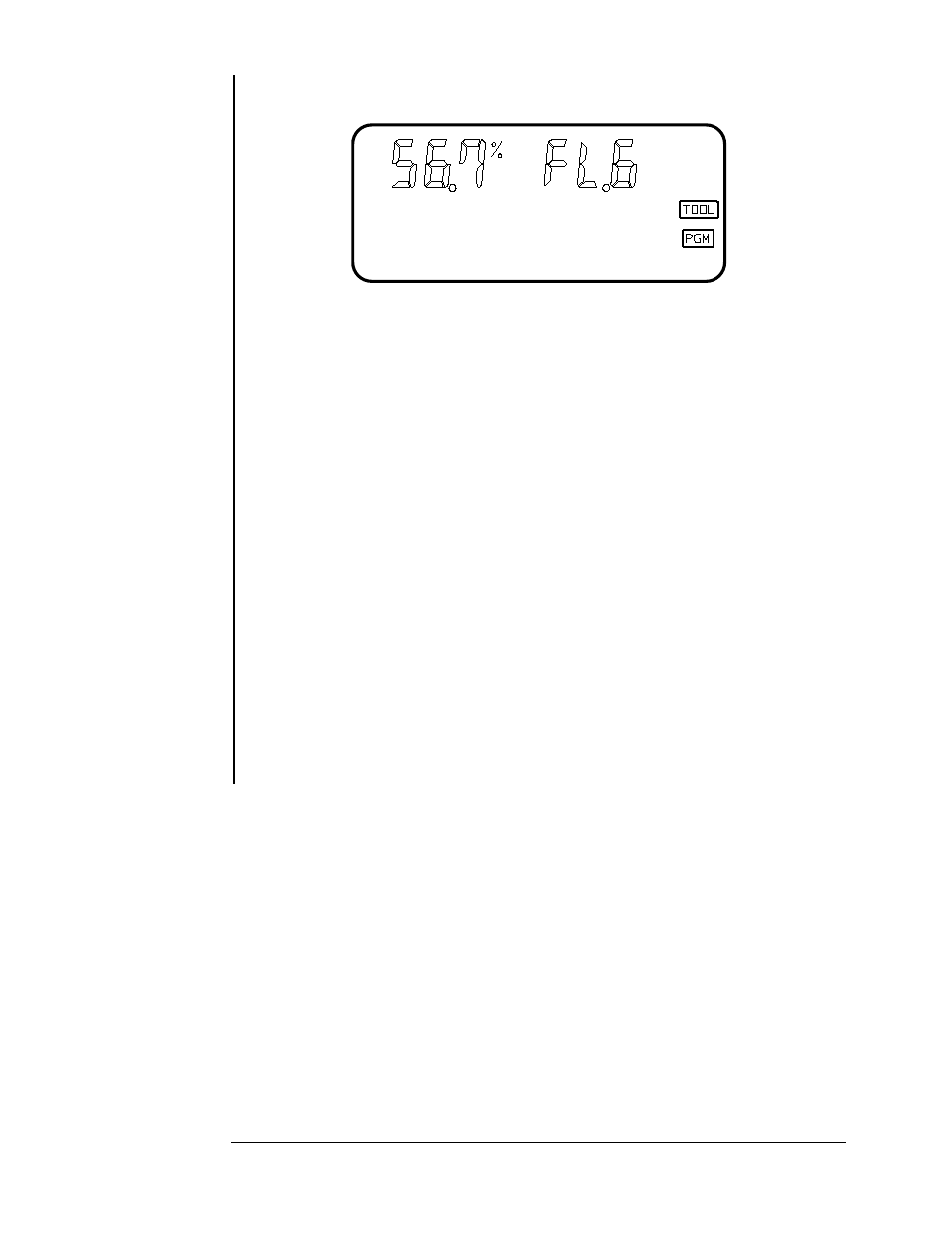

Figure 2.12: tooling parameter, Tooling factor parameter, User configuration switches – INFICON STM-100/MF Thin Film Deposition Monitor User Manual

Page 28: Section 2.5

TOOLING

Figure 2.12: Tooling Parameter.

LEGEND

TOOL

RANGE

10.0 to 399

UNITS

PERCENT

The TOOLING parameter is used as a correction factor to compensate

for geometric position differences between the location of the sensor and the

target substrate. Correction is required both the substrate and sensor see the

material source in an identical manner, unless for this case, the Tooling

Parameter is set to 100%. Generally, if the sensor is farther from the source

than the substrate, the tooling will be set to >100%. If the sensor is closer to

the source, the tooling will be set to < 100%. See Section 4.2 for calibration

information.

USER CONFIGURATION SWITCHES

On the rear panel of the STM-100 / MF a twelve selection configuration

switch is located. The settings of this switch allow the user to select various

system operational modes. All communications related variables are also set

here. Switches 1 thru 4 may be changed at any time and will have immediate

effect. Switches 5 thru 12 are only read at the time of power turn on.

Tooling Factor

Parameter

SECTION 2.5

OPERATION AND PROGRAMMING

Page 2 - 8