Figure 6.3: sm75, microdot( connector – INFICON STM-100/MF Thin Film Deposition Monitor User Manual

Page 75

from the 6" BNC cable, and remove the sensor cover and sensing crystal from

the sensing head. Measure the resistance from one of the center push spring

contacts inside the sensor unit to the center conductor of the cable normally

connected to the oscillator. The reading should be less than 0.20

Ω. The

center conductor to the cable shield should be open (greater than 30 M

Ω) with

respect to the outside ground shield of the cable. This check will verify all the

connections from the sensor, the InVac cable, the vacuum feedthrough, and

the BNC cable.

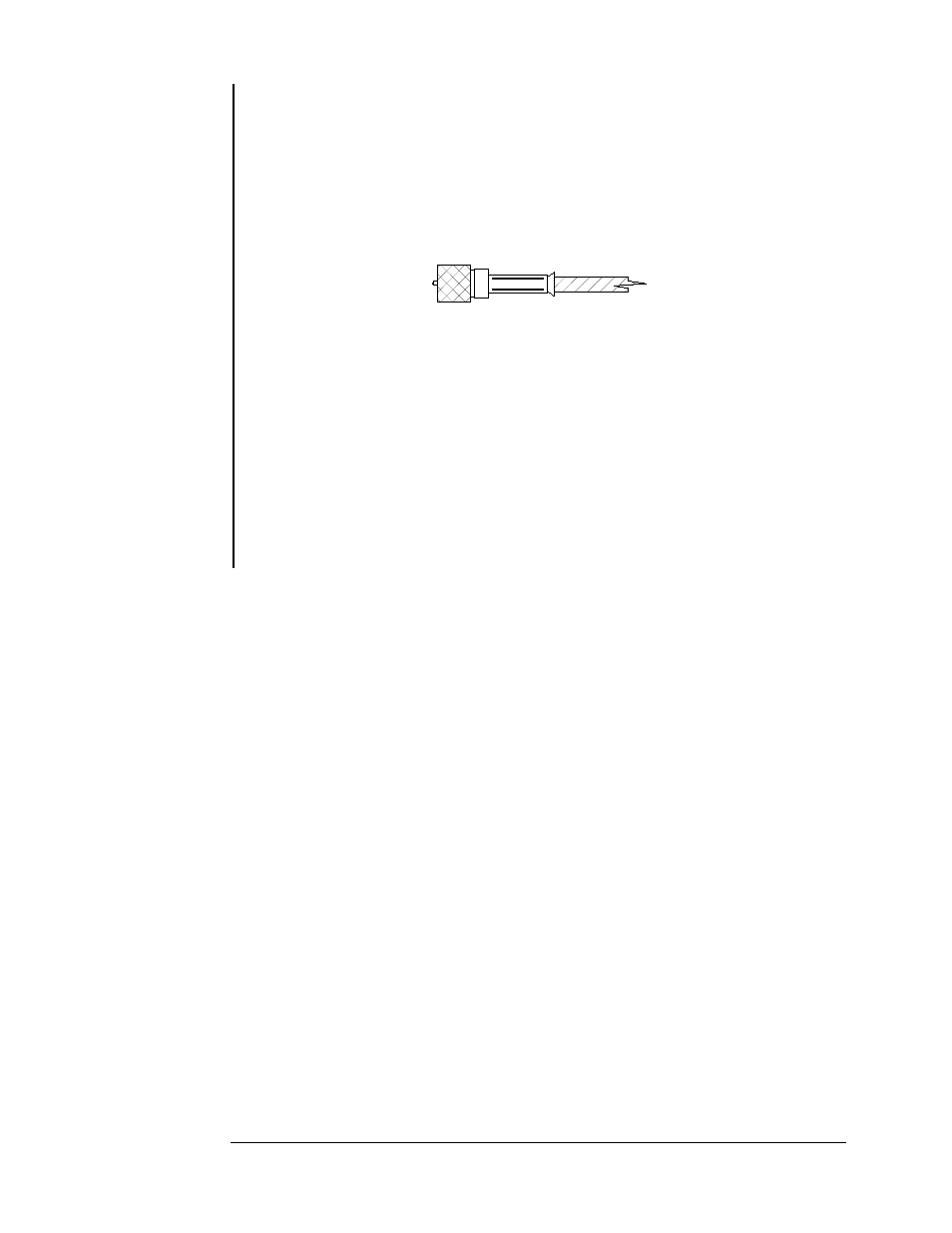

Figure 6.3: SM75, MicroDot

Connector.

If the reading from the continuity test is not as stated, disconnect one part

of the chain and repeat the test. Repeat this last step until the bad connection

is isolated. From experience, most often when a problem occurs it has been

found that the SM75, MicroDot

, connectors on the InVac cable are not

connected securely to the sensor or the feed through. If this is not true then

the cable should be replaced. Also the center pin on the InVac cable can

become damaged and not make contact with the mating connector, Refer to

Figure 6.3. The center pin of the connector should extend slightly beyond the

end of threaded ferrule. If the pin is damaged the cable should be replaced.

MAINTENANCE

Page 6 - 4