2 event traces, 3 operation and visualisation – JUMO 706030 LOGOPRINT 500 Printing Recorder Operating Manual User Manual

Page 30

3 Operation and visualisation

30

These minimum and maximum values are printed when peak value recording

is activated. One advantage of the peak value recording is that at least an im-

pression of the measurement trace on the chart can be gained, even at slow

chart speeds and after text printing in the “Interrupt measurement trace”

mode.

The peak value recording can be switched on and off for each channel by us-

ing the parameter Configuration level 1

Î

Peak value recording.

Colour

assignment

The colours which are used to print the traces can be set with the aid of the

setup program.

In the basic status, for a 3-channel recorder, the colours violet, red and black

are assigned to the channels 1 — 3.

When using a 6-channel recorder, the colours green, blue and brown are also

used, for the additional channels 4 — 6.

3.4.2

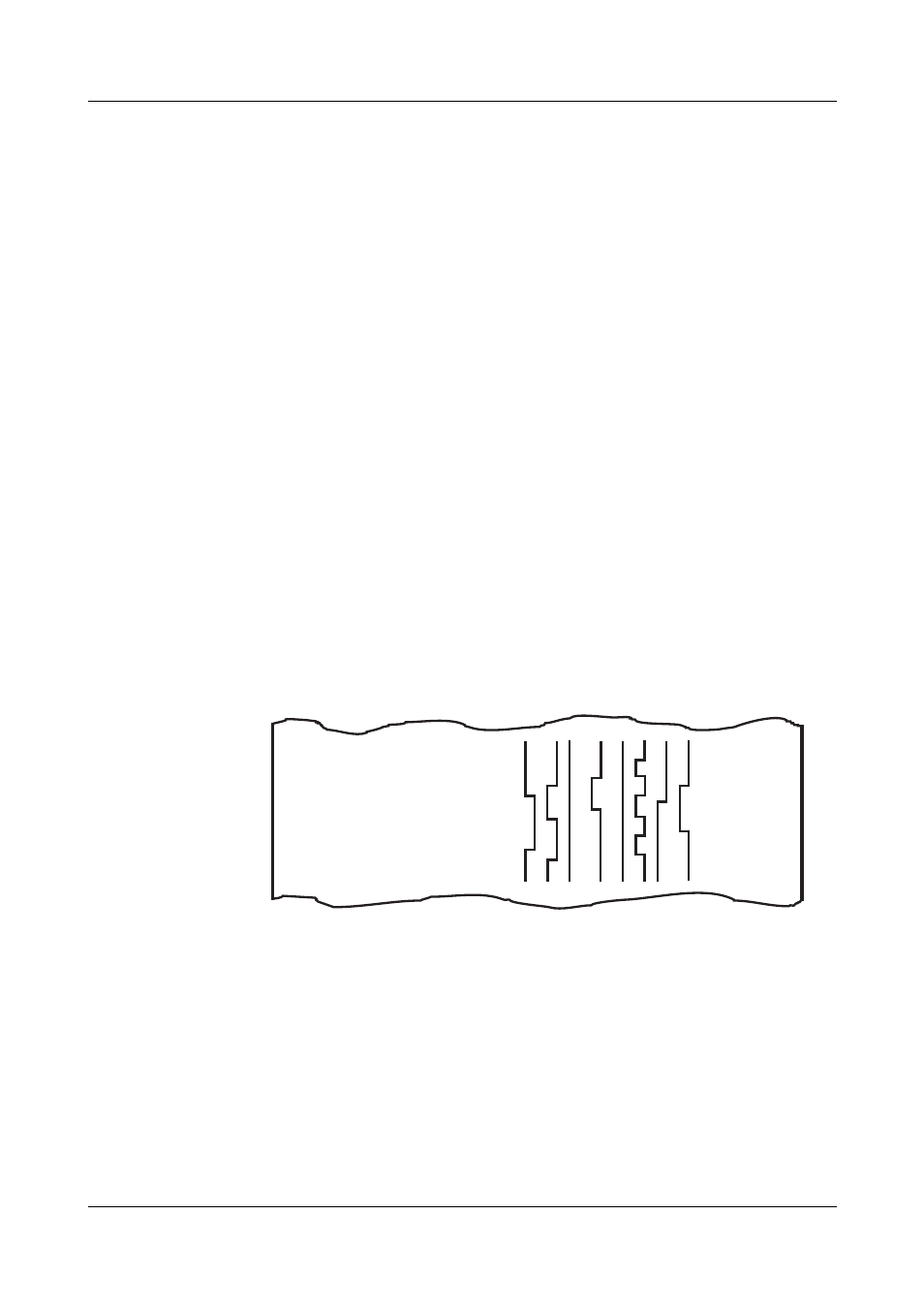

Event traces

In addition to the measurement traces, the printing recorder offers the possi-

bility of recording up to 8 event traces. The sources for the events can be the

limit comparators as well as the logic inputs (extra code).

The source selection and trace selection are made by the parameter Configu-

ration level 3

Î

Event traces.

The setup program can be used to select the start position of the event traces

on the chart paper, between 0 and 100%.

If not all the event traces are selected, then a gap will appear at the corre-

sponding positions. This means that every trace has the same spacing from

the defined start position.

Colour

assignment

In the 6-channel version, the colours violet, red, black, green, blue, brown, vio-

let and red are assigned to the event traces 1 — 8. In the 3-channel version

the colours green, blue, brown are replaced by violet, red, black.

The colours can be changed with the aid of the setup program.