Housing-spindle sub-assembly, Dw2b integral brake check – JLG 450A_AJ Series II Service Manual User Manual

Page 66

SECTION 3 - CHASSIS & TURNTABLE

3-16

– JLG Lift –

3121180

Housing-Spindle Sub-Assembly

NOTE: Spray a light film of oil on all component parts during

assembly.

UNCONTROLLED OBJECTS CAN CAUSE EYE DAMAGE OR SERI-

OUS INJURY. ALWAYS WEAR EYE PROTECTION.

1. Press Bearing Cup (1C), position A, into Housing

(1E) using appropriate pressing tool (See back of

manual).

DO NOT USE EXCESSIVELY HIGH PRESSURE TO PRESS IN

STUDS OR HOUSING MAY CRACK. MAKE SURE HEAD OF STUD

CONTACTS FACE OF FLANGE ON HOUSING.

2. Turn Housing (1E) over and place into pressing

base. Press nine Studs (1H) into Housing (1E).

NOTE: Spray a generous amount of oil on bearings during

installation.

3. Press Bearing Cup (1C), position “B”, into Housing

(1E) using “B” Bearing Cone pressing tool (see back

of manual).

4. Place Bearing Cone (1D), into Bearing Cup (1C),

position “B”.

5. Grease Seal (1B) lip and press seal into Housing

(1E) using seal pressing tool (see back of manual)

until seal is flush with end of Housing.

6. Turn Housing (1E) over and lower onto Spindle (1A).

7. Install Bearing Cone (1D) into Bearing Cup (1C),

position “A”. and lightly press on Bearing Cup using

the “A” Bearing Cone pressing tool (see back of

manual) while rotating Housing (1E) in both direc-

tions to seat bearings.

8. Place Bearing Spacer (1F) on top of Bearing Cone (1D).

9. Using retaining ring pliers, install Retaining Ring

(1G) into Spindle (1A) groove. Make sure ring is

completely seated in groove.

NOTE: Extra bearing pre-load caused by pressing “A” Bear-

ing Cone (1D) must be removed. This should be

done by placing a flat piece of steel or a pressing

tool on the end of the spindle, and then lightly strik-

ing the tool with a piece of barstock. This should be

adequate to remove any additional bearing pre-load.

DW2B INTEGRAL BRAKE CHECK

1. Connect hydraulic line from hand pump to brake

port.

2. Check brake is set by trying to rotate Input Shaft (7).

This can be accomplished by installing an appropri-

ate tool (any tool that can locate on splines of the

Input Coupling (9), such as a mating splined shaft)

into Input Coupling (9)

3. Bleed brake. Increase hydraulic pressure gradually

while trying to rotate input until brake just starts to

release. Note this pressure. Make sure pressure falls

into appropriate range below:

4. Increase pressure to 3,000 psi and hold for 30 sec-

onds to check for leaks. Repair leaks if necessary.

NOTE: Make sure brake re-engages when pressure is

released.

NOTE: When done, make sure Input Coupling (9) is cen-

tered in Spindle (1A) to make installation of motor

possible without release of brake.

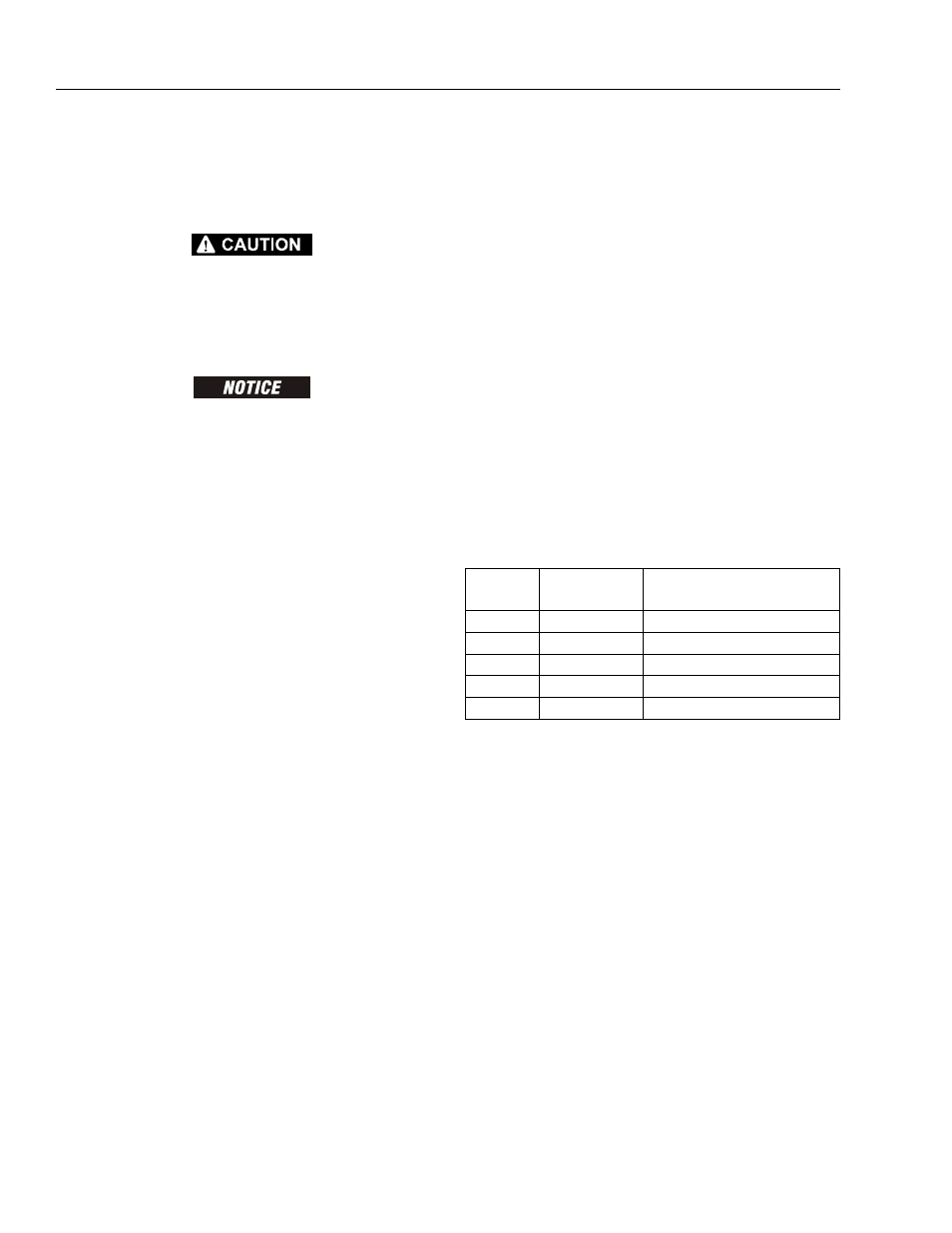

BRAKE

CODE

BRAKE P/N

JUST RELEASE

PRESSURE RANGE (psi)

A

902337

185-230

B

902341

155-192

C

902342

125-155

D

902343

93-115

E

902345

132-172