7 shafts do not rotate, Shafts do not rotate, Shafts do not rotate ( 150) – Lenze EtherCAT control technology User Manual

Page 150: Control technology | ethercat communication manual

Control technology | EtherCAT communication manual

Diagnostics

Error scenarios

150

L

DMS 3.1 EN 01/2011 TD17

11.6.7

Shafts do not rotate

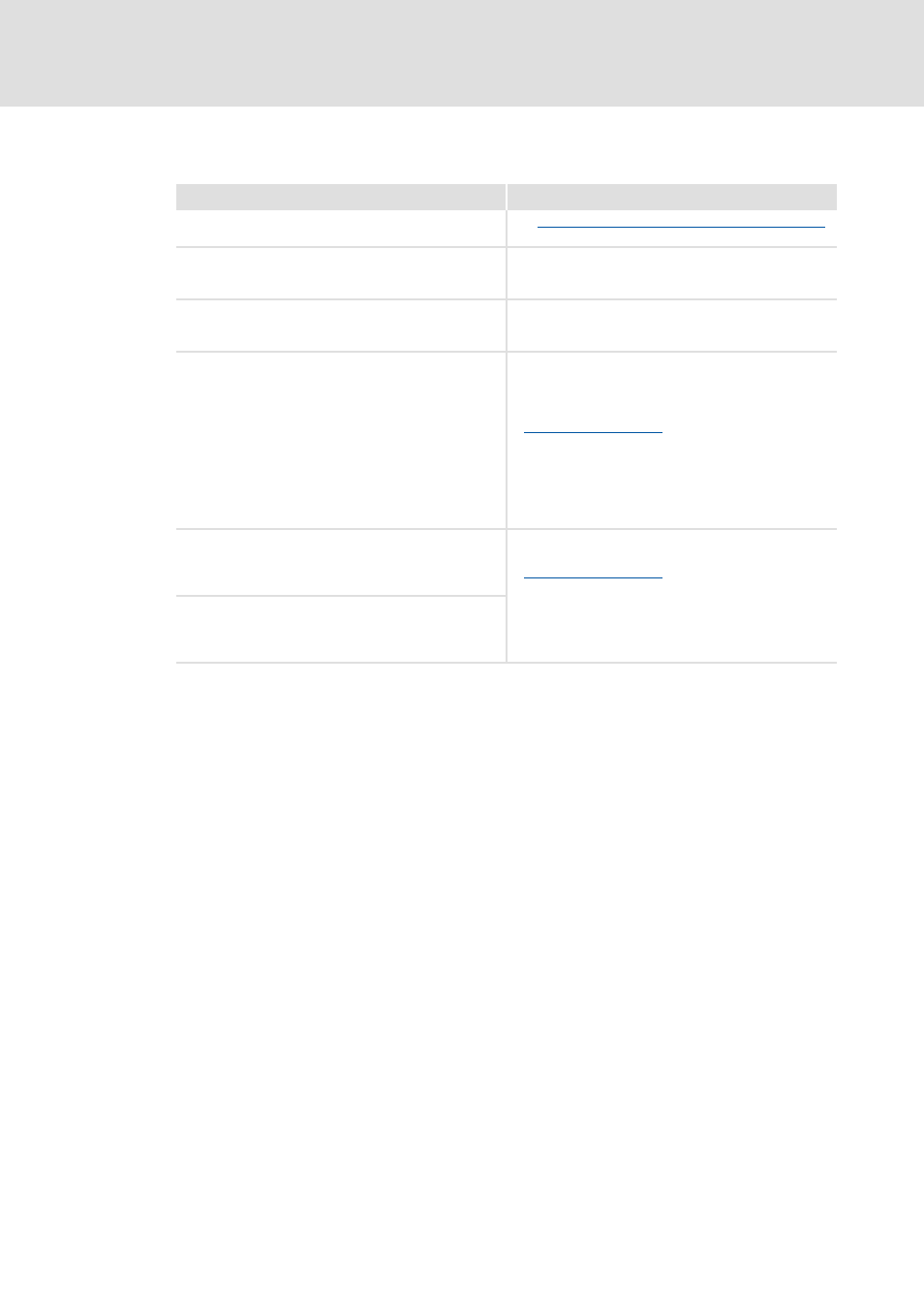

Causes

Remedies

The EtherCAT bus could not be set to the Operational

state

See:

EtherCAT bus does not enter the Operational state

The current master configuration has not been loaded on

the control system or imported into the »PLC Designer«

project.

Load the current master configuration onto the control

system or import it into the »PLC Designer« project.

The process image on the EtherCAT bus does not comply

with the one in the control.

Correct the current master configuration and load it onto

the control system or import it into the »PLC Designer«

project.

In the EtherCAT Configurator, the increments per

revolution are not set for the SoftMotion scaling/

mapping.

Check the following settings and correct them if

required:

• Gearbox ratio in the »PLC Designer« project

• Mapping settings in the master configuration

• During start-up of the PLC, the complete

configuration/PDO mapping is written into the

EtherCAT slaves. Mapping entries, e.g. from the

»Engineer«, are not overwritten.

• Tip: In case of the Servo Drive 9400 HighLine Cia402,

65536 increments per revolution are correct.

The »PLC Designer« project does not access the EtherCAT

inputs and outputs via symbolic addresses, but via

logical addresses. This causes problems if the bus

structure, the PDO selection, etc. have been changed.

Check and correct the mapping settings in the master

configuration.

During start-up of the PLC, the complete configuration/

PDO mapping is written into the EtherCAT slaves.

Mapping entries, e.g. from the »Engineer«, are not

overwritten.

For the Servo Drive 9400 HighLine, the ports are not

mapped correctly or not mapped at all in the »Engineer«,

and parameters have therefore not been transferred to

the device.