Troubleshooting and fault elimination, Error message – Lenze 931E/K Small Drives Control User Manual

Page 127

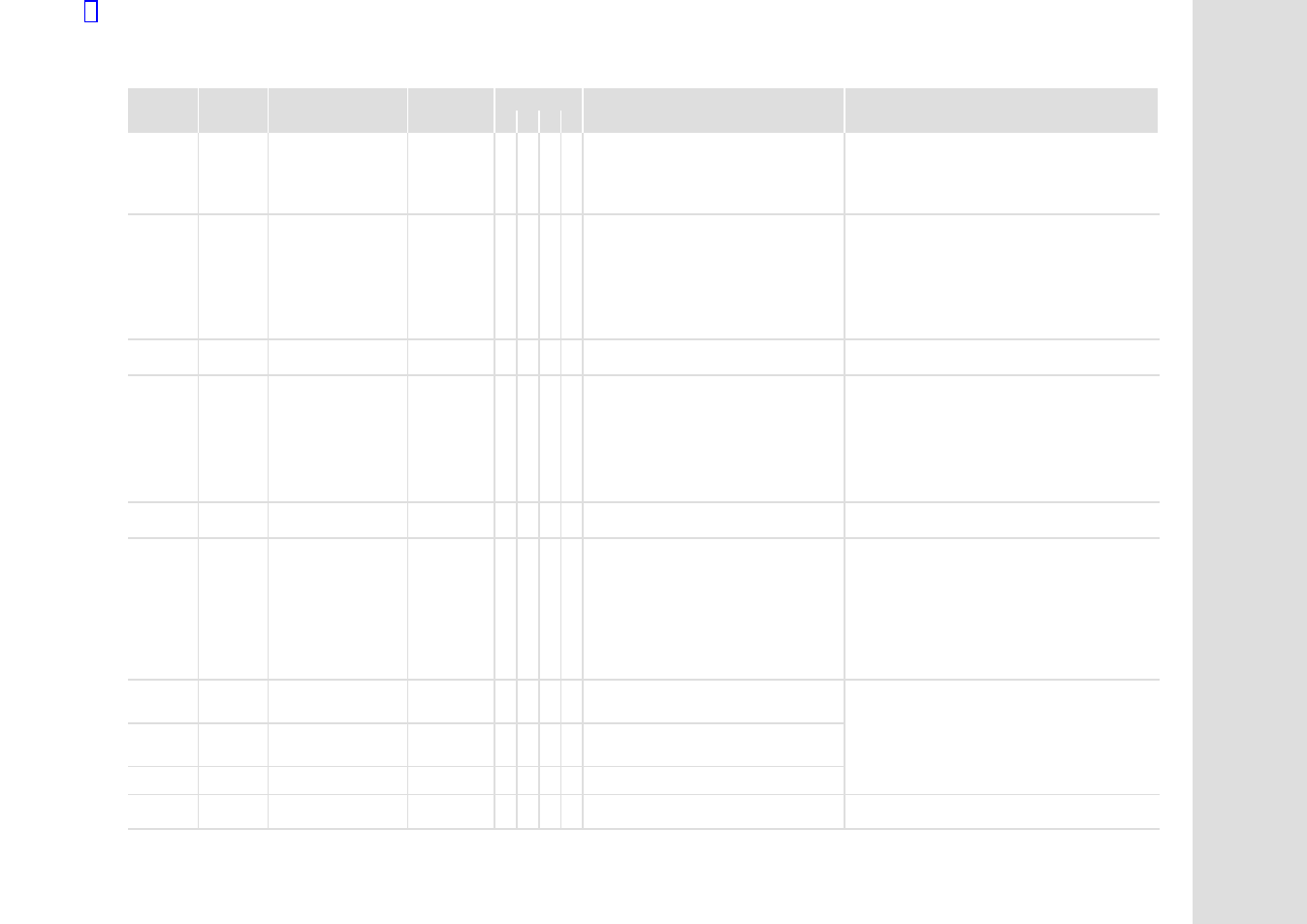

Troubleshooting

and fault elimination

Error message

9

l

127

SW−HB

13.0002−EN 4.1

Remedy

Cause

Response

Activation

time

Meaning

CAN error

code

Error No.

Remedy

Cause

O

W

H

A

Activation

time

Meaning

CAN error

code

Error No.

10

5114

12V−electronic supply

error

< 5 msec

þ −

−

−

l

Error may occur as a result of a defective

angle encoder / SINCOS encoder, a

wiring error of X2 or a supply voltage

drop

l

Voltage supply

l

Electronics error in 931E/K, cannot be removed by

the user. Send servo positioning controller to your

Lenze representative.

11

5112

24V−electronic supply

error

< 5 msec

þ −

−

−

l

24 V logic supply too high or too low

l

Load capacity of 24 V logic supply is too

low, e.g. when activating the holding

brake

l

Holding brake or X3 wiring error, or

overload of the brake output due to an

excessive current consumption of the

brake.

l

Electronics error in 931E/K, cannot be removed by

the user. Send servo positioning controller to your

Lenze representative.

13

5210

Offset current

measurement error

< 5 msec

þ −

−

−

Send servo positioning controller to your Lenze

representative.

14

2320

DC bus / power stage

overcurrent

< 10

μs

þ −

−

−

l

Defective motor, e.g. winding overloaded

or charred, short circuit between

winding and housing

l

Cable short circuit between two phases

or phase and shield

l

Insulation of motor phase connections

l

931E/K fault (power stage defective or

insulation error − insulating foil)

15

3220

DC bus undervoltage

< 1 ms

ю ю ю ¨ DC bus undervoltage

l

Check DC bus voltage, adapt undervoltage

tripping threshold, if necessary.

16

3210

DC bus overvoltage

< 1 ms

þ −

−

−

DC bus overvoltage > 70 V

l

Check correct functioning of power supply unit

and if the supply voltage for the power stage is

within the permissible range

(19.2 V DC ... 57.6 V DC).

l

Reduce slope of deceleration ramp.

l

Connect an external brake resistor to X2.

l

Check if the overvoltage has been caused by other

devices connected to the DC supply of the power

stage.

19

2312

I

2

t−error of motor (I

2

t

at 100%)

< 100 ms

ю ю ю ¨ I

2

t−error of motor

l

Adapt i

2

t−time of motor.

l

Carry out a resolver position adjustment.

l

Check the selected motor data.

l

Optimise the controller setting.

l

Adapt the traversing profile (e.g. adapt the

acceleration ramps).

l

Reduce the load torque of the motor.

20

2311

I

2

t−error of controller

(I

2

t at 100%)

< 100 ms

ю ю ю ¨ I

2

t−error of controller

26

2380

I

2

t at 80%

< 100 ms

ю ю ю ¨ I

2

t−error

27

4380

Motor temperature

5

°C below maximum

< 100 ms

ю ю ю ¨

Check power dimensioning of the drive system.