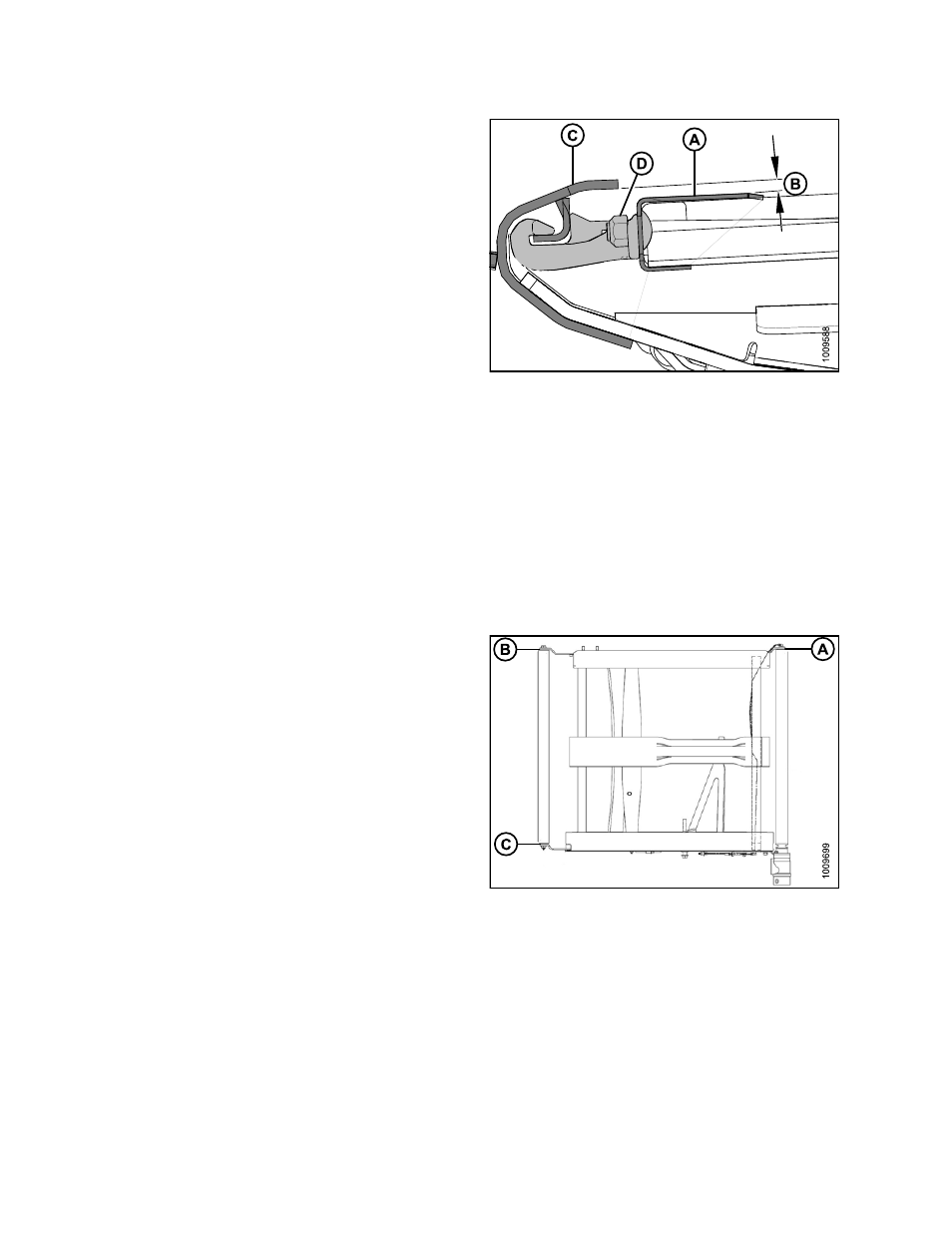

5.

Set deck (A) to 5/16–3/8 in.

(8–9 mm) below the

cutterbar (C) to create a seal.

6.

Tighten deck support hardware (D).

7.

Check dimension (B) again it should be set to

5/16–3/8 in. (8–9 mm).

8.

Tension draper. Refer to

.

Figure 6.172: Deck Support

6.11.6

Draper Roller Maintenance

The draper rollers have non-greaseable bearings. The external seal should be checked every 200 hours (and

more frequently in sandy conditions) to obtain the maximum bearing life.

Inspecting Draper Roller Bearing

Procedure to inspect draper roller bearings.

1.

If a bad bearing is suspected in one of the

draper rollers, a quick way to check is using a

infrared thermometer.

2.

Engage header and run for approximately 3 minutes.

3.

Check

the

temperature

each

of

the

roller

arms (A), (B), (C) on each deck.

They should not

exceed 80°F (27°C) above ambient temperature.

Figure 6.173: Roller Arms

169894

340

Revision A