11 fault-finding – JUMO 706030 LOGOPRINT 500 Printing Recorder Operating Manual User Manual

Page 100

11 Fault-finding

100

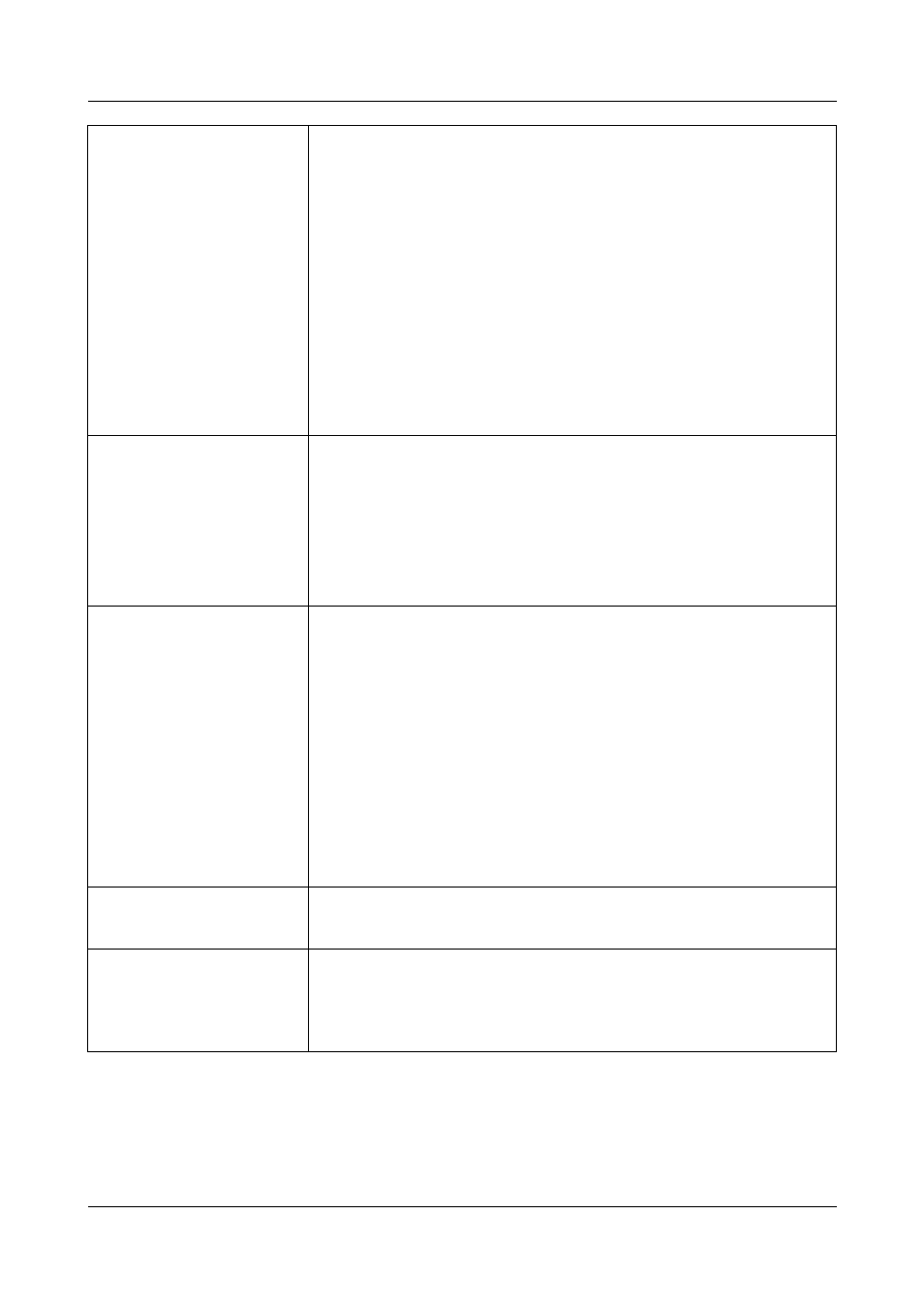

Chart paper is not moving

- The chart cassette has not been fitted correctly

vSection 9.2 “Removing and replacing the chart cassette”

- The take-up roll has not properly engaged with the

chart cassette

vSection 9.2.1 “Changing the roll chart”

- The chart speed has been programmed to 0mm/h

vSection 4.2 “Table of the configuration parameters”

- The paper perforation is not running correctly over the paper-

feed sprocket

- The tear-off edge is not properly engaged

- The printing recorder is in the stop status

Measurements are not

recorded

- Check that the connection terminals are tightened properly

- Check the supply

- Check the input configuration (measurement range)

- Check the transducers and their leads, measure them if

appropriate

- The plot status may be switched off

Relay does not switch,

although limit is exceeded

- The signal inputs are not wired up according to the connection

diagram

- The recorder and the external relay module ER8

are not connected together properly

- The limit differential (hysteresis) has been ignored

- The relay status is “OFF”

- A wrong signal is being compared against a limit

- A signal input is in the “Out of Range” condition, and the re-

sponse of the limit comparators to a probe break (Configuration

level 2 ➔ Limit comparator ➔ Probe break) has been configured

as “constant”

No programming

possible

- A wrong code number has been entered

- The code number has been changed

No communication

with the setup program

- The setup connector is not properly plugged in

- The printing recorder is already being configured by using the

keys: leave the parameter and configuration levels by pressing

the

e key